Home > Products Categories > Double Block and Bleed Valve

Introduction about Double Block and Bleed Valve

Space in these offshore locations is always at a premium and the design of piping systems and their associated components must therefore be more compact. There are structural constraints that are also very important, such as to keep the structure as light as possible, and there are obvious benefits from making components smaller and lighter. The situation has led to the modification of the patterns of valve components to incorporate savings in space, weight, and labor costs where possible, while still retaining the original function of the valve.

The process calls for a double block and bleed isolation philosophy, these valves are used for two functions:

1. Instrument double block and bleed (small size) for pressure connections, chemical injection, sampling, vents and drains, etc.

2. In-line double block and bleed (large size) for process isolation.

Double block and bleed isolation requires two in-line isolation valves and a bleed valve, used to drain or vent trapped fluid between the two closure elements.

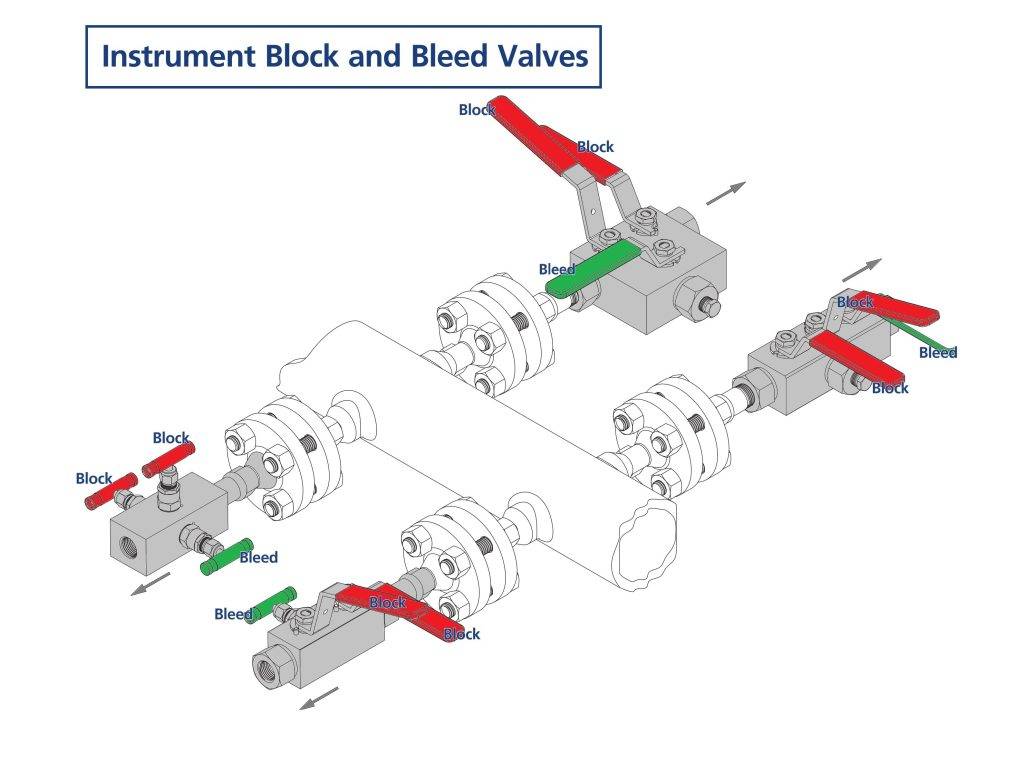

1. Instrument Double Block and Bleed Ball Valves

These small bore compact valves are generally used to isolate instrumentation such as pressure indicators (PIs) and level gauges (LGs) and they come in a variety of combinations. The two isolating valves are usually of a quarter-turn ball type, with either soft or metal-metal seats depending on the design conditions of the process fluid. The smaller, usually – or – bleed valve can be a globe, needle, or in some cases a ball type design.

