Terms and Definitions : Selecting and Install Hose Assembly

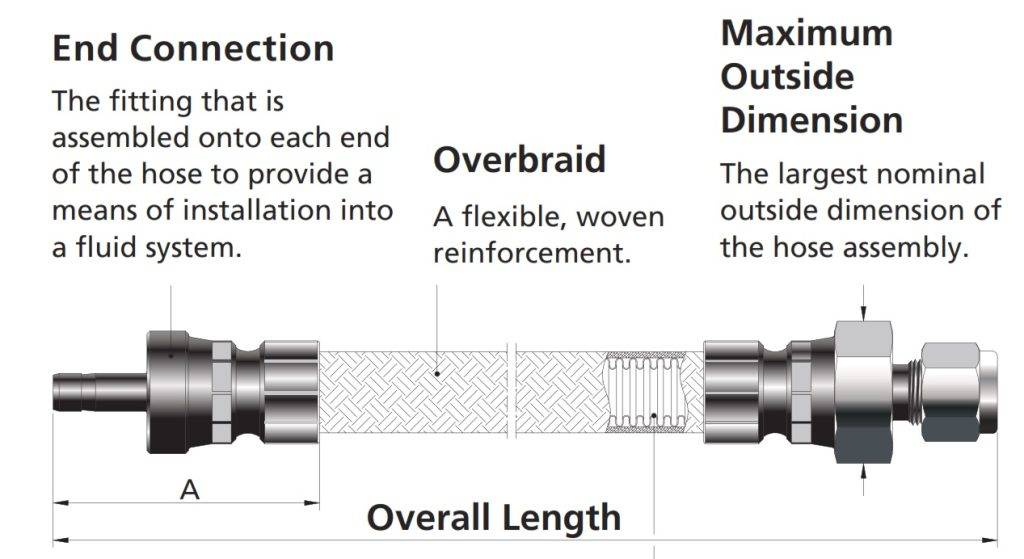

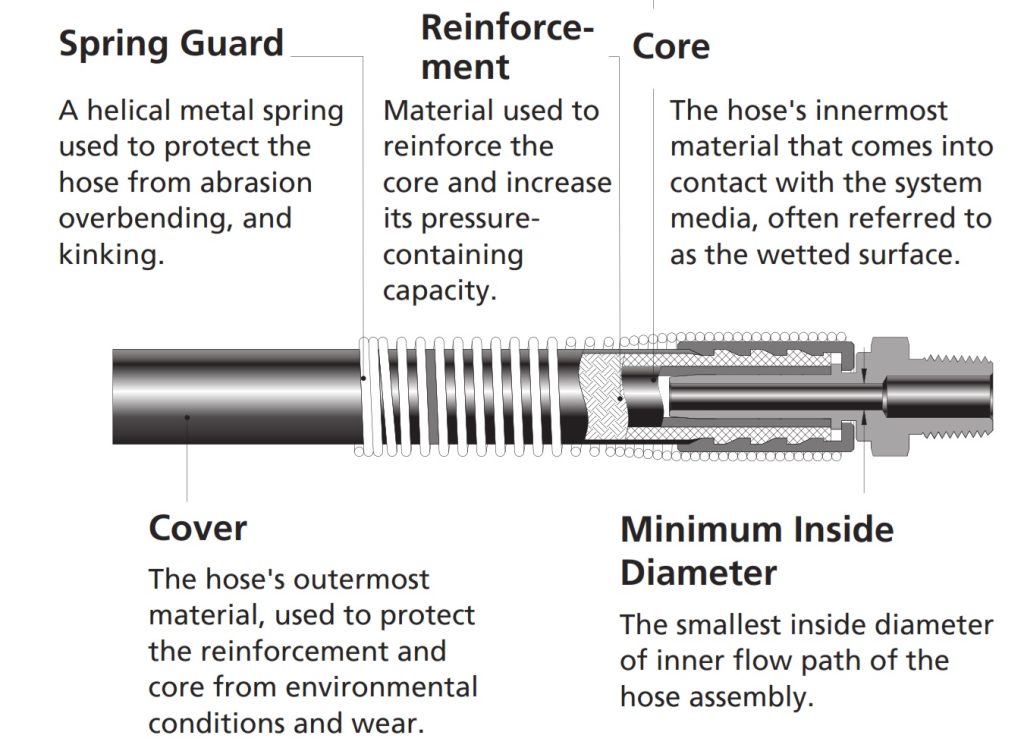

Hose

A multiple-layered flexible conduit through which fluid is conveyed from one point to another.

