Pneumatic Actuated Ball Valve Knowledge

Pneumatic Actuated Ball Valves is operation is use air (or other gas) and air pressure while use as the power source for pneumatic valve actuators, They use on linear or quarter turn valves. Air pressure acts on a piston or bellows diaphragm so creating linear force on a valve stem. With as Alternatively, a quarter turn vane type actuator is produces torque is to provide rotary motion to operate a quarter turn valve. Pneumatic actuated Ball Valve or pneumatic actuator may be arranged to be spring closed or spring open with air pressure following overcoming the spring to provide movement. Know is the type spring normally open or normally close is depend of your application function.

A “double acting” actuator is used air applied to different inlets with function, thus move the valve in the opening or closing of direction. A central compressed air system can provide with clean include dry compressed air needed for pneumatic actuators. Some types regulators for compressed gas here is as supply pressure and will provided from the process gas stream while waste gas either where is vented to air or dumped into lower pressure process piping. There is a basic mechanic of Pneumatic Ball Valve systems.

ACTUATION

Pneumatic Actuated Ball Valves are actuate manually or mechanically. Manual actuation is far the most common, and actuation is accomplished by rotary action with a screw thread stem, quarter turn rotary, or toggle lever.

Valves is operated frequently with located inconveniently and used a hazardous system fluid or integrated into an automated system usually is there require mechanical actuation. Mechanical actuators are operated by either pneumatic and electric power.

Most common Pneumatic Actuated Ball Valve and which are available in three types such as normally closed, normally open and double acting. Normally close in by a spring holds the valve either closed or open so pneumatic pressure moves the valve to the opposite position, and the valve is close position when normal condition. Normally open is valve is open when systems is normal condition. Double acting actuators is not have springs and it’s require pneumatic pressure to both open and close the valve. Pneumatic actuators may also include direct mounted and include solenoid valves. it’s have function with control by electrical signal from a control system sources from outside.

Features :

- Nomina Pipe Size is between 1/8~2 inchi with working pressure until 10,000 psig (690 bar) and temperature range is -65°F to 450°F (-54°C to 232°C) and

- Air supply pressure as low as 6 bar with low air consumption. Top indicator shows valve status and others interfaces that meet ISO 5211, NAMUR, and VDI/VDE 3845 standards.

- Explosion proof products with certification available.

NOTES:

Below is some Note about Actuation process :

① Air failure will cause the valve to stay at the position where the operation is disturb.

② Air failure will cause to the valve to return to the original normally open or closed state.

③ Air failure will cause to the valve to return to the original left end/right end normally open state.

Pneumatic Actuator Operating Conditions

- Air source

◎ dry and clean air. - Air supply pressure

◎ Recommended pressure: 6 bar.

◎ Maximum pressure: 8 bar. - Lubrication

◎ Factory lubricated for the life of actuator under normal working conditions - Installation

◎ The actuator can be install at any orientation indoors or outdoors.

◎ Temperature of 2 way ball valve pneumatic actuator : 5°F to 176°F (-15°C to 80°C) and 3- way ball valve pneumatic actuator: -40°F to 176°F (-40°C to 80°C)

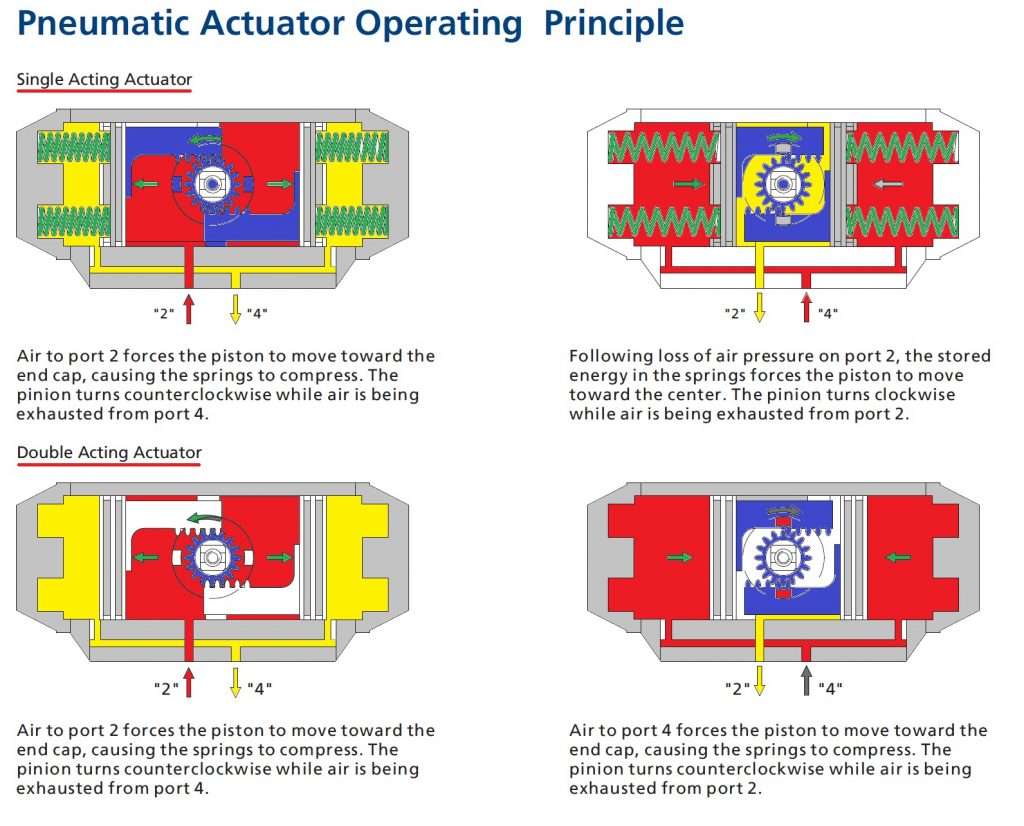

Pneumatic Actuator Operating Principle

Below is show how pneumatic actuator schema operation when pressure force to the spring to make move actuator so valve can open or closed.

Valve Operating Torque

Start (break) torque is the torque require to begin actuation of a valve and The actuator when start torque must be greater than the valve start torque. End (run) torque is the torque require to completed the actuation of valve. The actuator when end torque must be greater than the valve end torque.

Factors that Affect Operating Torque

Frequency of Use

Operating torque typically will increases as the time interval between cycles increases. For applications which valves are cycle less than frequently is can noted in the Calculating Operating systems.

Cycle Wear

Contacting surfaces ball valve, seat, and body. For example is gradually wear as valves are actuate repeatedly and resulting is increased friction and operating torque. Actuation speed may be influence for rate of valve wear as well.

Seat or Packing Material

In some ball valve designs have friction between ball and seat or packing, will affects operating torque which varies with material and lubricant.

System Pressure

Higher pressures cause greater contact forces and friction will resulting in higher operating torque.

System Temperature

Lower or higher temperatures is depending on the valve design and can cause increased operating torque require.

System Media

Different system fluids have varying viscosities, it’s while bringing about different levels of friction and affected operating torque. Some lightweight oils may be reduce operating torque. Fluid with Dirty, abrasive, or highly viscous fluids may cause increase operating torque.

If you need Improve your fluid systems with control pneumatic ball valve, we are PT. Solutec daya Mandiri is ready to serve you and include application to your fluid systems. Please Contact us.