Coiled Tube Precision Engineered

Seamless and Weld and Drawn Products

FITOK products Coiled Tube is manufacture as seamless according to ASTM A213 or EN10216.5, as welded and drawn according to ASME SA249, ASTM A269 or EN10217.7.

FITOK welded product types are “cold drawn and weld bead perfect remove” to earn the trademark of Welded as Seamless.

The high precision cold drawn product is category primary services the with following industries :

1.Oil & Gas

2. Oil refining and Petrochemicals

3. Downhole Services

4. Subsea exploration

5. Fire resistant

6. Pre insulation

7. Metal insulation.

The most critical value of FITOK program of quality management is the honest and predictable approach to quality assurance and controls.

FITOK team adheres to the conviction that there is no shortcut solution in quality assurance but only doing quality works by the book is the most resource efficient road for success.

Corrosion resistance

General corrosion :

FITOK has good resistance to

1. Organic acids at high concen trations and temperatures

2. Inorganic acids.

e.g. phosphoric and sulphuric acids, at moderate concen trations and temperatures. e.g. sulphates, sulphides and sulphites.

Intergranular corrosion

Low carbon content and therefore better resistance to intergranular corrosion than other steels of type AISI 316.

Pitting and crevice corrosion

Resistance of these types of corrosion improves with molybdenum cont ent, and has substantial higher resistance to attack than steels of type AISI 304.

Stress corrosion cracking

Austenitic steels are susceptible to stress corrosion cracking.

Stress corrosion cracking may occur if the steel is simultaneous expose to the following :

1. Tensile stresses.

2. Certain solutions, particular those containing chlorides.

3. Temperatures above 60°C (140°F).

In some applications demanding high resistance to stress corrosion cracking, ferritic austenitic steels, e.g. SAF 2304 or SAF 2205 are recommend. See data sheets S1871ENG and S1874ENG.

Bending

Annealing after cold bending is not normal necessary, but this point must be decide with regard to the degree of bending and the operating conditions. Heat treat m ent should take the form of stress relieving or quench annealing, see under ”Heat treat m ent”.

Hot bending is carried out at 1100 until 850°C (2010 until 1560°F), and should be follow by quench annealing process.

Welding

The weld ability of TCT is good. Suitable welding methods are manual metal arc welding with cover electrodes and gas shielded arc welding with the TIG and MIG methods as first choice. Preheating and post weld heat treat m ent are not normal necessary.

Since the material has low thermal conductivity and high thermal expansion, and welding must be carried out with a low heat input and with welding plans well thought out in advance, so that the deformation of the welded joint can be kept under control. If despite these precautions, it is fore seen that the residual stresses might impair the function of the weld, we recommend that the entire structure be stress relieved. See under ”Heat treatment”.

As filler material for gas shielded arc welding, we recommended wire electrodes and rods, when a ferritic free weld metal is required. In manual metal arc welding covered electrodes is recommended.

TCT Series FITOK COILED TUBE

Features

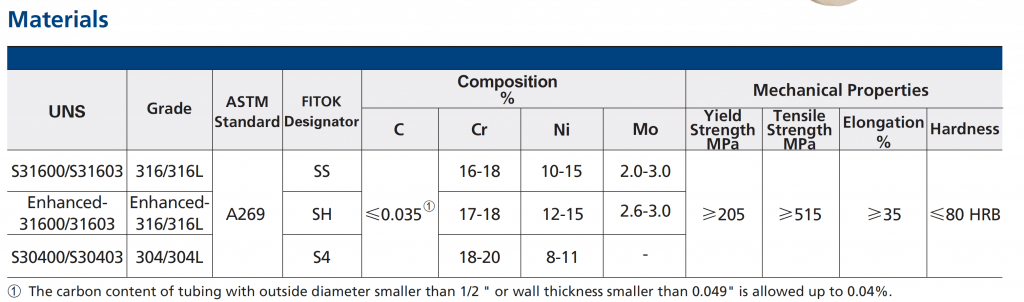

1. Materials come from 316/316L, and enhanced 316/316L or 304/304L.

2. Sizes from 1/4″ to 1/2″ and 6 mm to 12 mm.

3. Working temperature from-325°F to 1000°F (-198°C to 537°C).

4. Bright annealed with mechanical polished external surface.

5. For use FITOK 6 series tube fittings, 4:1 safety factor for the tubing and connection part of fitting and tubing.

6. Marked with brand, material grade, standard, specification and heat number.

We are PT. Solutec Daya Mandiri is ready to serve you to provide high quality Coiled tube. Please contact us.