Nominal Hose Size

An approximation of the hose inside diameter.

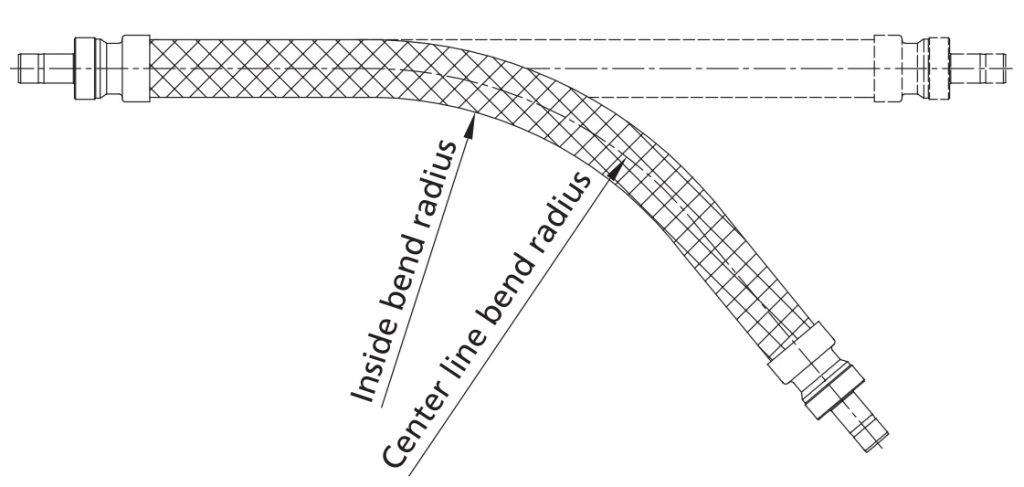

Bend Radius

The radius of the bent section of a hose, measured to the center line or inside of the curved section.

Minimum Dynamic Bend Radius

The smallest bend radius that a hose is allowed to perform in applications where the hose undergoes dynamic bending and position changes.

Minimum Static Bend Radius

The smallest bend radius that a hose is allowed to perform in applications where the hose is stationary without any movement in any plane.

Flexibility

The relative ease or difficulty of bending a non-pressurized hose assembly.

Burst Pressure

The pressure at which leakage occurs in a laboratory burst test.

Permeation

The movement of a liquid, gas, or vapor through a solid. All materials are permeable to a certain degree and must be tested for application compatibility before installation.

