Stainless Steel Needle Valves

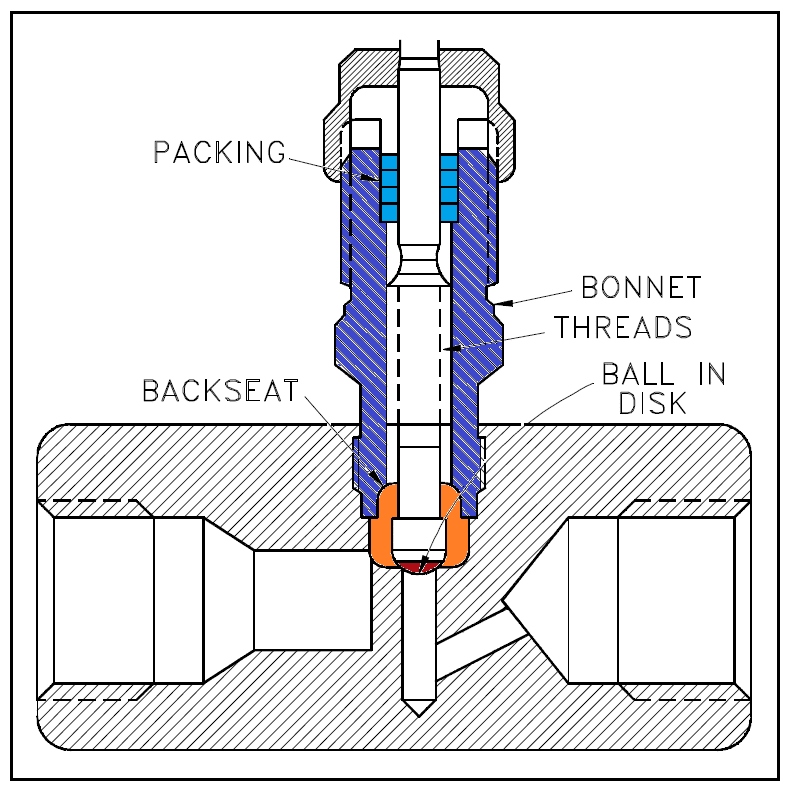

A Stainless Steel needle valve, as shown in Figure 1, is used to make relatively fine adjustments in the amount of fluid flow. The distinguishing characteristic of a needle valve is the long, tapered, needle like point on the end of the valve stem. This “needle” acts as a disk.

The longer part of the needle is smaller than the orifice in the valve seat and passes through the orifice before the needle seats. This arrangement permits a very gradual increase or decrease in the size of the opening. Needle valves are often used as component parts of other, more complicated valves. For example they are used in some types of reducing valves.

Needle Valve Applications

Most constant pressure pump governors have Stainless Steel needle valve to minimize the effects of fluctuations in pump discharge pressure. Needle valves are also used in some components of automatic combustion control systems where very precise flow regulation is necessary.

Needle Valve Body Designs

One type of body design for a Stainless Steel needle valve is the bar stock body. Bar stock bodies are common and in globe types, and ball swiveling in the stem provides the necessary rotation for seating without damage. The bar stock body is illustrated in Figure 2.

Needle valve are frequently used as metering valves. Metering valves are used for extremely fine flow control. The thin disk or orifice allows for linear flow characteristics. Therefore, number of hand wheel turns can be directly correlated to the amount of flow. A typical metering valve has a stem with 40 threads per inch.

Needle valves generally use one of two styles of stem packing: an O-ring with TFE backing rings or a TFE packing cylinder. Needle valves are often equipped with replaceable seats for ease of maintenance.

Valve Bonnet

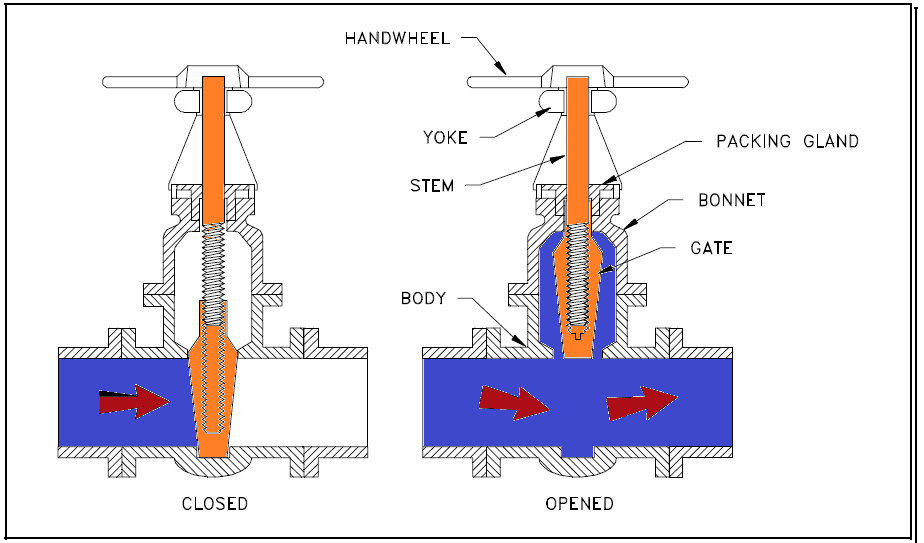

The cover for the opening in the valve body is the bonnet. In some designs, the body itself is split into two sections that bolt together. Like valve bodies, bonnets vary in design. Some bonnets function simply as valve covers, while others support valve internals and accessories such as the stem, disk, and actuator.

The bonnet is the second principal pressure boundary of a valve. It is cast or forged of the same material as the body and is connected to the body by a threaded, bolted, or welded joint. In all cases, the attachment of the bonnet to the body is consider a pressure boundary. This means that the weld joint or bolts that connect the bonnet to the body are pressure-retaining parts.

Valve bonnets, although a necessity for most valves, represent a cause for concern. Bonnets can complicate the manufacture of valves, increase valve size, represent a significant cost portion of valve cost, and are a source for potential leakage.

Stem

The stem, which connects the actuator and disk, is responsible for positioning the disk. Stems are typically forged and connected to the disk by thread or weld joints. For valve designs requiring stem packing or sealing to prevent leakage, a fine surface finish of the stem in the area of the seal is necessary. Typically, a stem is not consider a pressure boundary part.

Connection of the disk to the stem can allow some rocking or rotation to ease the positioning of the disk on the seat. Alternately, the stem may be flexible enough to let the disk position itself against the seat. However, constant fluttering or rotation of a flexible or loosely connected disk can destroy the disk or its connection to the stem.

Two types of valve stems are rising stems and non rising stems. Illustrated in Figures 3 and 4, these two types of stems are easily distinguish by observation. For a rising stem valve, the stem will rise above the actuator as the valve is open. This occurs because the stem is thread and mated with the bushing threads of a yoke that is an integral part of, or is mount to the bonnet.

There is no upward stem movement from outside the valve for a non rising stem design. For the non rising stem design, the valve disk is thread internally and mates with the stem threads.

Valve Packing

Most valves use some form of packing to prevent leakage from the space between the stem and the bonnet. Packing is commonly a fibrous material (such as flax) or another compound (such as teflon ) that forms a seal between the internal parts of a valve and the outside where the stem extends through the body. Valve packing must be properly compress to prevent fluid loss and damage to the valve’s stem. If a valve’s packing is too loose, the valve will leak, which is a safety hazard. If the packing is too tight, it will impair the movement and possibly damage the stem.

Please free contact us if need some tyep of needle valve.