High Pressure Fittings

High Pressure Fittings Application

High Pressure fittings product often said as Subsea fittings and Many Application in Deep sea equipment requires resistance with high pressure and resistant to corrosives caused sea water. High pressure valves usually have a pressure specification above 10000 psig until 60,000 psig.

The High Pressure Fittings also many application in Oil and Gas Industry

- Well Head Control Panels

- Corrosion resistant 316 stainless steel materials

- Innovative design to maintain leak-tight performance at a variety of pressures

- Creates a reliable, leak-tight system when paired with FITOK tube fittings and tubing

- Chemical Injection Skids

- Highest quality seal materials ensure a longer product life when cycling harsh chemicals Consistent leak-tight seal improving worker safety

- Low actuation torque makes it possible to reduce costs and save space when complimenting the valve with a smaller, less powerful actuator

- Hydraulic Power Units

- Strain-hardened stainless steel for compact design and superior strength

- Patent-pending sealing design for low-pressure sealing after high pressure operation

- Subsea Work Over Panels

- Maintenance skids that take over the supervisory control of the well head control panel when subsea well head maintenance is required

- Emulate the control of the subsea and safety shut-in process valves

- May also include an integral HPU

- Alternative fuel

In the alternative fuels, while alternative fuel systems require medium pressure ratings up to 15,000 psig. These systems are expect to include hydrogen fuel cell applications, where the hydrogen must be compressed to 10,152 psig. Due to temperature rise during filling and the thermal expansion of hydrogen. Filling pressure can reach upwards of 12,327 psig and so that 10,152 psig will maintained when the system temperature returns to ambient.

How does it work High Pressure Fittings :

High Pressure Fittings have unique end connection is not like others system connection for tube systems. Furthermore we will explain below :

- High Pressure Fittings Double Ferrule with Pressure up to 15,000 Psig: Using a Grid system, and namely Gland Collar Threads and Body Fittings

Medium High Pressure Fittings and can reach Pressure up to 20,000 Psig. There are two types of grip systems that is Nut system, Body ferrules, Nut, and ferrules. In addition the Grip Gland, Collar, Body system.

20D Series Double Ferrule Tube Fittings

20M Series Medium Pressure Fittings

60 Series High Pressure Fitting can reach pressure up to 60,000 Psig. Not using Ferrule systems but using a Grid system, namely Gland Collar Threads and Body Fittings.

In this case we explain how they to grip tube of the high pressure connection system works due to medium pressure 15,000 Psig :

Tube grip is accomplish by both front and back ferrules that grip onto the tube during installation. This robust tube grip allows for working pressures up to 15,000 Psig and especially over a wide range of installations. The tube grip works on both fully annealed heavy wall and cold drawn 1/8 hard tubing, which allows more flexibility applications.

Installation Instructions Medium & High Pressure

Installation of DHL Series Tubing Connections

For Tube O.D. 1/8″, 1/4″, 3/8″ and 1/2″

Without Manual Presetting Tool

- Put the nut and ferrules onto the tubing in fixed sequence and orientation (Fig. 1).

- Insert the tubing into the fitting body or the valve. Finger tight the nut. Make sure that the tubing rests firmly on the shoulder of the fitting body or the valve (Fig. 2).

- Mark the nut and the fitting body or the valve (Fig. 3).

- Hold the fitting body or the valve steady. For tube O.D. 1/8″, tighten the nut 1 1/4 turns with a wrench. For tube O.D. 1/4″, 3/8″ and 1/2″, tighten the nut 1 1/2 turns with a wrench (Fig. 4).

Installation of DHL Series Tubing Connections

Connection Installation example MF

Connection Installation example HM

High Pressure Tube

High Pressure Tubing

- Annealing seamless or Cold drawn 1/8 hard tubing

- Heavy wall annealed tubing

- Heavy wall 2507 tubing

- Material Grade S31600/S31603

- Coned and Thread Nipple 60 Series

- Working Pressure are calculated from an S Value of 60,000 Psi (413 Mpa) for ASME B31.3 Chapter IX High Pressure Piping

- Heavy-Duty SAE/MS Pressure Ratings end connections according to SAE J1926/2

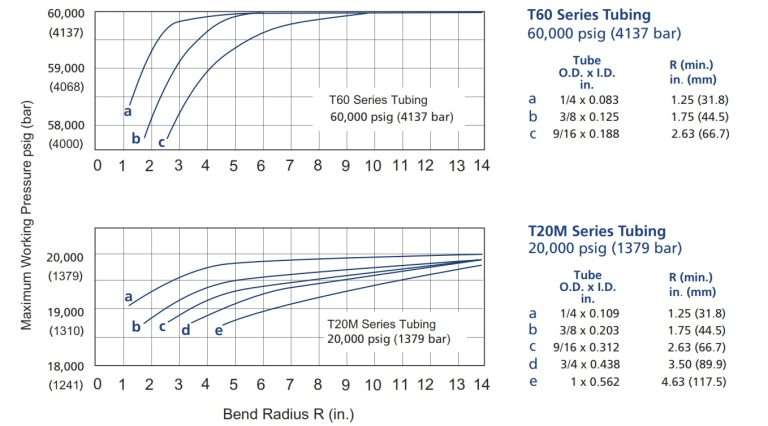

Working Pressure vs. Bend Radius Curve T20M and T60 Series Tubing (316/316L SS)

High Pressure Valve

High pressure valve in general have type Ball valve and Needle valve, in addition the following is an explanation of the two types of valves and their construction.

- Pressure Ball Valve construction Feature :

- High Pressure Ball Valve can used from pressure from 15,000 psig until 60,000 psig.

Below we descript the detail inside of High Pressure Ball Valve, it inside is the components that comprise the patent-pending “direct-load” seal design.High Pressure High Pressure Needle Valve construction Feature : - Metal-to-metal seating to achieve ideal shutoff, longer stem/seat service lifetime for abrasive flow,excellent corrosion resistance and greater durability for repeated on/off cycles

- Non-rotating stem and bar stock body design

Construction High Pressure Needle Valve

Construction High Pressure Ball Valve

Setting conditions:

• Inlet temperature 649℃

• Inlet flow velocity 2 m/s

Result :

• Stuffing box temperature less than 400℃

• Handle temperature less than 70℃, operate directly by wearing gloves

Subsea Valve Application

Subsea valves used in sub-marine environments. Range depth from shallow water to down until depth of 75 meters to deep water with down to 3500 meters. Various industries use subsea valves, with the oil and gas sector accounting for the majority.

When operating valves in a subsea environment , we will need some options. Used of electric or hydraulic or manual actuation is most common. The type of actuation is always dependent on the system and the application.

For manual and ROV manipulated valves in additional. So FITOK provides an API 17H compliant valve handle. Meets the operating standards of ROV manipulators and ROV interface tooling and we called paddle assemblies. That allow an ROV to function the valve.

The material is used is a high grade stainless steel has excellent corrosion resistance and strength for the harsh subsea environment. So Equipped with a limit design and paddle assembly is prevents ROV over torque from affecting with the normal use of the valve. With a modular approach and the paddle design, Its will work with nearly every brand and configuration for subsea instrument valves on the market.

FITOK provides a wide range of subsea valve products base in the US capable of being function with preferred methods. The latest addition of a manufacturing with base in the U.S. Expanded the production, testing and delivery capabilities for subsea products.

We are PT. Solutec daya Mandiri is ready to serve you to provide high pressure valve include application to your fluid systems. Please Contact us.