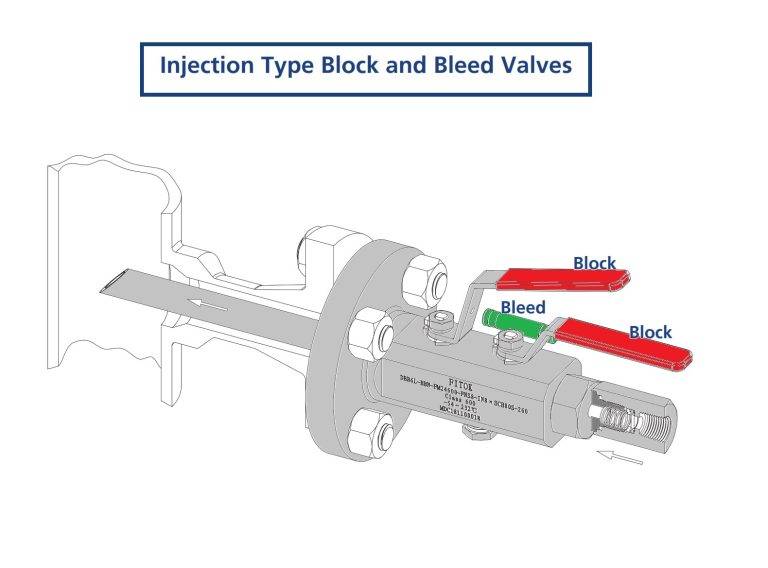

Chemicals Injection

These compact valves can also be used for injecting chemicals or sam-pling process fluid by adding straight tubing onto the bore of the flange face.

When assembled onto a mating flange this quill enters into the pro-cess flow and chemicals can be introduced through the valve and then the tube, which is in the process flow. An additional in-line poppet type check valve is incorporated in the compact valve to prevent reverse flow and pro-cess fluid contaminating the chemical source.

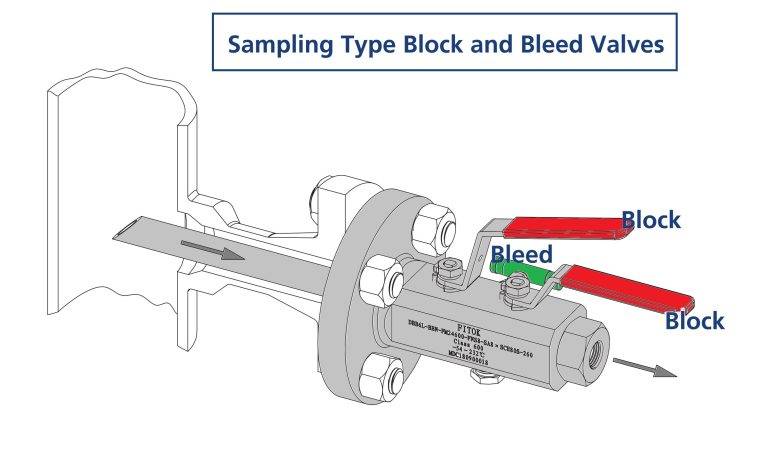

Sampling Systems

For sampling the reverse is applied and samples can be removed from the process fluid, via the quill, through the open in-line valves and then collected in a sample bottle, which can be taken away for analysis.

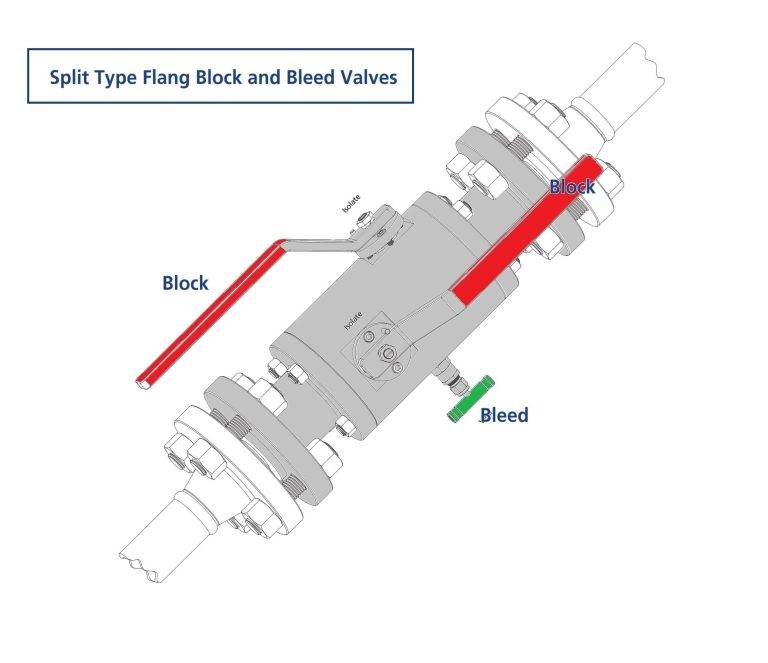

2. In-Line Double Block and Bleed Ball Valves

These compact valves can be supplied in a similar number of end connections as the smaller instrument double block and bleed versions. These in-line valves are available up to around 8″ and pressure ratings up to and including ASME 2500 lb

Double Block and bleed Valve that combines one or more lock/isolate valves, usually ball valves, and one or more bleed/vent valves, usually ball or needle valves, into one component for interface with other components for pressure measurement transmitters, gauges, switches, etc where used in hydraulic fluid system. The purpose of the block and bleed manifold is to isolate or block the flow of fluid in the system therefore the fluid from upstream of the manifold does not reach other components of the system that are downstream.

