Male Connector

Male Connector merupakan salah satu alat kelengkapan tubing dan banyak digunakan untuk penghubung antara tubing dan peralatan lainnya dengan menggunakan ulir atau welding. Ulir pada male connector Tapered merupakan adaptor untuk menahan kekuatan tekanan fluida.

Male Connector jenis bulkhead

Beberapa aplikasi penggunaan Male Connector untuk lubang panel adalah type Type Bulkhead tube fittings dan tersedia dengan bermacam-macam dan variasi end koneksi seperti sebagai berikut :

Male connector Bulkhead.

Tube fitting Male 37° Flare(AN) AN Bulkhead.

Female connectors Bulkhead.

Reducing unions Bulkhead.

Unions Bulkhead.

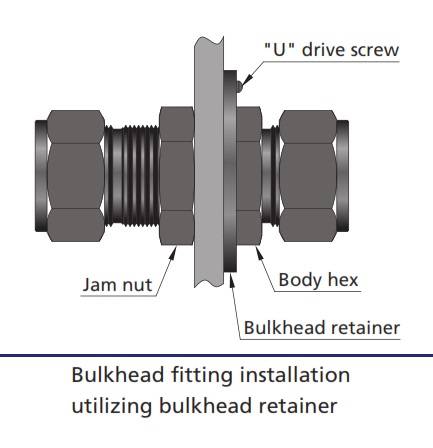

Berikut di bawah ini aplikasi Bulkhead Male connector yang dipakai pada panel dan dikunci menggunakan Retainer.

Cara Installasi Bulkhead Male Connector

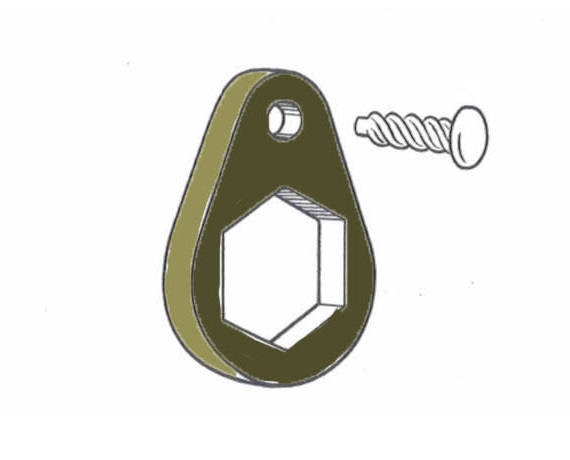

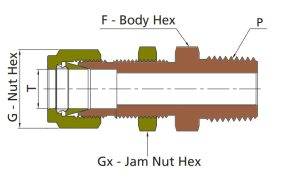

Bulkhead retainers digunakan sebagai pengganti kunci pas (wrench) terhadap body fitting segi-enam. Terdapat ukuran tubing dari 1/8 Inchi sampai dengan 1 Inchi dengan besar ukuran segi enam body Bulkhead Retainer sesuai dengan ukuran tersebut.

Retainer

Untuk memasang bulkhead fitting tanpa menggunakan retainer (penahan) diperlukan satu orang untuk memegang hex body fitting agar tidak berputar saat dikencangkan, sementara yang lain mengencangkan nut pengunci di sisi seberang panel dan fitting saat itu akan tertarik saat dikencangkan.

Dengan menggunakan penahan sekat (Retainer) kita hanya butuh satu orang saja dapat mengencangkan mur pengunci di sisi A untuk pemasangan sekat awal. Tubing sekarang dapat disambungkan ke sisi 1 atau 2 oleh satu orang dengan satu kunci karena penahan sekat (Retainer) berfungsi sebagai pengunci cadangan. Berikut dibawah ini adalah contoh installasi Bulkhead Connector.

