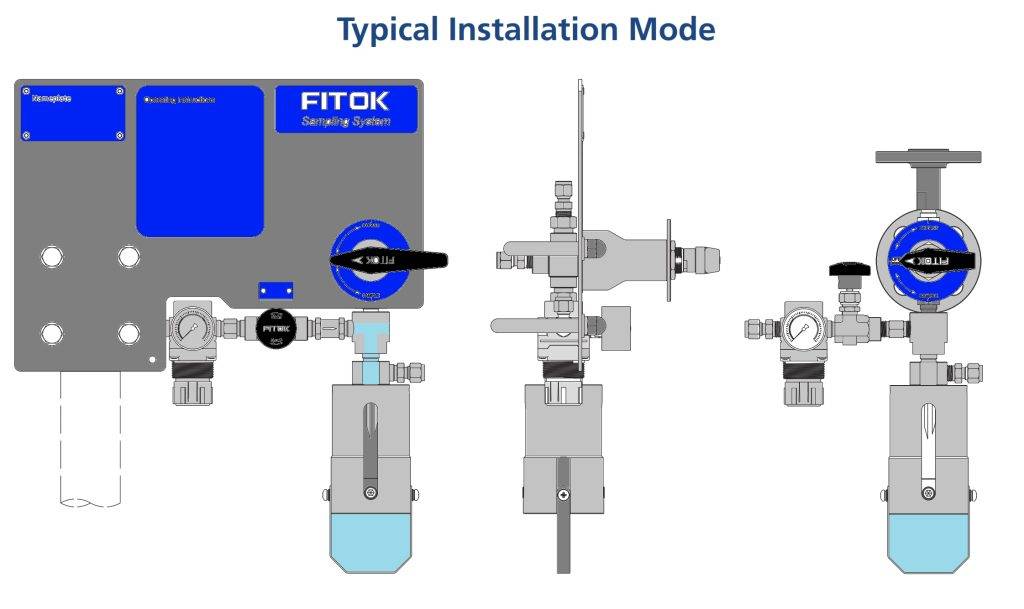

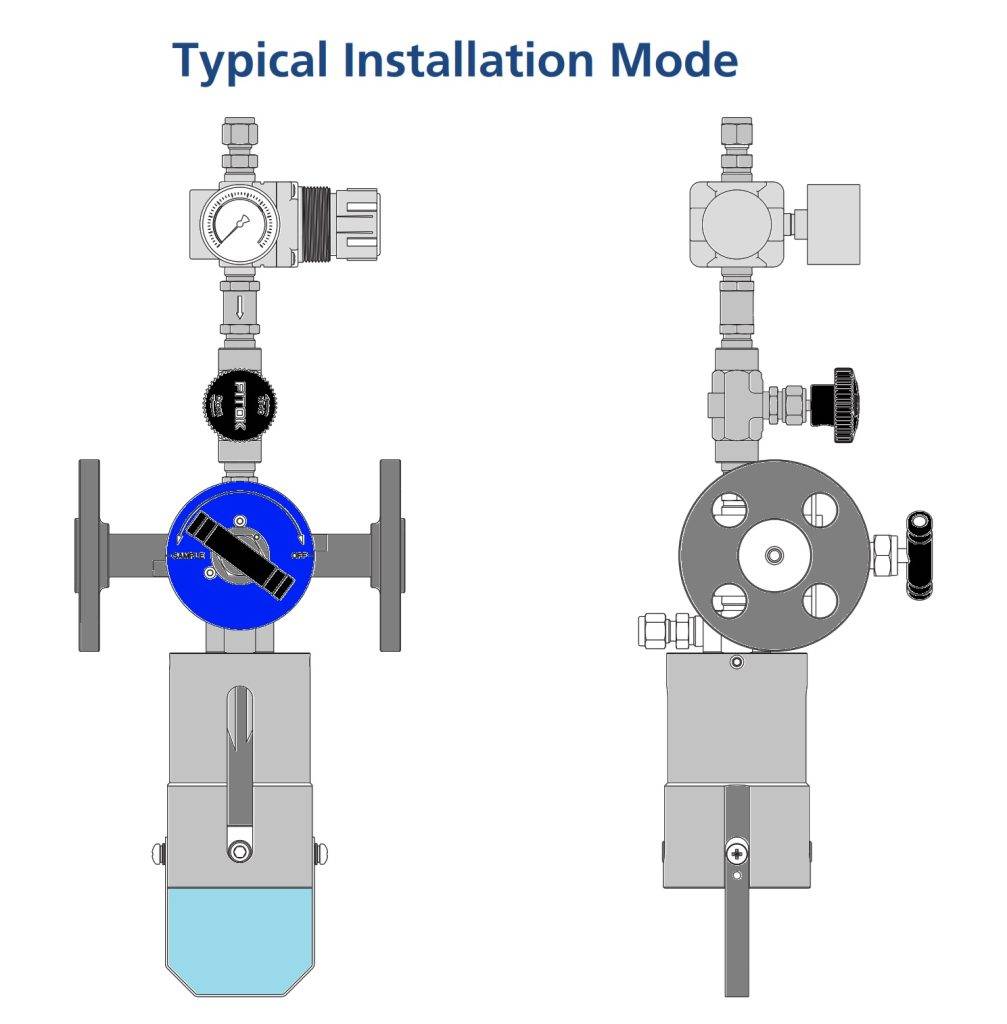

Liquid Sampling Systems : BLA Series-Bottle Configuration

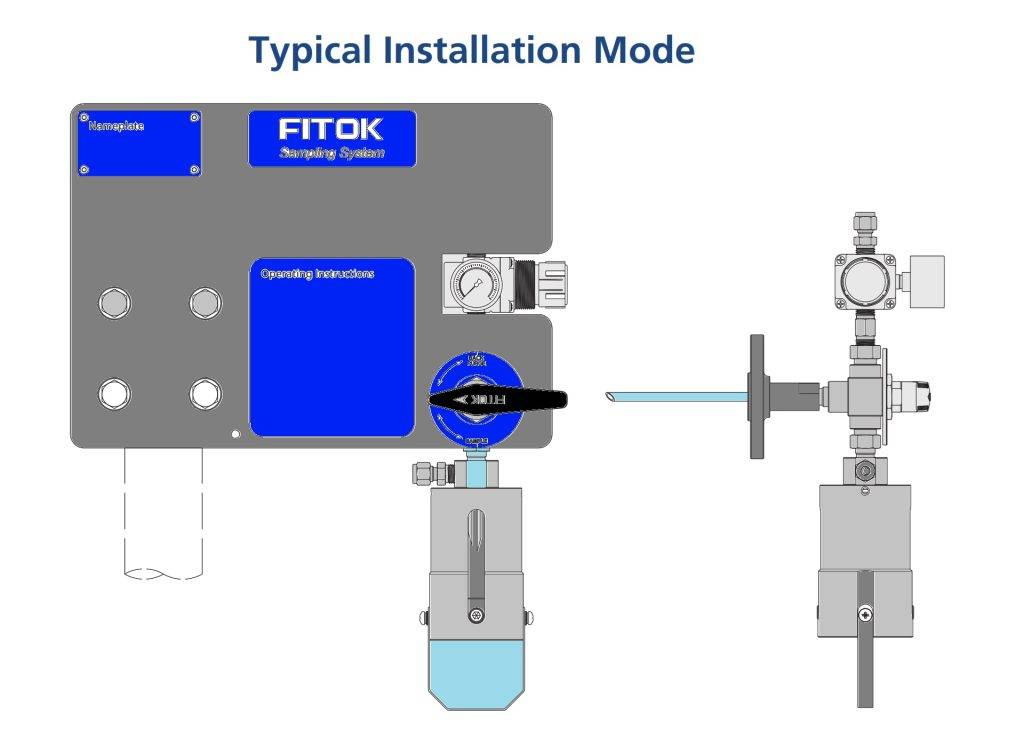

Liquid sampling system, with needle purge, the needle assembly and sampling bottle are purged by an inert gas before or after sampling, ensuring a clean needle and a representative sample, Max. operating pressure of 145psi (10bar), one handle operation.