Considerations for Selecting a Hose Assembly Solution

Terms and Definitions

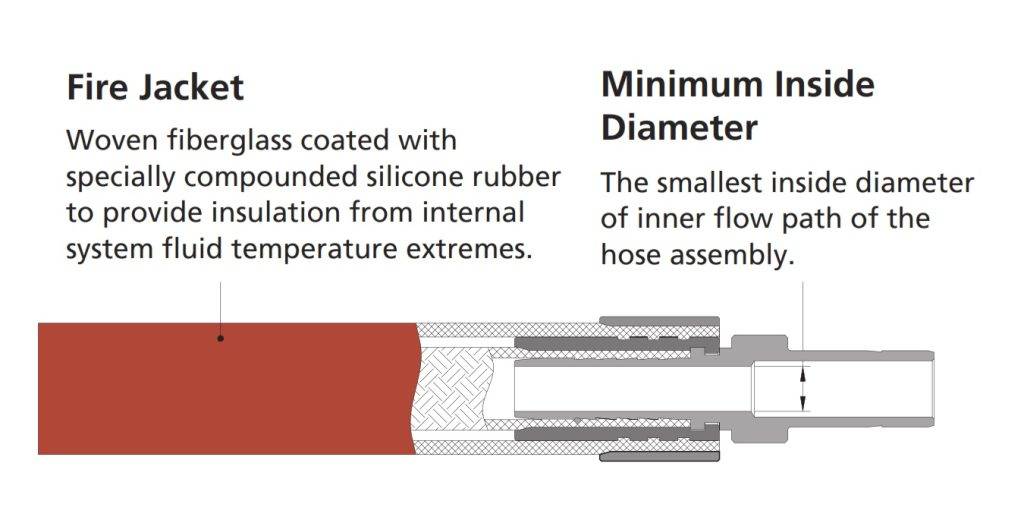

Temperature

Identify the minimum and maximum temperatures the hose assembly will be expose to in the system media and environment.

Pressure

Identify the minimum and maximum pressures (or vacuum) within and outside the hose assembly.

Material

Identify the system media and the environment that the hose assembly will be expose to. This will help determine the materials best suited to the application demands.

Movement

Confirm whether the hose assembly will be install in dynamic applications so that this will require different considerations than a static application.

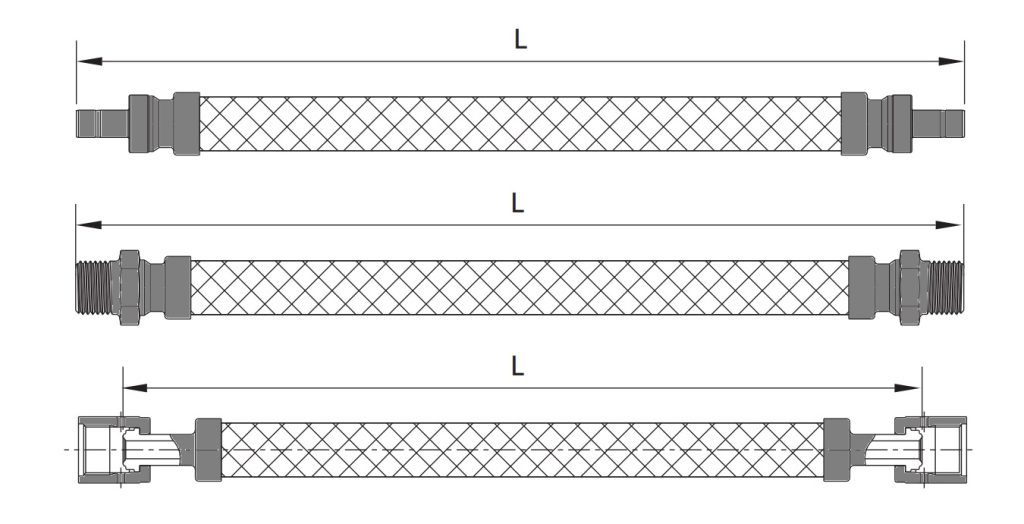

Length

Determine the most likely route for installation of the hose, use this to identify required length.

Note: Different types of hoses vary in measuring position. For hoses with pipe fittings, length loss due to threading into the mating fitting should be taken into account.

Installation and Use Guide

Warning

Product failure or improper use may pose a threat to your personal safety and property.

Inspection

Inspect whether the hose length and layout are reasonable whether hose or surface is free of defects and damage prior to installation. Establish an inspection schedule based on system application and replacement history.

Vibration

Evaluate the amount of system vibration when selecting a hose. Metal hose may not be appropriate for systems with constant or severe vibration.