Double Block and Bleed, DBB Series

Instrument Double Block and Bleed Valves

Threaded or one-piece forged body

Optional port sizes and thread forms available in addition.

Orifice all-ball-valve configuration, ball-and-needle-valve

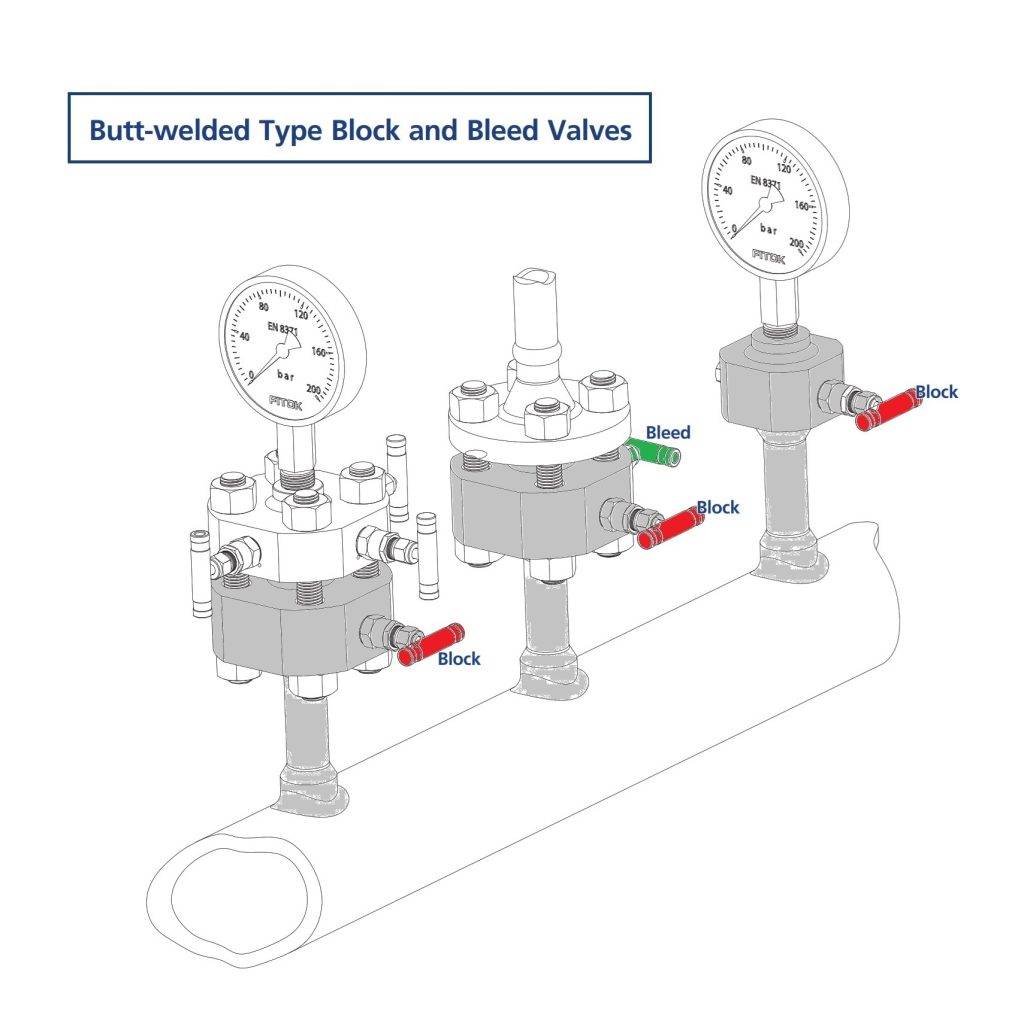

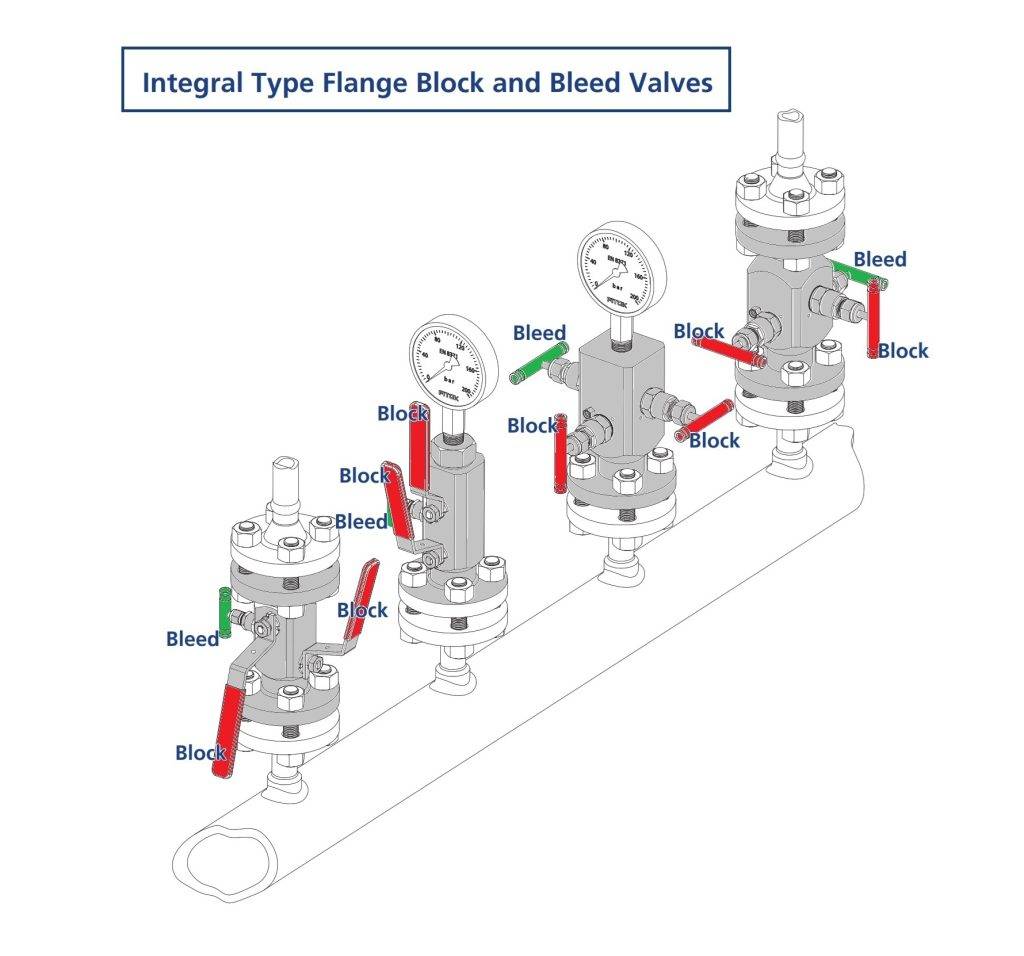

Flange Double Block and Bleed Valves

One piece forged body

Minimizes potential leak paths

Piping and instrument valves in one body

1/2 female NPT standard outlet

Double Block, DB Series

DB Series: Double Block Valves

Piping and instrument valves in one body design

1/2 female NPT standard outlet

Orifice: 0.16 in. (4 mm) is standard, 0.25 in. (6.4 mm) and 0.38 in. (9.5 mm) are available for some flange sizes

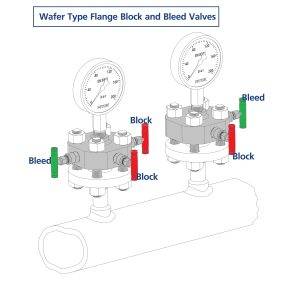

Single Block and Bleed, BB Series

Flange Double Block and Bleed Valves

One piece forged body

Minimizes potential leak paths while used in piping application pressure

Piping and instrument valves in one body

1/2 female NPT standard outlet

Single Block, SB Series

Monoflange Single Block Valves

Piping and instrument valves in one body

1/2 female NPT standard outlet

Orifice: 0.16 in. (4 mm) is standard, 0.25 in. (6.4 mm) and 0.38 in. (9.5 mm) while available for some flange sizes

Others Block and Bleed Style