Why Quick Couplers?

Quick couplers are easily overlook as simple, passive components, but they are an important part of a hydraulic system. A neglected quick coupler can easily become a point of failure.

Keep It Clean

Using contaminated (dirty) hydraulic fluid is the quickest way to shorten the life of a hydraulic system. One of the easiest ways to introduce contaminants is through the quick couplers.

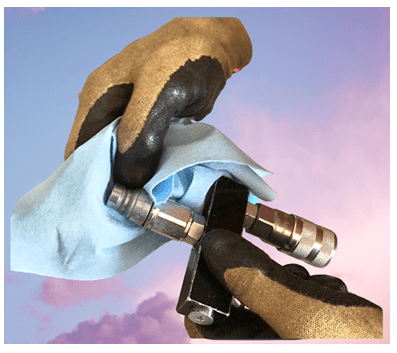

This is why the cap should be replace on a quick coupler whenever it is not in use.

More importantly, the quick coupler needs to be spray with lubricant, or wipe down with a clean cloth before it is connected.

The Internal

A quick coupler is basically two opposing check valves that have to mechanically unlock each other in order to enable flow.

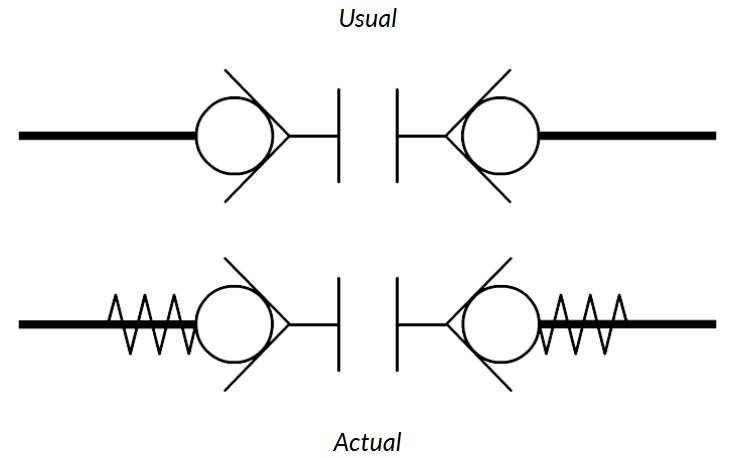

Schematic Symbol Quick Couplers

It should be noted that a schematic symbol of a quick coupler is rarely shown accurately.

Common Faults

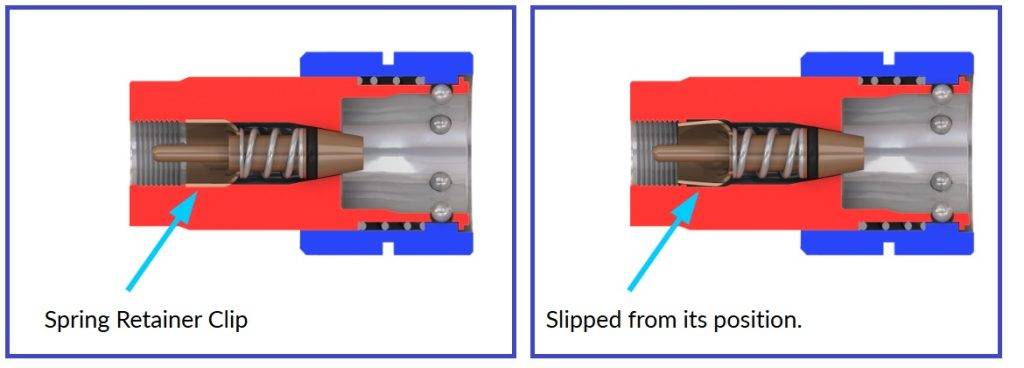

A typical fault is that the spring retainer clip slips out of its slot.

When this happens there is no longer enough spring tension to force open the check valve in the opposing half of the quick coupler. It may still allow flow in the opposite direction.

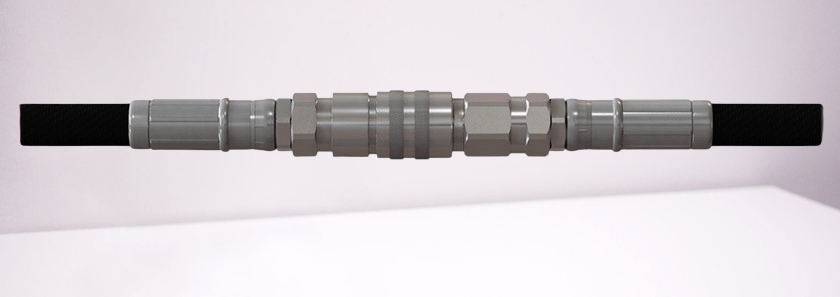

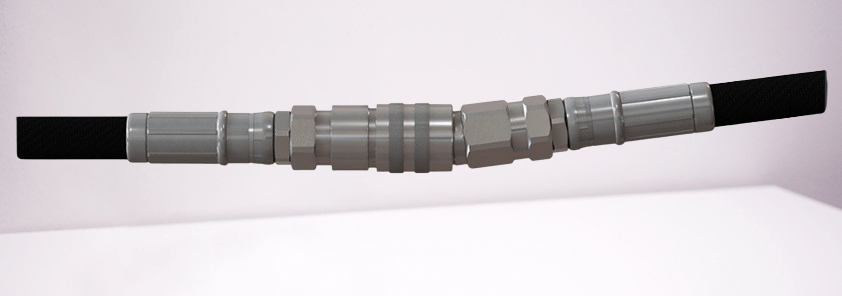

Another common fault Quick Couplers is that the two halves of the quick coupler may appear connected but are not. If they are slightly out of alignment, they will not fully connect.

Pay attention to the sleeve on the female half of an unconnected quick coupler. When it is properly connect, the sleeve will return to that position.

Contact

PT. SOLUTEC DAYA MANDIRI

- 02184901758

- 02184901759

- +6281219898239

- sales@solutecmandiri.com

-

Ruko Jatibening Park Blok B no 10B

Jl. Jatibening Raya (Ratna) Pondok Gede Bekasi Selatan 17412 Indonesia

Our service for industry are diverse and versatile as our customers requirements

Copyright © 2025 PT. Solutec Daya Mandiri (SDM). All rights reserved.

Contact

PT. SOLUTEC DAYA MANDIRI

- 02184901758

- 02184901759

- +6281219898239

- sales@solutecmandiri.com

-

Ruko Jatibening Park Blok B no 10B

Jl. Jatibening Raya (Ratna) Pondok Gede Bekasi Selatan 17412 Indonesia

Our service for industry are diverse and versatile as our customers requirements

Copyright © 2025 PT. Solutec Daya Mandiri (SDM). All rights reserved.