Length

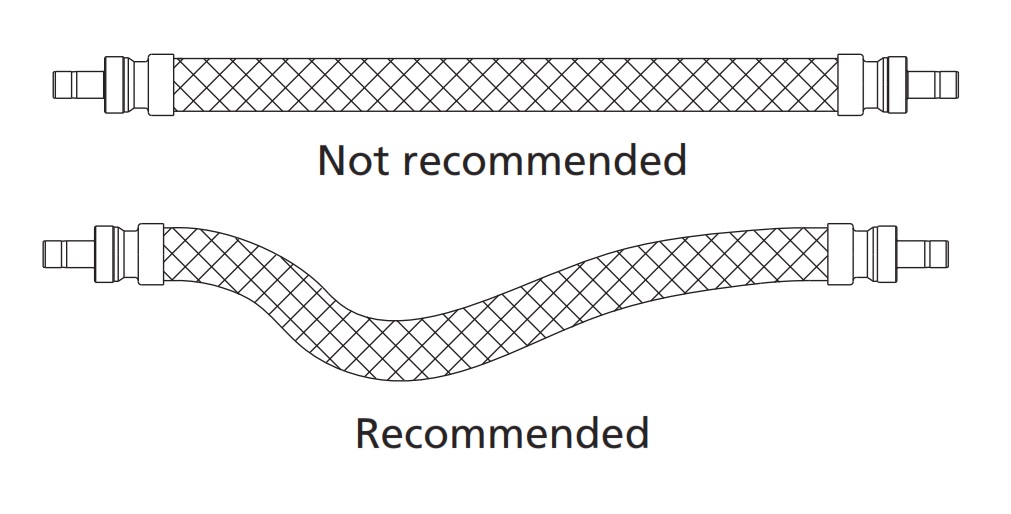

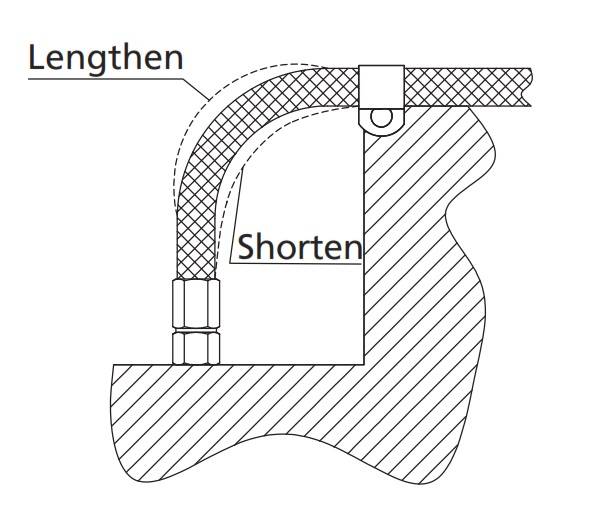

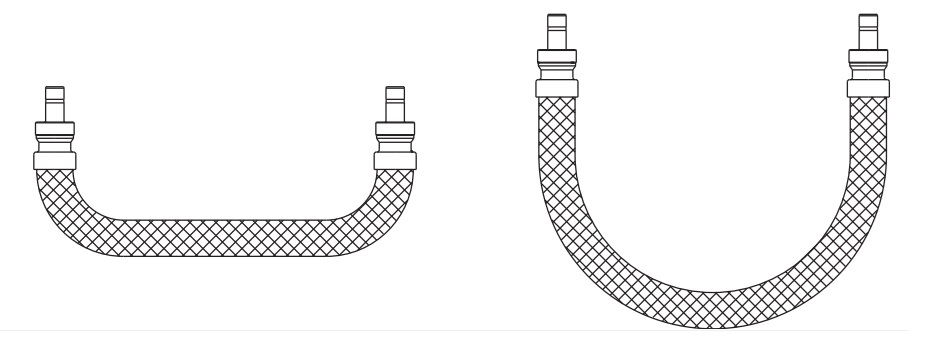

Consider hose movement, system pressurization and thermal expansion when identifying hose length. Installing hose that is not long enough to accommodate these factors may shorten hose life.

System Pressure Changes

Use sufficient hose length to accommodate system pressure changes. Do not connect high pressure hoses and low pressure hoses together.

