Hex Bar Stock Ball Valves BR Series

Hex Bar Stock Ball Valves-BR Series

Features

◎ Working pressure up to:

BR Series: 1000 psig (69.0 bar)

◎ Working temperature:

BR Series:-20°F to 450°F (-28°C to 232°C)

◎ Compact and economical design

◎ Free floating ball design for seat wear compensation

◎ Bi-directional flow

◎ Low operating torque

◎ A variety of end connections available

◎ Blowout proof stem

◎ Handle color options available

◎ Leak-tight performance testing with nitrogen or compressed air for every valve at the rated pressure to meet the requirement of no visible leak

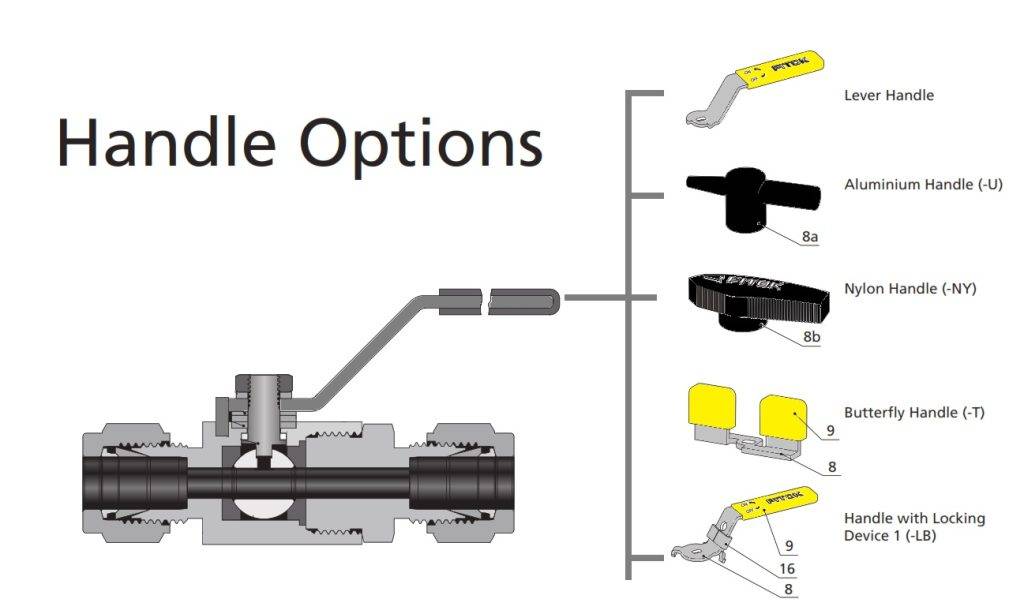

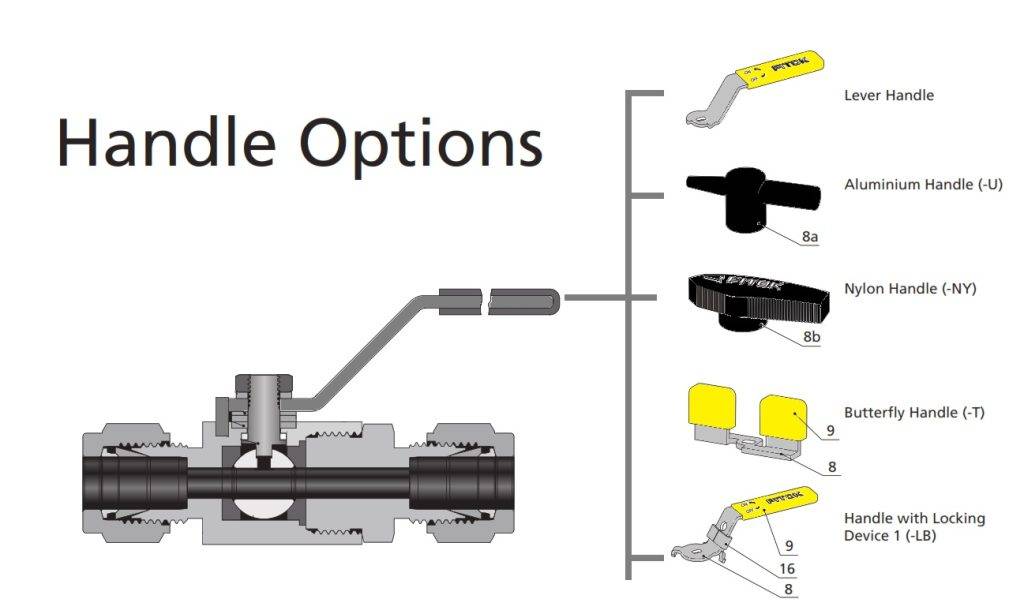

Handel Options

◎ SS with Yellow Vinyl Cover

◎ SS with Red Vinyl Cover

◎ Black Aluminium

◎ SS with Blue Vinyl Cover

◎ Black Nylon

The working pressure of valves is restricted by materials of the valve body and seat, as well as end connections. When choosing a valve for your applications, please refer to the above Temperature vs. Pressure Curves and the pressure rating in the dimension table. The minimum value shall be the pressure rating of the valve.

When the connection type of valves is FITOK double ferrule tube fitting, the working pressures of the valves are related to the wall thickness of tubing applied. For specific working pressure of the valves.

Cleaning and Packaging:

FC-01: Standard cleaning and packaging for general industrial procedures.

FC-02: Special cleaning and packaging for wetted system components to ensure compliance with product cleaning requirement of ASTM G93 Level C

◎ SilcoNert 2000 (Sulfinert) Coating: Wetted metal components SilcoNert 2000 (Sulfinert) coated.

