Pendahuluan tentang Seamless Tubing

Karakteristik Seamless Tubing berbeda-beda sesuai dengan aplikasinya. Karakteristik ditentukan oleh masing-masing aplikasi pada standar internasional. Spesifikasi Seamless Tubing telah ditentukan oleh ASTM, ASME dan standar internasional lainnya.

Seamless Tubing memiliki ketebalan (thickness) yang homogen tanpa ada nya pengelasan (welding) atau sambungan sepanjang tubing tersebut dan memiliki permukaan yang halus. Permukaan bagian dalam tubing tidak mengalami pengurangan kekuatan yang disebabkan oleh internal pengelasan (welding) dan perbedaan struktur komposisi kimia serta struktur mikro yang berbeda pada area pengelasan. Dengan demikian, tidak ada bahaya korosi yang disebabkan akibat korosi galvanik (galvanic corrosion) yang ditimbulkan sendiri. Hal ini membuat Seamless tubing menjadi pilihan utama di mana kekuatan terhadap tekanan dan ketahanan terhadap korosi menjadi faktor yang sangat diutamakan. Penggunaan akhir Seamless tubing sangat beragam, dengan mempertimbangkan sifat-sifat tubing tersebut dan dengan memiliki sifat tanpa sambungan sehingga banyak pengguna akhir secara luas di dalam industri.

Seamless vs Welded Tubing

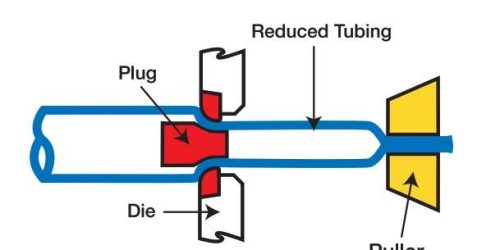

Kita telah memahami bahwa pemilihan antara seamless tubing atau welded tubing adalah sangat berbeda sehingga harus memenuhi beberapa syarat. Perbedaannya terletak pada cara dasar pembuatannya yang terlihat jelas dari penamaannya. Seamless Tubing dibentuk dari diekstrusi (extruded) dan ditarik (drawn) tetapi welded tubing diproduksi dari strip yang dibentuk gulungan dan dilas untuk menghasilkan tubing bulat. Welded Tubing jauh lebih murah daripada Seamless Tubing dan tersedia dalam ukuran panjang juga tetapi kekuatan tekanan kerja (working pressure) welded tubing adalah 20% lebih rendah daripada Seamless tubing.

Persyaratan Kualitas seamless Tubing dan Welded tubing

Saat membuat pemilihan ini, persyaratan kualitas, seperti korosi, batasan dimensi, dan kekuatan, harus menjadi kriteria utama. Seringkali, perusahaan memilih tubing atau pipa berdasarkan proses manufaktur, yang dapat menyebabkan kesalahan representasi kebutuhan seseorang dan akibatnya pilihan opsi tubing yang kurang hemat biaya atau tidak tepat. Daftar di bawah ini menyajikan kualitas paling umum yang penting untuk berbagai aplikasi dan juga menyarankan jenis produk mana yang paling sesuai dengan kebutuhan aplikasi.dalam menentukan tubing yang ideal

- Toleransi OD (diameter luar)

- Toleransi Tebal dinding tubing (thickness)

- Konsekuensi ekstrim dari kebocoran setelah fabrikasi

- Korosi akibat keadaan lembab/basah : General, Pitting, Stress Corrosion Cracking (SCC), Microbial Induced Corrosion (MIC)

- Suhu Tinggi: Pengoksidasi, Sulfidasi, Karburisasi, Debu Logam

- Kebersihan : tubing dengan kemurnian tinggi dan kemurnian ultra tinggi dirancang khusus untuk industri dengan aplikasi higienis, seperti Farmasi, Biofarmasi, serta Makanan dan Minuman.

Seamless Tubing memiliki ketebalan (thickness) yang homogen tanpa ada nya pengelasan (welding) atau sambungan sepanjang tubing tersebut dan memiliki permukaan yang halus. Permukaan bagian dalam tubing tidak mengalami pengurangan kekuatan yang disebabkan oleh internal pengelasan (welding), perbedaan struktur komposisi kimia serta struktur mikro yang berbeda pada area pengelasan. Dengan demikian, tidak ada bahaya korosi yang disebabkan akibat korosi galvanik (galvanic corrosion) yang ditimbulkan sendiri. Hal ini membuat Seamless tubing menjadi pilihan utama di mana kekuatan terhadap tekanan dan ketahanan terhadap korosi menjadi faktor yang sangat diutamakan. Penggunaan akhir Seamless tubing sangat beragam, dengan mempertimbangkan sifat-sifat tubing tersebut dan dengan memiliki sifat tanpa sambungan sehingga banyak pengguna akhir secara luas di dalam industri.