BLA Series

Introduction:

Sampling systems for low vapor pressure liquid at low process pressure equipping with three-way ball valves or in-line needle valves.

Features:

© Representative liquid sampling for corrosive or hazardous liquids of low vapor pressure (<0.7 bar)

© Sampling from low pressure devices or process lines: 0-145 psi (0-10bar)

© Various different designs of Nitrogen purge

© 7 models available

A Series

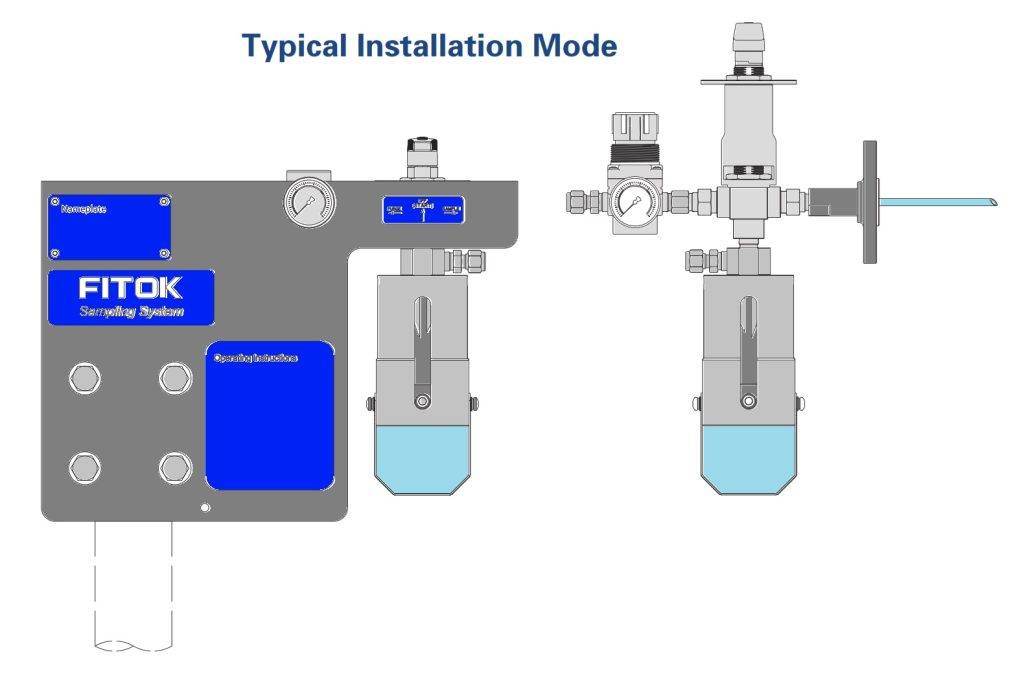

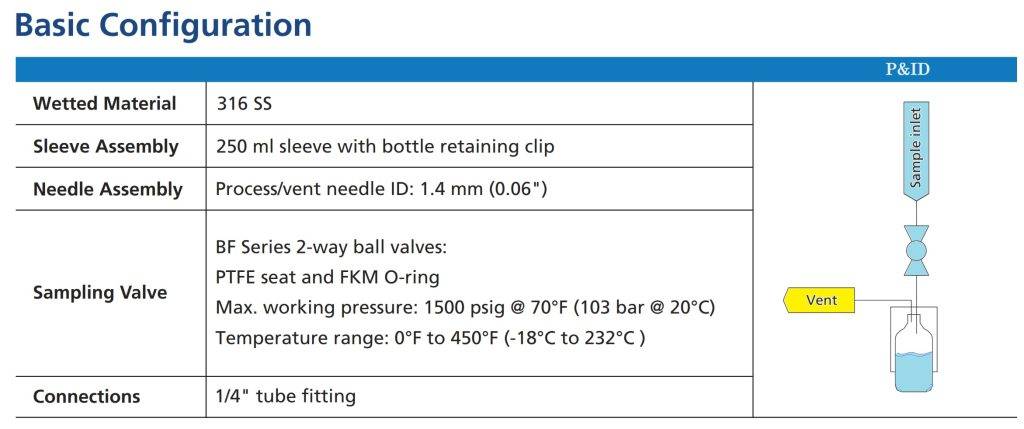

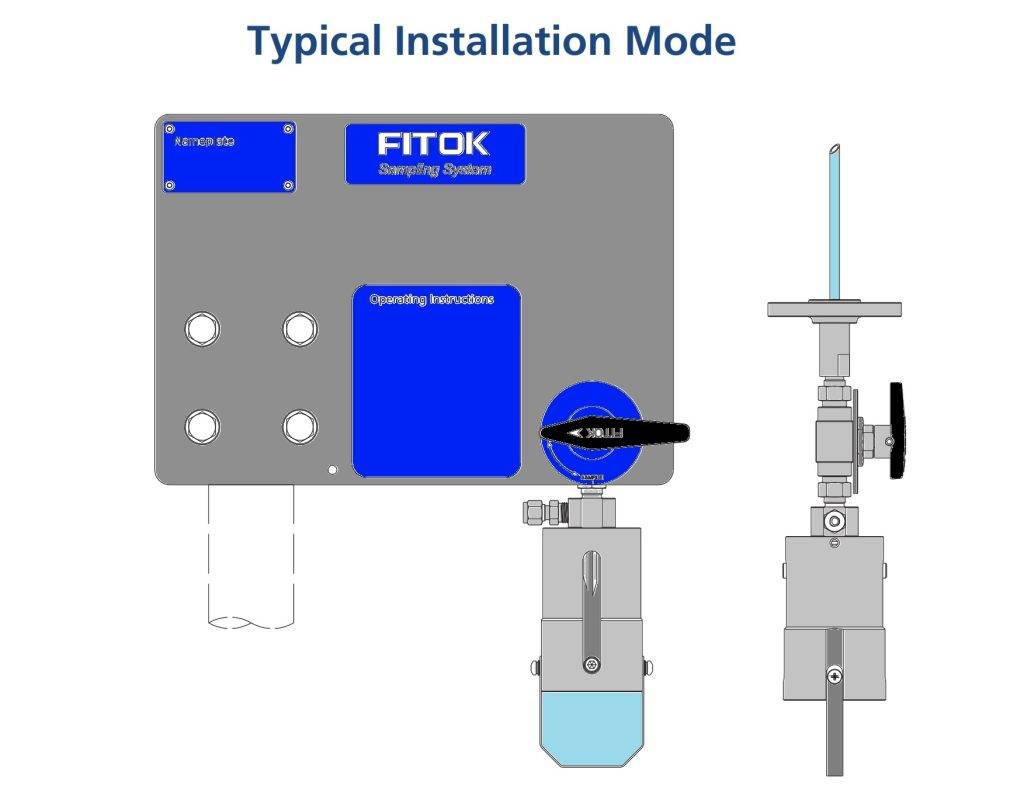

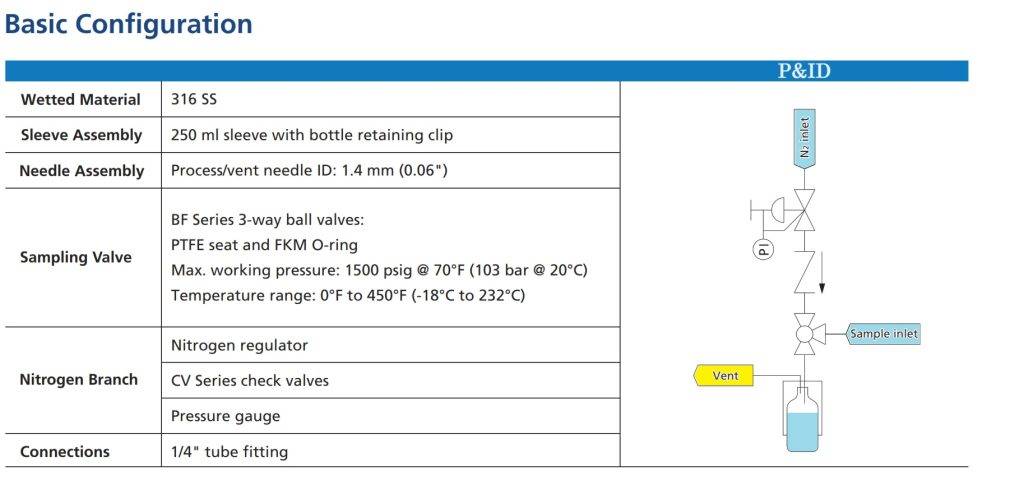