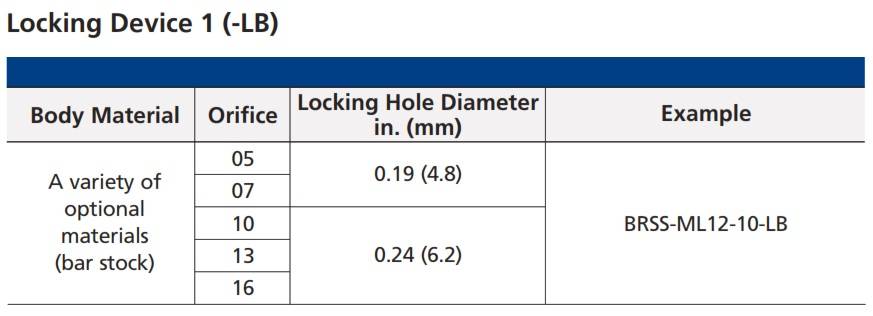

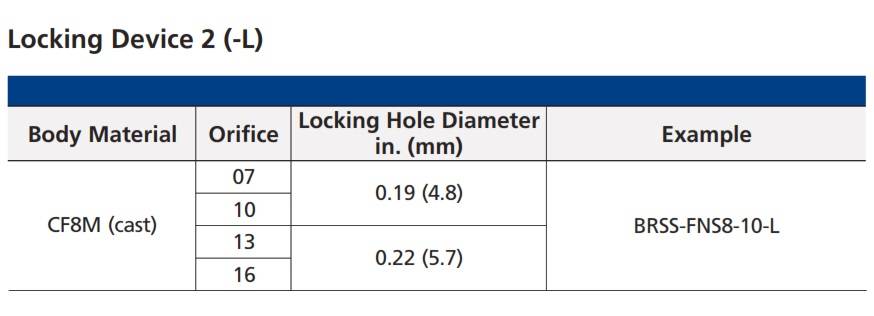

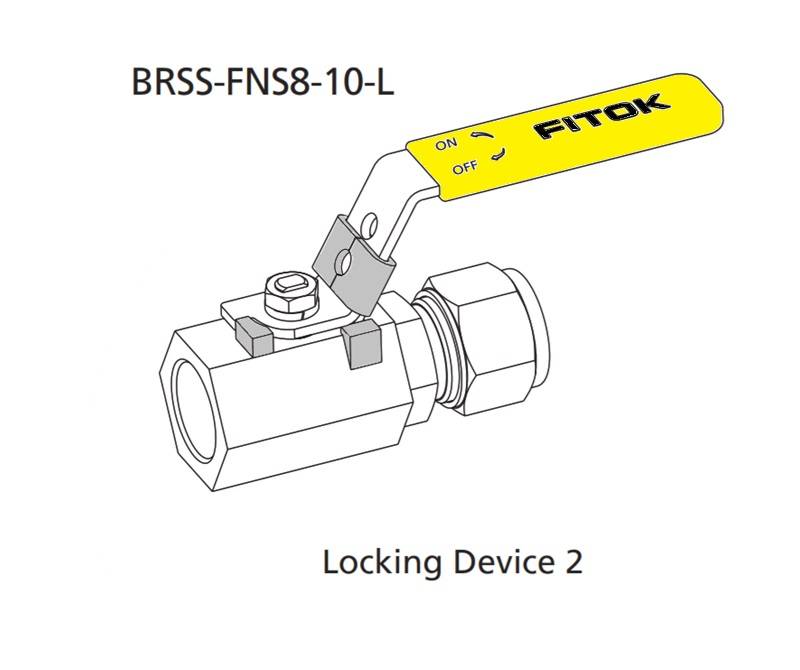

Locking Device 1 and Locking Device 2 can lock BR series valves.

For valves with orifice sizes 05, 07, and 10, the locking hole diameter is 0.19 in (4.8 mm);

For valves with orifice sizes 13 and 16, the locking hole diameter is 0.22 in (5.7 mm).

To order a ball valve with Locking Device 1, add -L to the valve ordering number.

Example: BRSS-ML12-10-L

Hex Bar Stock Ball Valves BRC Series

Hex Bar Stock Ball Valves-BRC Series

Features

◎ Working pressure up to 2000 psig (138 bar)

◎ Working temperature: -65°F to 400°F (-54°C to 204°C)

◎ Compact and economical ball valve designed for industrial applications

◎ Blowout-proof stem minimizes the risk of valve failure due to stem displacement or loosening

◎ Free-floating ball design allows the ball to be pushed against the seat by fluid pressure, ensuring a tight and reliable seal

◎ Bidirectional flow

◎ Low-torque handle enables easy and smooth operation

◎ A variety of end connections available

◎ Handle color options available

◎ Each valve is tested for internal and external leakage using nitrogen or compressed air at rated working pressure before shipment