Evaluasi Kondisi Proses

Pemilihan tubing welding, welding drawn, atau seamless tidak akan lengkap tanpa mengevaluasi kondisi proses untuk risiko kebocoran. Pertimbangan harus diberikan pada kemungkinan korosi serta potensi bahaya apa pun, karena faktor-faktor ini akan mempengaruhi pemilihan jenis tubing, jumlah pemeriksaan non-destruktif (NDE), dan kebutuhan untuk evaluasi korosi. Terkadang, proses pemilihan antara Welded, Welded & Drawn, dan Seamless yubing bisa terasa sulit. agar sesuai dengan persyaratan kualitas spesifik.

Gas Services

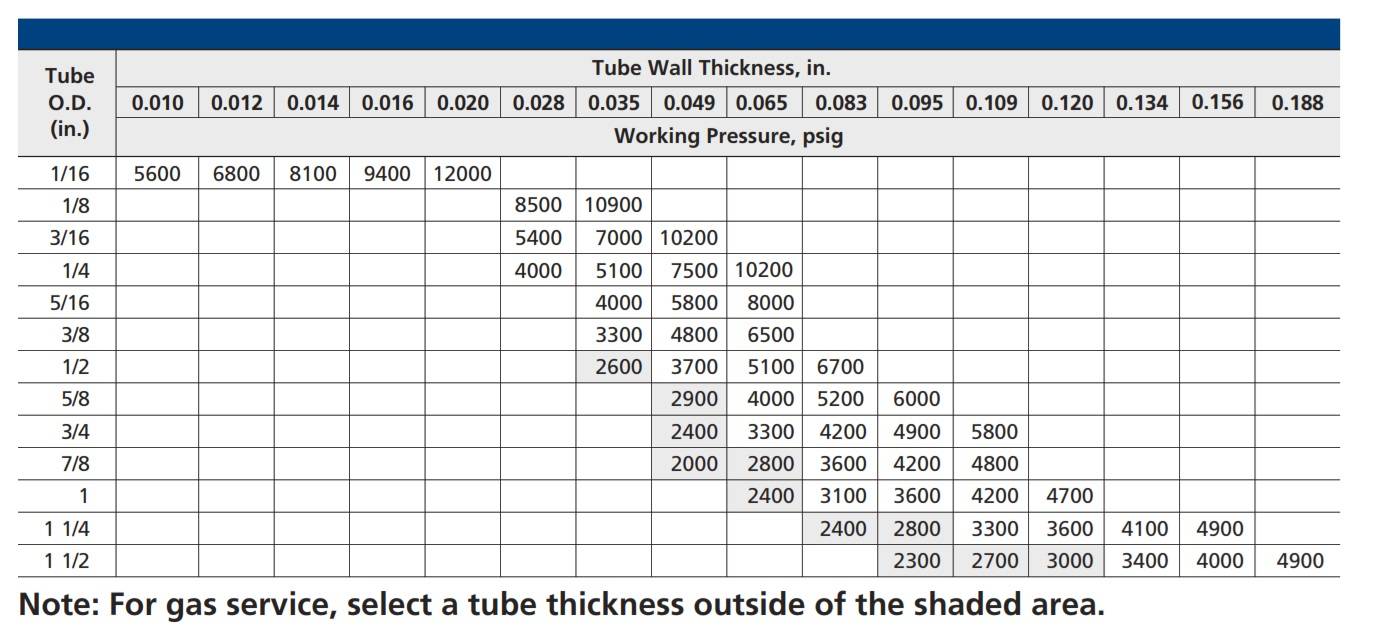

Gas udara, hidrogen, helium, nitrogen, dll.) memiliki molekul yang sangat kecil yang dapat lolos bahkan melalui jalur kebocoran paling kecil sekalipun. Beberapa cacat permukaan pada Tubing dapat memberikan jalur kebocoran. Saat diameter luar tabung (OD) meningkat, demikian pula kemungkinan goresan atau kerusakan permukaan lainnya yang mengganggu penyegelan (sealing) yang tepat. Sambungan yang paling berhasil untuk layanan gas akan terjadi jika semua petunjuk pemasangan diikuti dengan cermat dan ketebalan dinding pipa yang lebih tebal pada tabel yang sudah ditentukan seperti dibawah ini.

Catatan: Untuk Gas Servis, pilih ketebalan tubing di luar area yang diarsir.

Ketebalan Dinding Tubing (Wall thickness)

Tabel yang menyertainya menunjukkan peringkat tekanan kerja welded tubing dan Seamless Tubing dalam berbagai ketebalan dinding. Kecuali sebagai catatan, peringkat tekanan yang diizinkan dihitung dari nilai S seperti yang ditentukan oleh ASME B31. 3,. Fitting tubing FITOK telah berulang kali diuji pada ketebalan dinding minimum dan maksimum yang ditunjukkan. Fitting tubing FITOK tidak direkomendasikan untuk ketebalan dinding tabung di luar kisaran yang ditunjukkan pada tabel di atas untuk setiap ukuran.

Jika anda ingin mengetahui secara luas tentang Seamless tubing silahkan klik produk kami berikut ini.