Relief Valve

- What is Direct Acting Relief Valve

- How It Works

What Is a Direct Acting Relief Valve?

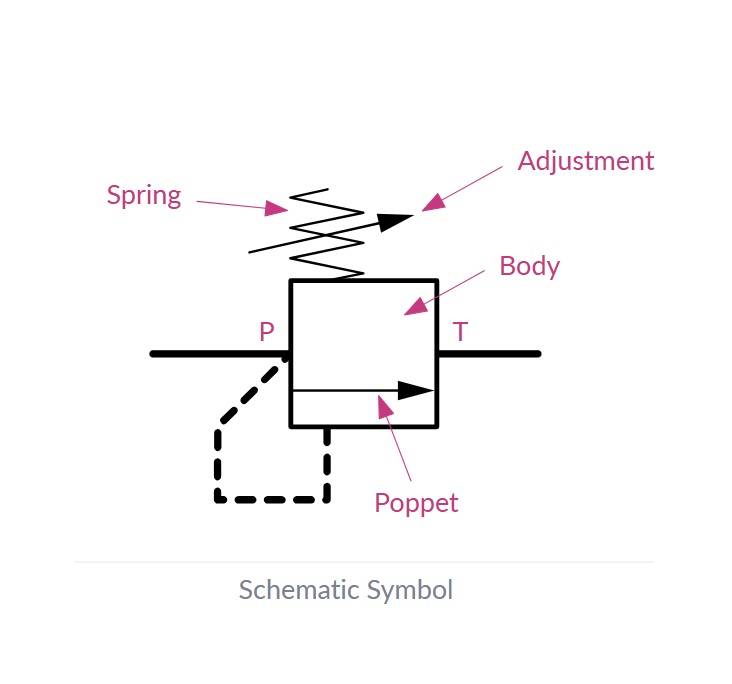

A direct acting relief valve is the most basic of the pressure controls, consisting of only one poppet and one spring. It is used to limit maximum system pressure.

The advantages of a direct acting style of relief valve are that it is:

- inexpensive

- fast-acting

- simple

This valve is good for controlling sudden, momentary pressure spikes. It can also be used as a pilot control for other valves.

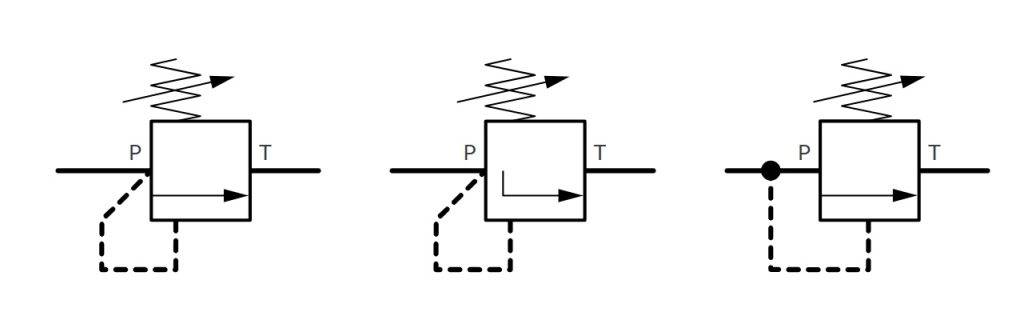

Below are some variations of the schematic symbol for a direct acting relief valve. The P label is the inlet port from the pump and the Label is the port that leads back to tank.