BLA 1-On-off Type

Features

© Sampling from low pressure devices or process lines: 0-145 psig (0-10 bar)

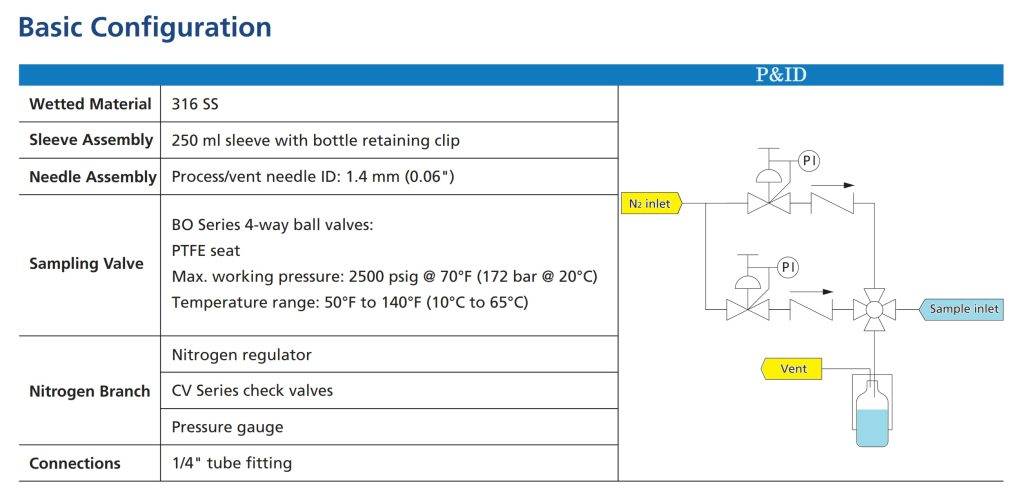

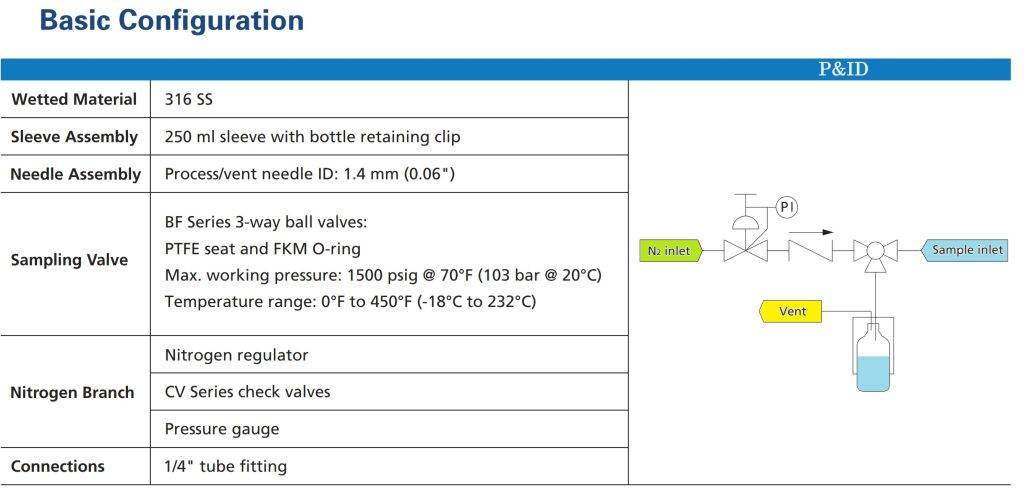

BLA2 – System Purge Type

Features

© Sampling from low pressure devices or process lines: 0-145 psig (0-10 bar)

