One-piece Instrumentation Ball Valves BO Series

Features

◎ Working pressure up to: 3000 psig (207 bar)

◎ Working temperature: -65°F to 300°F (-54°C to 148°C)

◎ End connections:

1/4 to 1/2 thread

1/16″ to 3/4″ and 3 mm to 18 mm tube fitting

◎ 2-, 3-, 4-, 5-, 6- and 7-way models for on-off, switching and crossover service available

◎ One-piece body and one-piece ball stem

◎ No dead space

◎ Top-loaded design to allow adjustment with the valve in-line

◎ Thermal cycle performance improved, and wear compensated by live-loaded design

◎ Any reasonable connections available

◎ Pneumatic and electric actuator available

◎ Handle color options available

◎ Full operating pressure at any port

◎ Leak-tight performance testing with nitrogen or compressed air for every valve at the rated pressure to meet the requirement of no visible leak

◎ The inlet can be any port except for valves with vent ports

PFA, UHMWPE Packing Seat

The working temperature of UHMWPE packing seat should not be higher than 150°F (65°C).

Application : CNG-Powered Vehicle (NGV) and Fueling System Solutions

Note:

1. To prevent seat leakage, packing adjustment may be required periodically during the service life of the valve.

2. A higher initial actuation torque may happen to the valves that have not been cycled for a period of time.

3. Before installation, instrumentation ball valves exposed to dynamic temperature conditions may lose their initial packing load. Stem packing adjustment should be required.

Cleaning and Packaging:

FC-01: Standard cleaning and packaging for general industrial procedures.

FC-02: Special cleaning and packaging for wetted system components to ensure compliance with product cleaning requirement of ASTM G93 Level C

◎ SilcoNert 2000 (Sulfinert) Coating: Wetted metal components SilcoNert 2000 (Sulfinert) coated.

Vent Port Options

The maximum working pressure for vented valves is 500 psig (34.4 bar).

Straight-pattern Valves

A vent hole in the side of the valve body makes the downstream port vent to atmosphere when the valve is closed.

Angle-pattern and 3-way Valves

A vent hole in the side of the valve body makes the bottom port vent to atmosphere when the valve is closed.

Welded Vent Port Connections

A FITOK tube fitting or a tube stub welded to the vent port is available for stainless steel vented valves.

Locking Device 1 can lock BO series valves with 90° or 180° rotation handle, locking hole diameter is 0.21 in (5.2 mm);

To order a ball valve with locking device 1, add -LH to the valve ordering number.

Example: BOSS-FL6-07-LH/BOSS-FL6-07-3L-LH

Locking Device 2 can lock BO series valves with 90°,180°, or 360° rotation handle, locking hole diameter is 0.34 in (8.7 mm);

To order a ball valve with locking device 2, add -LK to the valve ordering number.

Example: BOSS-ML6-05-LK/BOSS-ML6-05-5L-LK

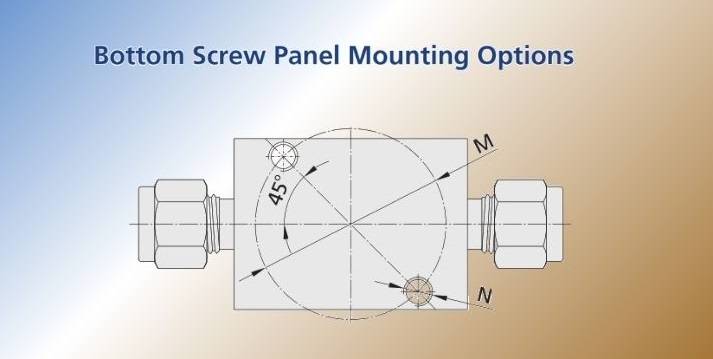

Bottom Screw Panel Mounting Options

Mounting Dimensions

The are not available on angle-pattern valves, 3-way valves, 6-way valves and 7-way valves bottom screw panel mounting options.

Ball Valve Component Animation for one piece Body