How Relief Valve Work

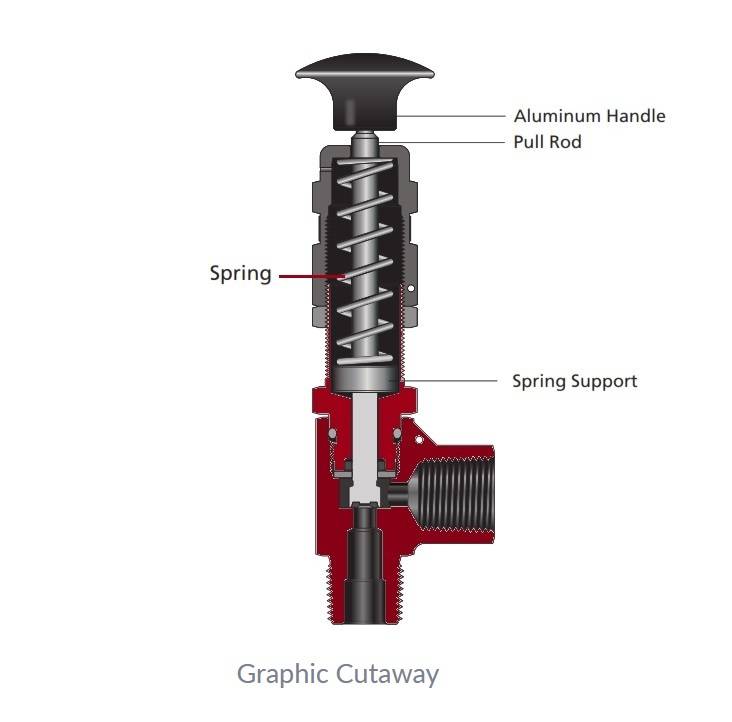

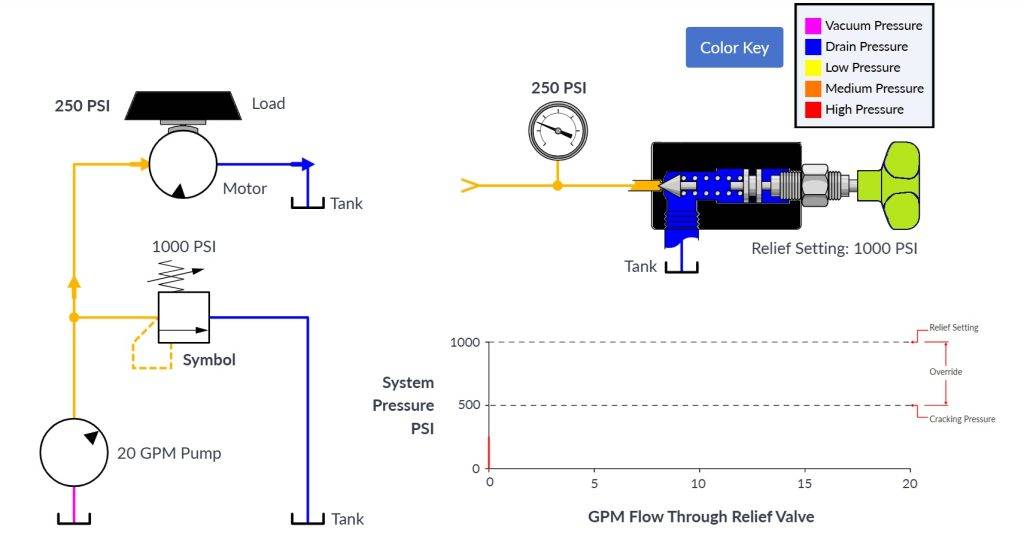

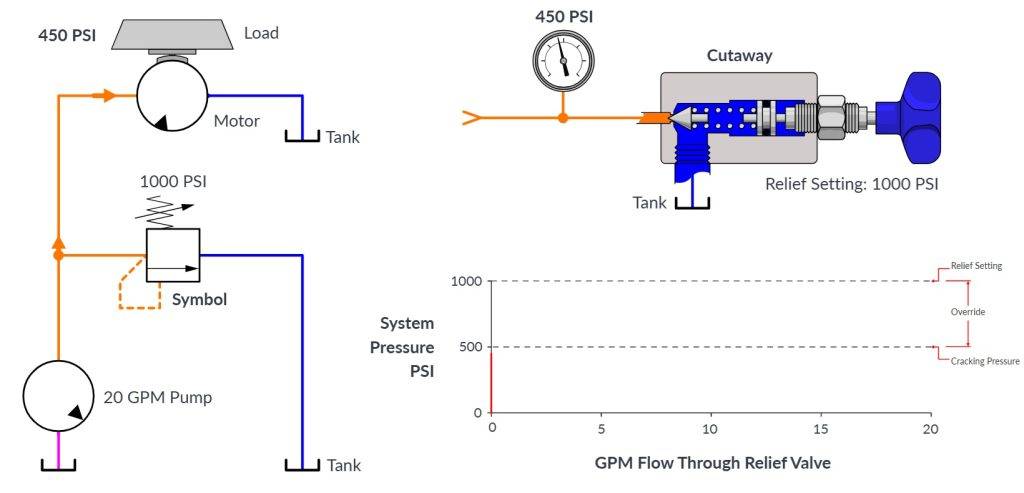

Here is a direct acting relief valve shown in schematic form and as a graphic cutaway.

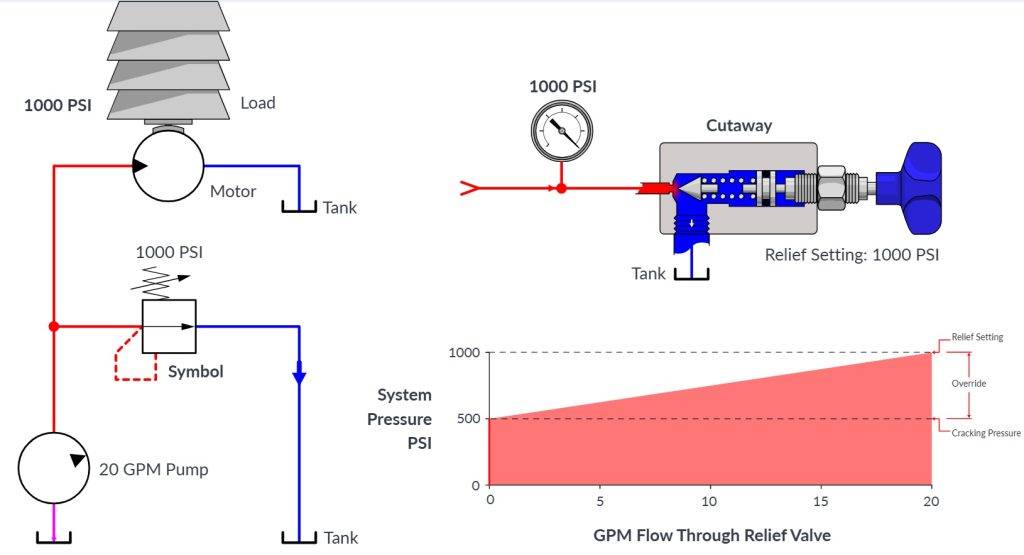

The relief pressure is set to 1000 psi and the system pressure is currently at 250 psi, so the relief valve remains closed.