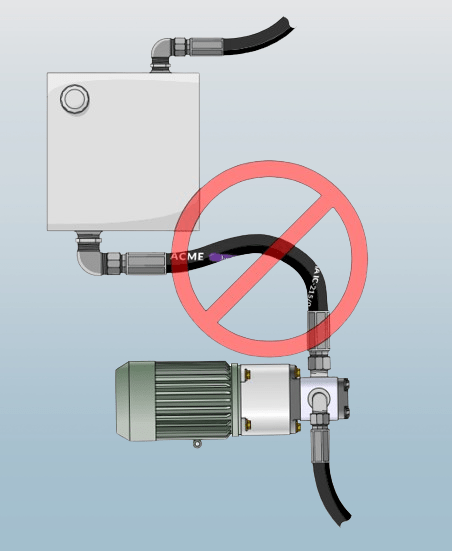

Hose Strain

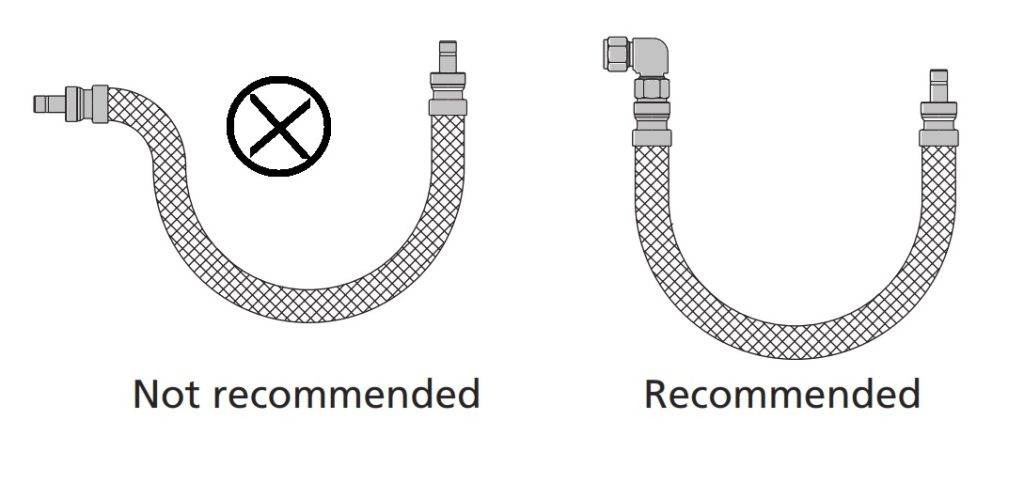

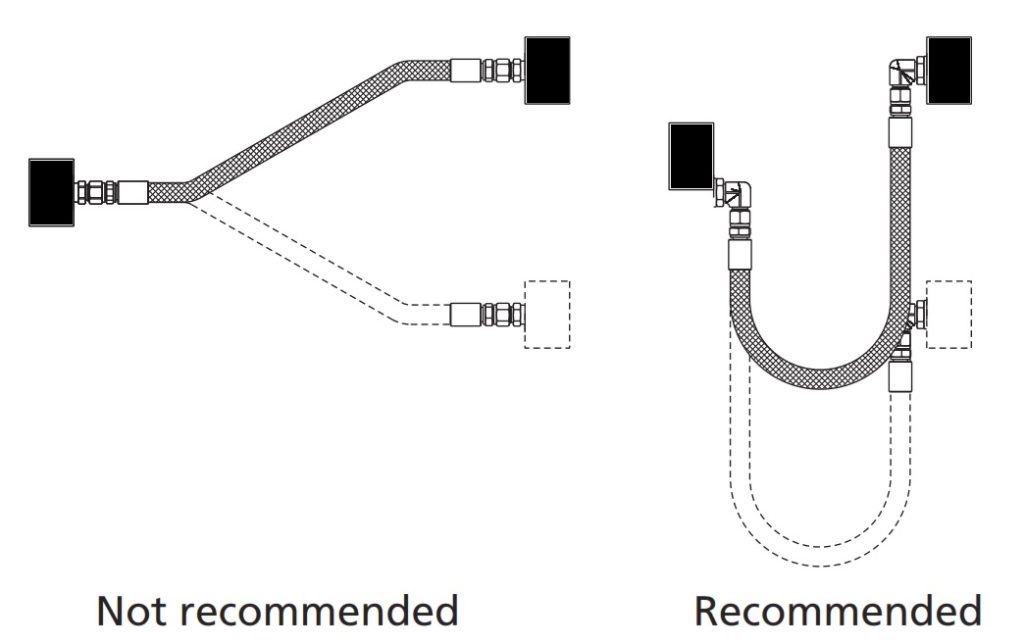

Elbows and adapters can be use to relieve hose strain.

