Union Tube Fittings

Pengenalan Union Tube

Union Tube banyak digunakan sebagai fitting penyambung untuk tubing, dalam banyak kasus instrumentasi tubing lurus(straight) menggunakan panjang maksimal 6 meter atau 20 kaki. Selain itu tubing lurus(straight) juga tersedia tubing dalam bentuk Gulungan (coil) dengan panjang yang bervariasi sesuai keinginan.

Coil Tubing

Straight Tubing

Union tube digunakan untuk menghubungkan tubing seamless atau tubing welded dan tidak digunakan untuk pipa atau sambungan lainnya.

Kami menyediakan jenis jenis fitting jika perlu memasang instrumen atau sistem hidrolik yang dibutuhkan, dan berikut ini adalah gambar union tube berbahan stainless steel.

Union Tube

Jenis-jenis Union Tube

Fitting jenis ini memiliki berbagai bentuk dan variasi ukuran, dan berikut ini adalah informasi mengenai bentuk-bentuk tersebut sebagai berikut:

Union Tube

Telah dijelaskan sebelumnya bahwa fitting ini digunakan untuk menghubungkan tubing dengan jenis dan ukuran yang sama. baik pada sisi kiri dan kanan ukurannya sama persis dan bentuknya juga sama persis.

Conversion Union

Disebutkan sebagai Conversion karena digunakan untuk menghubungkan dua jenis koneksi yang berbeda. Penggunaan yaitu untuk koneksi berbagai jenis unit pengukuran, seperti penghubung antara standar Fractional dan standar Metrik.

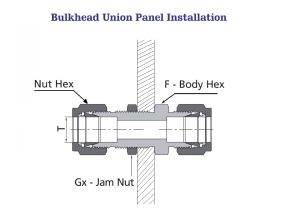

Bulkhead Union Tube

Bullhead union digunakan untuk panel, pada salah satu sisi fitting terdapat Nut (mur) tambahan yang berfungsi sebagai pengikat terhadap lubang panel. Di samping ini kami berikan gambar penggunaan bulhead union tube pada panel.

Bulkhead Reducing Union

Bulkhead Reducing Union adalah pereduksi dengan adanya Nut pengencang yang digunakan untuk menyambung tubing dengan berbagai macam ukuran, yaitu ukuran besar menuju ukuran lebih kecil dan digunakan pada lubang panel juga.

Bulkhead Conversion Union

Bulkhead Conversion union juga digunakan untuk menghubungkan dua jenis koneksi. Penggunaan koneksi adalah berbagai jenis unit pengukuran, seperti ukuran fractional ke Metrik atau sebaliknya dan digunakan dalam lubang panel.

Bulkhead Lock Nut

Nut (Mur) Pengunci Sekat adalah Nut (mur) yang digunakan sebagai pengunci dan pengencang pada lubang panel.

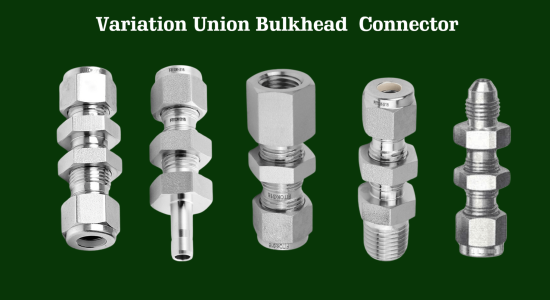

Other Type Bulkhead Union

Berikut ini adalah beberapa bentuk gambar Bulkhead Connector.

Campuran (intermixing) dengan Spesifikasi ukuran yang Berbeda

Mencampur komponen dengan spesifikasi berbeda dalam union tube dapat membahayakan kinerja seal tube fitting. Karena perbedaan ukuran, kinerja seal dapat berkurang secara signifikan setelah pemasangan. Beberapa ukuran metrik dan fractional sangat mirip, seperti ferrules 6mm dan 1/4″, sehingga sulit dibedakan jika dicampur menjadi satu. Oleh karena itu, fitting dengan spesifikasi berbeda harus disimpan secara terpisah. Selain itu, selama pemasangan, penting untuk memeriksa dengan cermat apakah spesifikasinya sudah benar untuk menghindari masalah yang disebutkan di atas.