Handel Options

◎ SS with Yellow Vinyl Cover

◎ SS with Red Vinyl Cover

◎ Black Aluminium

◎ SS with Blue Vinyl Cover

◎ Black Nylon

The working pressure of valves is restricted by materials of the valve body and seat, as well as end connections. When choosing a valve for your applications, please refer to the above Temperature vs. Pressure Curves and the pressure rating in the dimension table. The minimum value shall be the pressure rating of the valve.

When the connection type of valves is FITOK double ferrule tube fitting, the working pressures of the valves are related to the wall thickness of tubing applied. For specific working pressure of the valves.

Cleaning and Packaging:

FC-01: Standard cleaning and packaging for general industrial procedures.

FC-02: Special cleaning and packaging for wetted system components to ensure compliance with product cleaning requirement of ASTMG93 Level C

◎ SilcoNert 2000 (Sulfinert) Coating Wetted metal components SilcoNert 2000 (Sulfinert) coated.

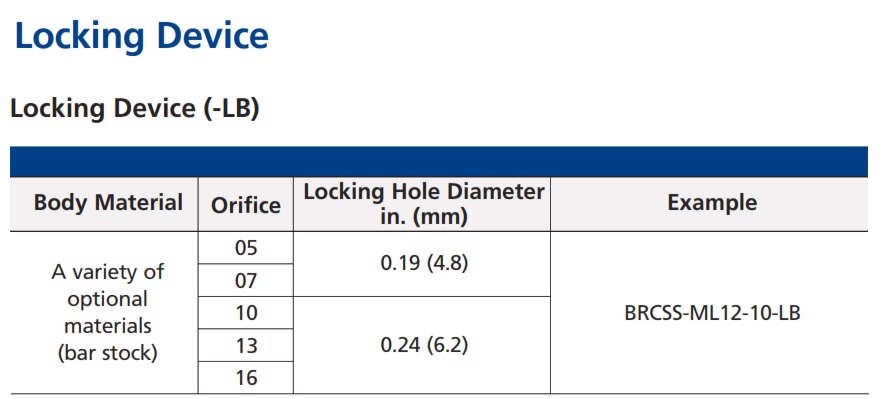

Locking Device can lock BRC series valves.

The locking device is only applicable to lever handles. For other handle types requiring a locking device.

Example: BRCSS-ML12-10-LB