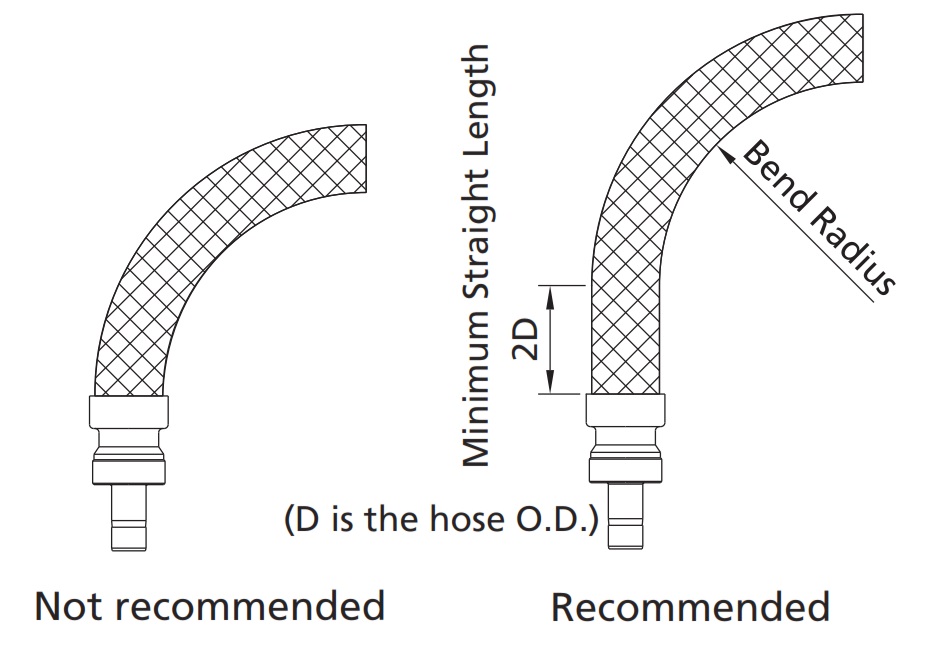

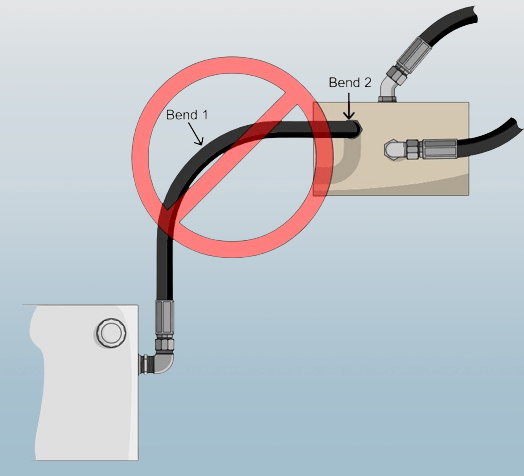

Minimum Bend Radius & Minimum Straight Length

Follow minimum bend radius requirements for your hose.

Installing hose with smaller bends may kink hose and shorten hose life.

Maintain the minimum straight length for bent section, otherwise, hose rupture or leakage may result from bending too close to the hose/fitting connection.