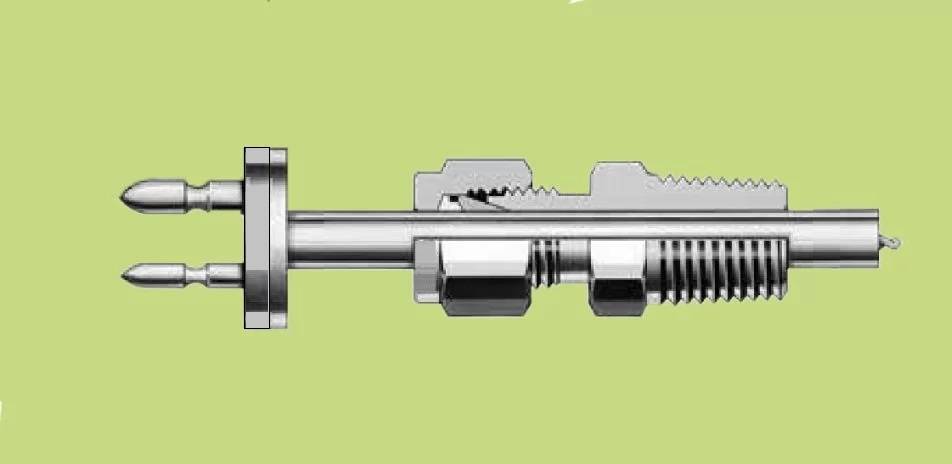

Male Connector tipe Thermocouple

Male connector jenis Thermocouple biasa juga disebut bored through male Connector atau bored through fittings. Thermocouple digunakan khusus untuk menghubungkan antar tubing bertekanan dan terdapat kabel di dalamnya dan dihubungkan dengan alat ukur, sebagai contoh thermal sensor. Termokopel tembus melalui male connector untuk mengakomodasi termokopel atau tabing didalam. Male Connector thermocouple yang dibor melalui reduksi dan tee standar dapat digunakan untuk membuat tee pada heat exchanger.

Bored through fittings mengalami penurunan kekuatan tekanan, sehingga kita perlu mengalikan Multiplied allowable working pressure dari tubing untuk mendapatkan tekanan kerja (working pressure).

Berbagai Jenis Ulir Male Connector

Konektor ini memiliki dua sisi sambungan yang berbeda dimana pada sisi pertama akan disambungkan dengan tubing dan sisi kedua akan disambungkan ke pipa dengan menggunakan ulir. Kita membutuhkan berbagai jenis ulir sesuai dengan aplikasinya seperti pada sambungan instalasi untuk kebutuhan hidrolik, instrument udara, gas dan kebutuhan lainnya.

Installasi Fitting menggunakan jenis ulir SAE atau MS Straight Paralel

Peralatan hidrolik sering kali menggunakan port ulir lurus berjenis SAE/MS sebagai pengganti ulir pipa. Port semacam itu memerlukan sambungan pipa yang menggunakan O-ring. Berbagai macam sambungan tubing, adaptor, dan reducer, tersedia dalam bahan stainless steel dengan jenis ulir lurus SAE/MS.

Konektor Male SAE/MS Sambungan pipa lurus memiliki O-ring yang langsung dimasukkan ke port lancip untuk membuat sealing (penyekat).

dibawah ini jenis male connector yang menggunakan jenia Ulir SAE

Mirip dengan ulir SAE, ulir metrik pada male connector juga memiliki cincin-O sebagai segel antara ulir fitting dan lubang port. Dan banyak ditemukan misalnya pada sistem hidrolik dan memiliki tipe ulir paralel.

berikut ini gambar Male connector yang memiliki ulir jenis Metric

Fitting dengan ISO Parallel Thread juga memiliki tipe ulir paralel, sedangkan sebagai seal menggunakan gasket atau tidak menggunakan O-ring.

Gasket menjadi seal antara fitting Thread.

berikut ini gambar Male connector jenis ulir Iso Pararlel.

JIC Thread have standard Unified SAE.

Jenis male connector type flaring atau disebut JIC memiliki kemiringan sebesar 37o dan ulir nya berjenias SAE, dibawah ini adalah gambar jenis male connector jenis Flaring atau JIC.

Tapered thread

Konektor ulir Tapered memiliki ulir NPT atau BSPT, aplikasi banyak digunakan dalam sistem instrumentasi atau saluran udara. NPT merupakan standar B1.20.1. Sealant Ulir Pipa harus selalu digunakan saat merakit male connector dan gitempatkan pada ulir Tapered (runcing/miring). Sealant ulir pipa anaerobik dan pita PTFE dapat digunakan untuk installasi. silahkan mengacu terhadap kekuatan sealant untuk mendeteksi Kebocoran, Pelumas, dan Sealant.

berikut ini adalah jenis sealent yang umum digunakan pada ulir Tapered yaitu jenis ulir NPT aatau BSPT.

Male connector type Welding

Sambungan ujung tipe pengelasan male connector harus memiliki proses produksi pemesinan yang berkualitas di semua port untuk memastikan pengelasan yang baik. pada Fitting welding dinyatakan bahwa tekanan kerja didasarkan pada ANSI/ ASME B31.3 pada suhu kamar, untuk menentukan tekanan kerja sesuai dengan ANSI/ASME B31.3 , kalikan tekanan kerja dengan koefisien faktor keamanan welding sebesar 0,94. terjadi penurunan kekuatan tekana tubing tersebut pada jenis koneksi welding.

Penggunaan welding fitting banyak diperuntukkan untuk proses sambungan pipa untuk steam panas, dikarenakan dibutuhkan keselamatan pekerja jika menggunakan tube fitting akan dapat di buka dengan mudah sehingga tidak aman. Ada beberapa jenis sambungan type las-las an, yaitu Socket weld, Buttweld. dibawah ini adalah gambar Male Connector jenia welding

Kami sebagai penyedia Tube fitting dapat memberikan informasi dan kebutuhan anda, silahkan Kontak kami.