Thermowells and Bosses

Thermowells

- Features

- Technical Data

Thermowells and Bosses

Thermowells and Bosses provide reliable heat-transmission performance under high temperature, high pressure, and

corrosive conditions.

◎ Rugged mechanical construction ensures resistance to distortion under sharp temperature fluctuation conditions.

◎ Straight, stepped, and tapered shank designs are available.

◎ Standard instrument connection is 1/2 NPT, other connections are available on request.

◎ Materials include 316 SS, 304 SS, 321 SS, F91, F92, 316H SS, carbon steel, brass, titanium, alloy C-276 and alloy 400.

Technical Information Thermowells and Bosses

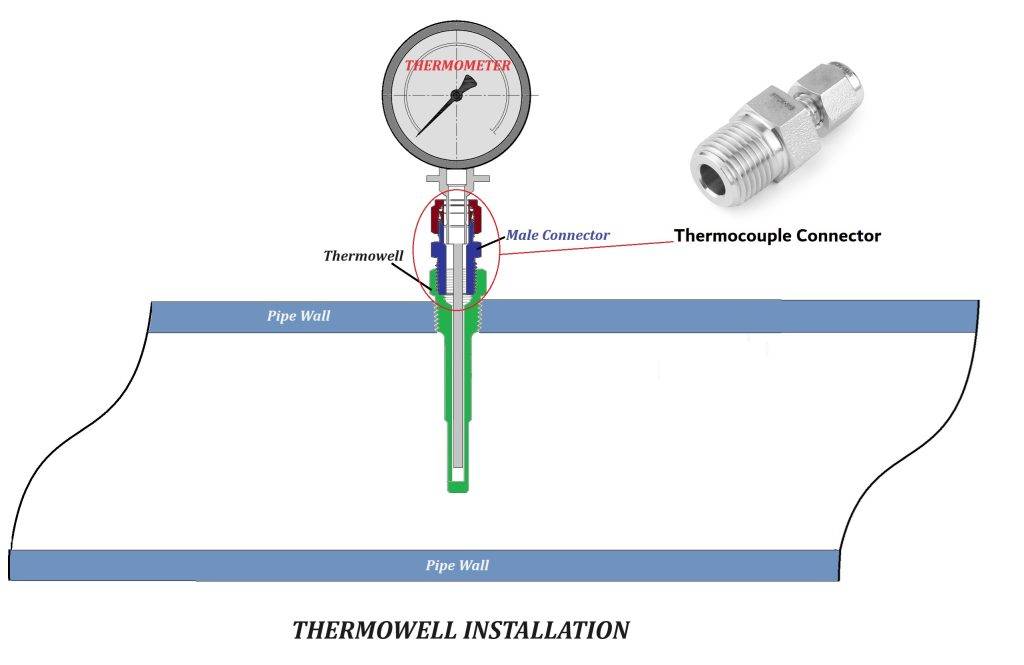

Thermowells and Bosses are hollow tubes closed off on one end and threaded at the other end. They are permanently placed into pipes, tanks or sumps so that temperature measurement probes can be inserted into the pipe to measure the contents temperature. The temperature of the contents is transferred through the wall of the thermowell. The thermowell prevents the contents of the pipe from escaping and holds in the pressure of pressurized pipes. Thermowells are sold by insertion length, the length of the thermowell inside the pipe.

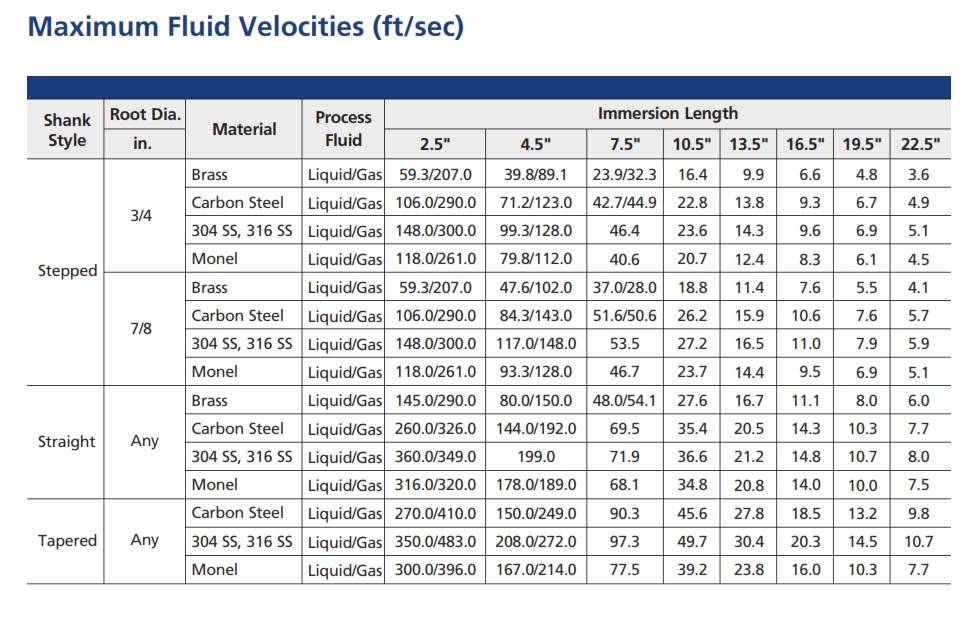

Velocity Ratings

When selecting a thermowell, take maximum fluid velocity rating into consideration to avoid failure due to resonance vibration, as well as connection type, insertion length, and bore diameter.

Please refer to the table below for the maximum fluid velocities:

How Thermowells are installed

Pull the probe out of the electrical box until the flare on the end of the probe, where the sensor wires come out, touches the immersion fitting. Insert the probe into the thermowell and push the immersion fitting towards the thermowell until the fitting’s threads engage the thermowell. Screw in the immersion fitting until it is just finger tight. The probe flair will move away from the immersion fitting surface. Carefully push on the temperature probe flair to be sure that the end of the temperature probe is bottomed out in the thermowell. The friction between the probe and the immersion fitting holds the probe against the bottom of the thermowell and ensures good temperature transfer.

316 SS, Thread Thermowells, Instrument Conn.:1/2in. FNTP, Process Conn.:3/4in. MNPT, 0.75in. Straight Shank, Bore:0.385in., insert length:4.5in.

TW Series Thread Thermowell,316 SS, Instrument Connection: 1/2″ Female NPT, Process Connection: 3/4″ Male NPT, Tapered Shank Type, Bore Diameter: 0.26″, Insertion Length: 2.5″

316 SS, TW Series Thermowells, Instrument Connection: 1/2″ Female NPT, Process Connection: 1/2″ Male NPT, Shank Style: Stepped with 0.625″ Root Diameter, Bore Diameter:0.26″, Insertion Length:5″

316 SS, Thread Thermowells, Instrument Conn.:1/2in. FNTP,0.875in. Tapered Shank, Bore:0.26in., insert length:8in.

316 SS, Thread Thermowells, Instrument Conn.:1/2in. FNTP,0.875in. Tapered Shank, Bore:0.385 in., insert length:8in.