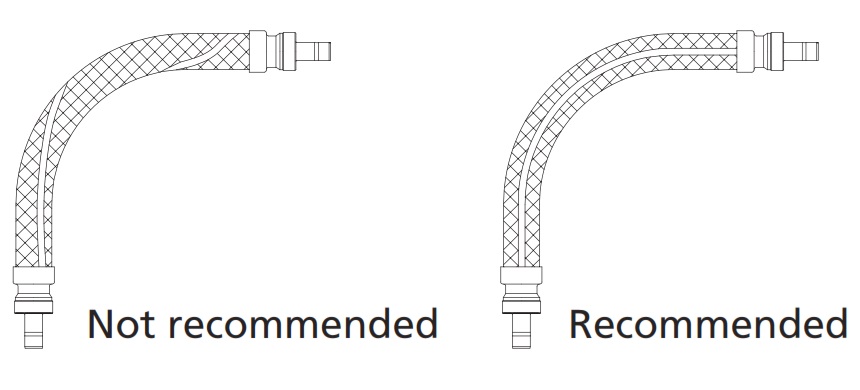

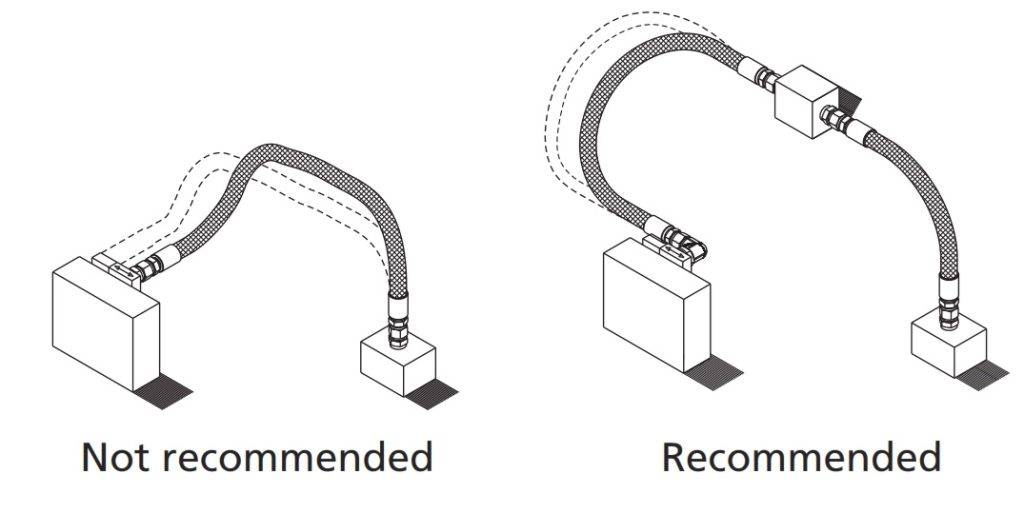

Twist Avoidance

Avoid twisting the hose assembly and causing stress that may affect its use.

Pay attention to the layline to make sure that is not spiralling around the house as you tighten the fittings. The use of fittings with swivels also helps to prevent twisting.

When routing a hose, twisting becomes much more likely if you introduce compound bends. A compound bend refers to a hose that makes a bend in more than one plane. If your hose must make a compound bend, you should speak to an installation professional. They may have a helpful recommendation to reduce the chances of hose twist.

Bending in One Plane

Bend the hose in one plane only so as to avoid twisting. For a compound bend, use multiple hose pieces or other isolation methods.