© System purge

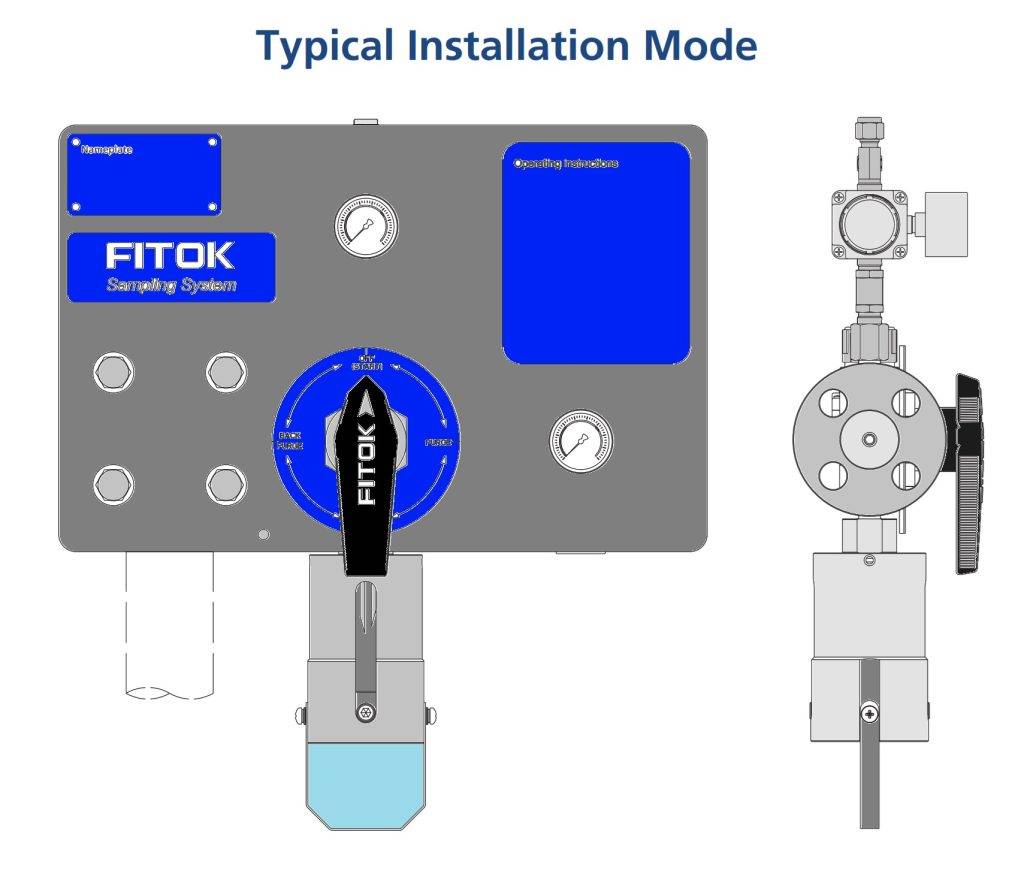

BLA3 – Back Purge Type

Features

© Sampling from low pressure devices or process lines: 0-145 psig (0-10 bar) Back purge

BLA 4 – Needle Purge Type

Features

© Sampling from low pressure devices or process lines: 0-145 psig (0-10 bar)