“Relief Pressure is the maximum system pressure that will occur under normal operating conditions and with all of the pump’s flow passing through the relief valve”

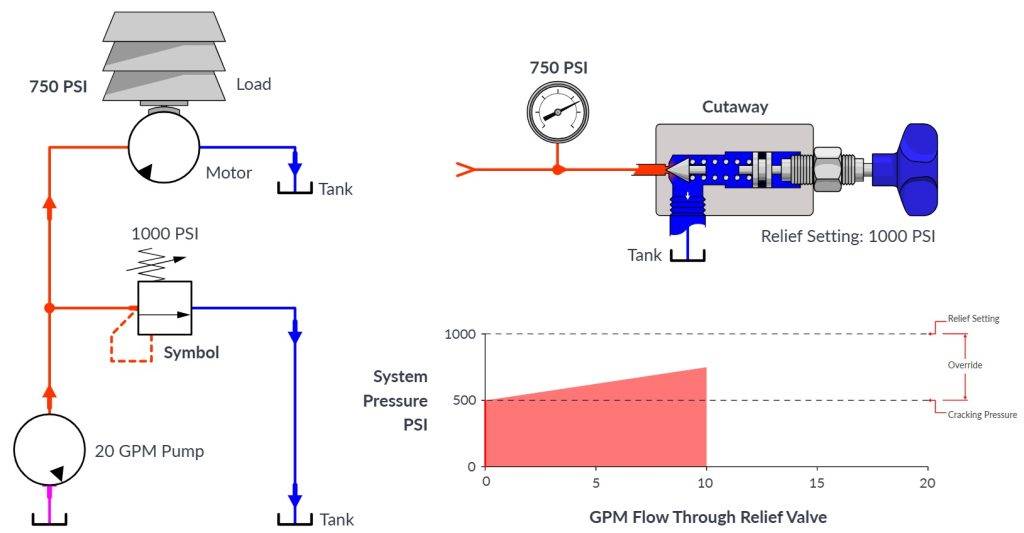

As the load is increased on the motor and the pressure increases, which causes the relief valve to open slightly. This is because the cracking pressure on this relief valve is 500 psi below the current setting pressure.

As the load is increased on the motor and the pressure increases, which causes the relief valve to open slightly. This is because the cracking pressure on this relief valve is 500 psi below the current setting pressure.

As system pressure approaches the relief setting so the valve opens part-way and divides flow. The motor will slow down as a result.

As the system pressure increases from the initial cracking pressure towards the pressure setting, the relief valve will open more and more. Once the relief pressure setting is reached, the relief valve will be fully open, and diverting all the pump’s flow back to the tank. The motor will now be stopped.

Now, as soon as system pressure falls below the pressure needed to open it, the relief valve closes again.

Proportional Relief Valve

RV, RL and RM Series.

◎ Set pressure:

RV series : 7 color coded springs available for a wide range of set pressure, 50 to 6000 psig @ 70°F (3.4 to 414 bar @ 20°C)

RL series:0 to 225 psig @ 70°F (0.68 to 15.5 bar @ 20°C)

RM series : 3 color-coded springs available for a wide range of set pressure, 50 to 1500 psig @ 70°F (3.4 to 103 bar @ 20°C)

◎ Maximum outlet pressure :

RV series : 1500 psig (103 bar)

RL series : 225 psig (15.5 bar)

RM series : 1500 psig (103 bar)

◎ Working temperature: -10°F to 300°F (-23°C to 148°C)

◎ Liquid or gas service

◎ Adjustable bonnet cap and adjustable set pressure

◎ Lead seal through lock wire holes to lock proportional relief valve therefore to secure a set pressure effectively

◎ Variety of seal materials

◎ Label identifies the set pressure range

Set Pressure and Resealing Pressure Relief Valve

Set pressure : The set pressure is the upstream pressure at which the first indication of flow occurs. The repeatability of set pressure of each valve after initial relief is ±5% while room temperature.

Resealing pressure : The resealing pressure is the upstream pressure at which there is no indication of flow. Resealing pressure is always lower than set pressure.

Applications

Relief valves are proportional valves that open gradually as the pressure increases. Consequently, they do not have a capacity rating at a given pressure rise (accumulation), and they are not certified to ASME or any other codes.

Some system applications require valves to meet specific safety codes. The system designer and user must determine when such codes apply and whether these valves conform to them.

FITOK proportional relief valves should never be used as ASME Boiler and Pressure Vessel Code safety relief devices.

FITOK proportional relief valves are not “Safety Accessories” as defined in the Pressure Equipment Directive

2014/68/EU.