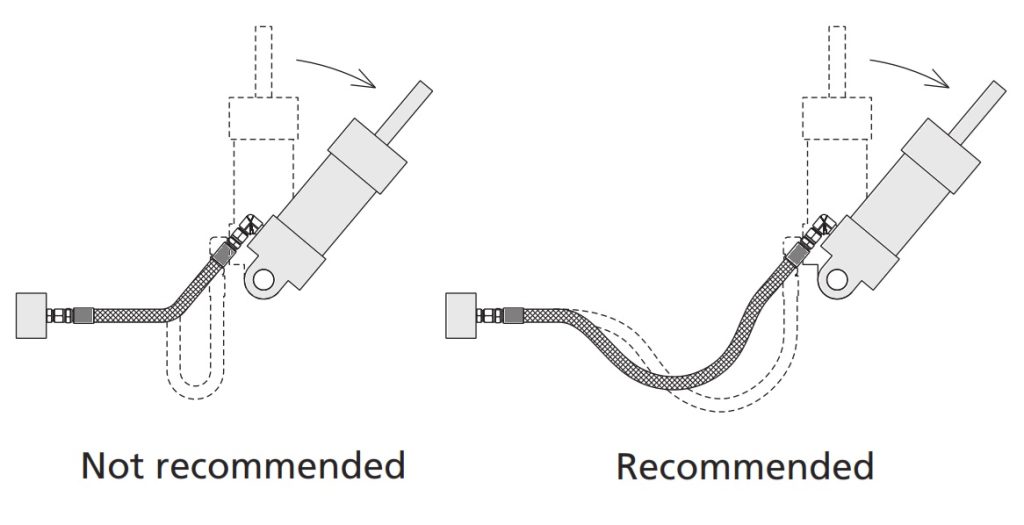

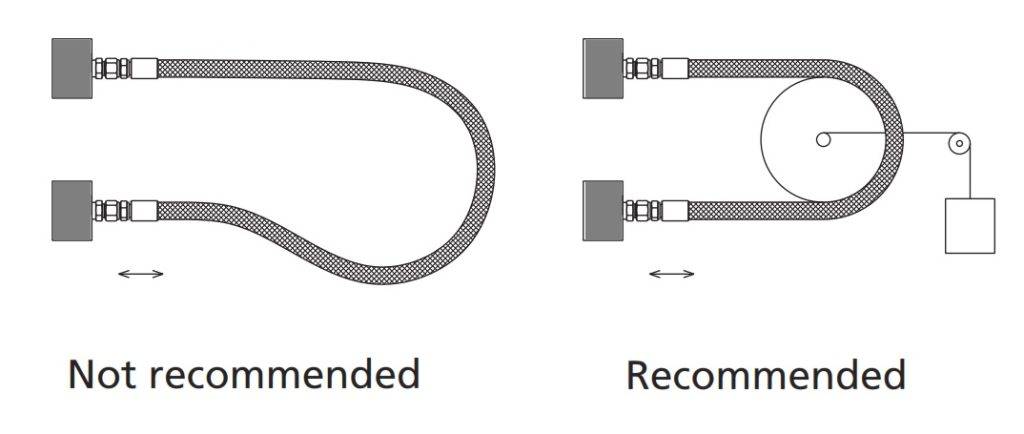

Motion Absorption

Distribute movement and prevent bends smaller than the hose’s minimum bend radius by ensuring sufficient hose length.

Elbow-connect hoses are better suit for vertical movement than hoses connect with straight fittings.

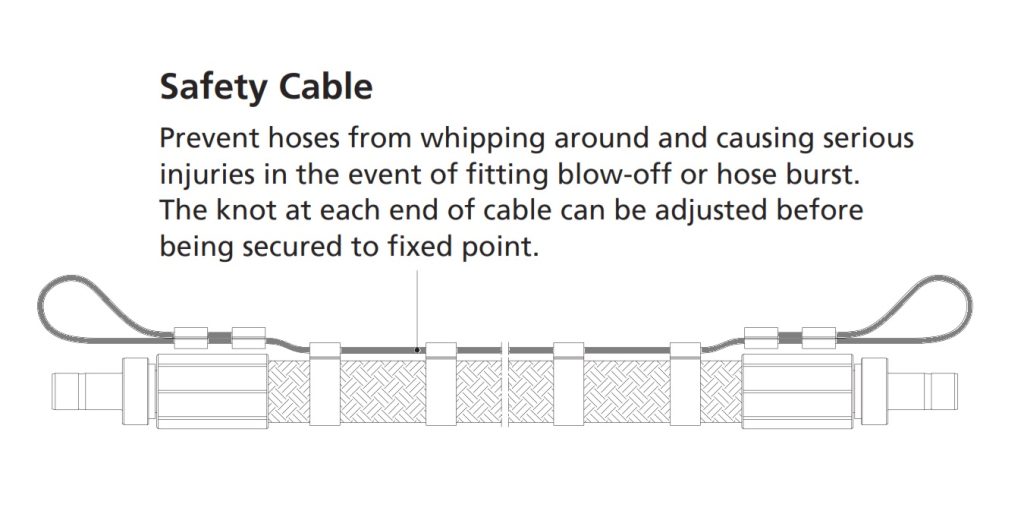

Necessary Limits and Protection Devices

Install necessary limits and protection devices to facilitate hose movement and avoid twisting.

Our Product Hose provide variation pressure for Medium and High Pressure and with Variation material from Metal and Thermoplastic Hoses. Our Product Hoses.