© Needle purge

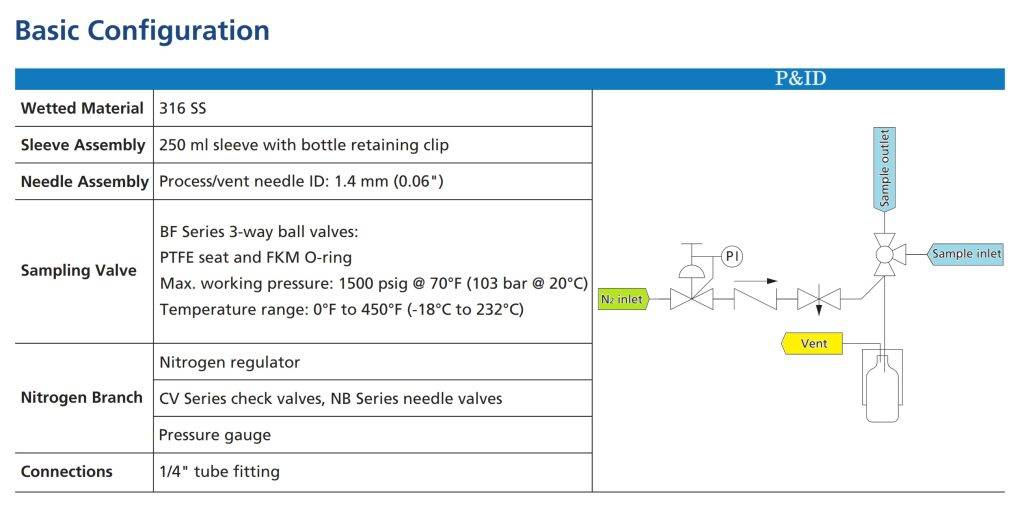

BLA5 – Back and Needle Purge Type

Features

© Sampling from low pressure devices or process lines: 0-145 psig (0-10 bar)

© Back purge and needle purge

BLA5-BACK AND NEEDLE PURGE TYPE CATALOGS

BLA6 – System Purge and Continuous Needle Purge Type

Features

© Sampling from low pressure devices or process lines: 0-145 psig (0-10 bar)