FITOK telah merancang dengan memberikan tanda (step) marking pada body fitting dan Nut pada tube fitting untuk fitting ukuran metrik untuk membedakannya secara visual dari spesifikasi pecahan. Komponen tempa seperti elbow, tee, dan cross tidak memiliki step pada bodinya tetapi ditandai dengan ukuran metrik pada portnya.

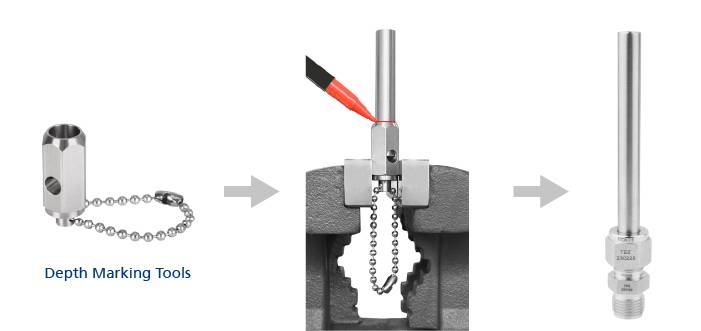

Installasi

Metode Pemasangan Union Tube sama dengan fitting tube lainnya seperti yang dijelaskan pada link berikut.

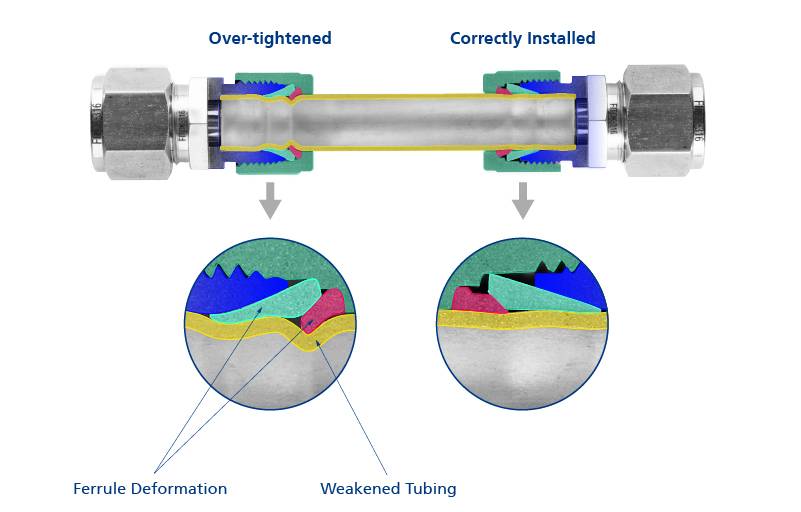

Pengencangan yang Kurang atau Pengencangan yang Berlebihan dalam Pemasangan Fitting

Pemasangan Union Tube kurang kencang dapat mencegah sealing yang tepat antara ferrule dan tubing, yang berpotensi menyebabkan kebocoran sedang selama pengoperasian sistem. Saat memasang tube fitting pada awalnya, alat pengukur celah dapat digunakan untuk menentukan apakah fitting cukup dikencangkan, membantu menghindari kebocoran yang disebabkan oleh pemasangan yang longgar.

Mengencangkan Nut secara berlebihan dapat menyebabkan deformasi pada ferrule dan tube, meningkatkan risiko kebocoran. Fitting dan tubing yang cacat atau rusak akan memerlukan perbaikan atau penggantian, yang mengakibatkan biaya tambahan. Selain itu, pengencangan yang berlebihan dapat mengurangi berapa kali pemasangan dapat dipasang kembali.

Alat pengukur Celah

Kami menyediakan berbagai jenis dari Tube Fittings dan juga alat untuk pembengkok (bending) Tube installation Tools.