© System purge and continuous needle purge

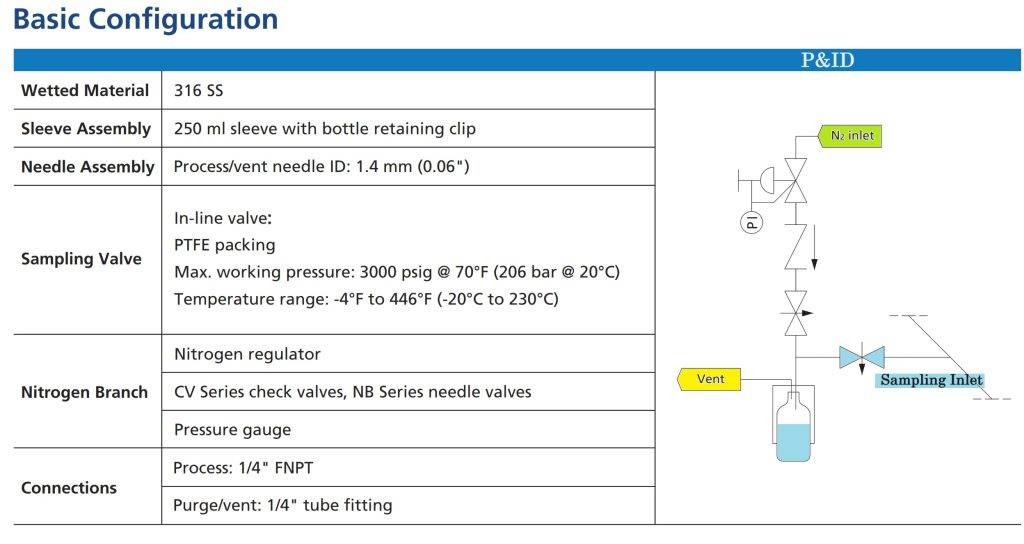

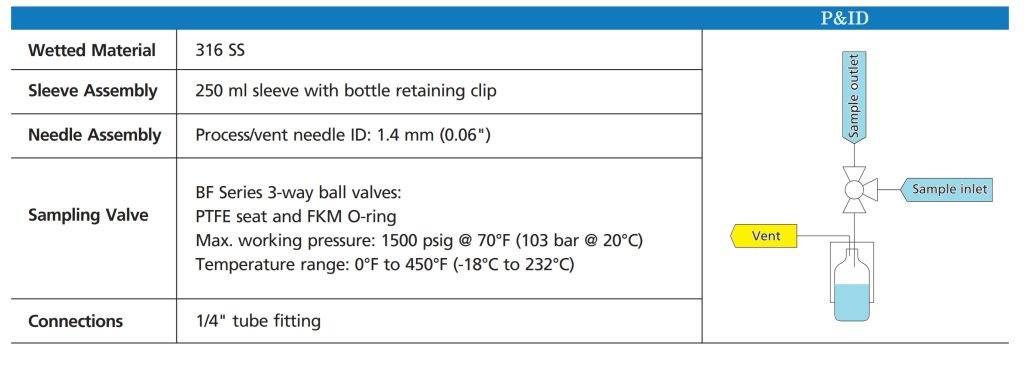

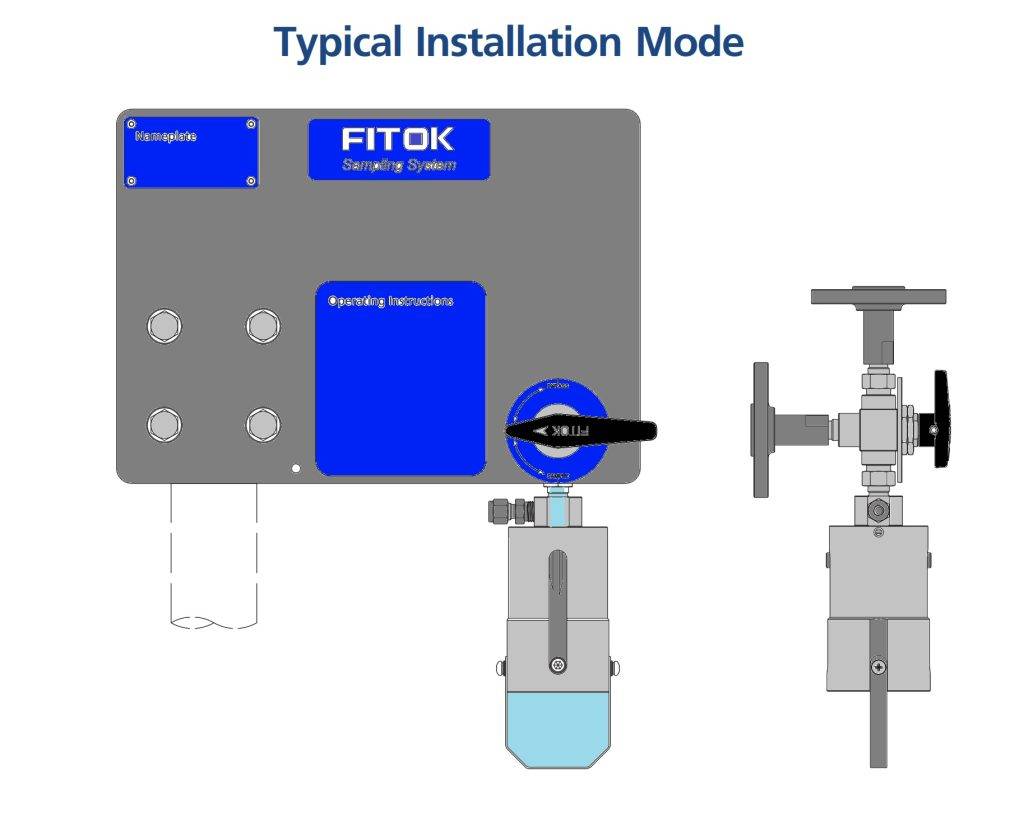

BLA 7 – In-line and Needle Purge Type

Features

© Sampling from low pressure devices or process lines: 0-145 psig (0-10 bar)

© In-line sampling valve to save sampling time

© Needle purge

Sampling Process Video