37° Flare Tube Fitting

Features Flared Tube Fitting

- Flare Fitting are designed and manufactured in compliance with SAE J514.

- Sizes range from 1/8″ to 2″ and 3 mm to 50 mm.

- 316 stainless steel, aluminum, brass, and carbon steel materials are available.

- Hardened threads and smoothed surface finishes extend fitting life and prevent sticking of the matching threads.

- Radius junction design within elbows provides smooth flow path.

- Every fitting is stamped with size, material and heat code.

- Four times safety factor applied for above working pressure.

- Female nut threads are silver-plated to minimize the friction with body threads.

- Fittings are easy to disconnect and retighten.

- The working temperature of FITOK 37 flare tube fittings is the same as that of FITOK 6 series tube fittings.

- Cautions :

* Do not loosen or tighten fittings when system is pressurized.

* Always use proper thread sealants on tapered pipe threads.

* Confirm the sealing type when choosing the straight threads, make sure the construction of the matching threads comply with the sealing type.

Cautions :

◎ Do not loosen or tighten fittings when system is pressurized.

◎ Please use proper thread sealants on tapered pipe threads.

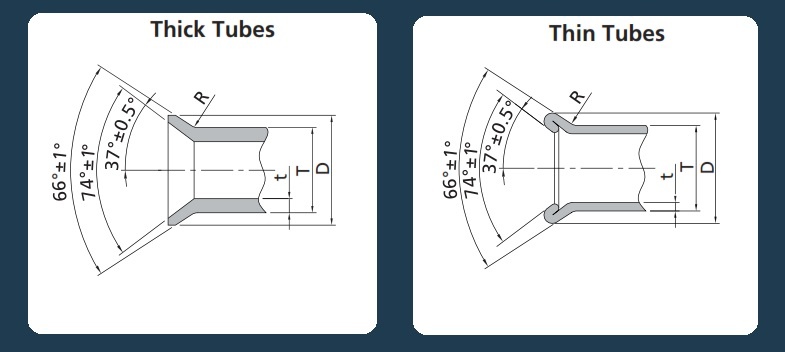

Flaring Operation

Tube flaring is carried out in two different ways, “single wall flare” on thick wall tubes and “double wall flare” on thin wall tubes to reinforce same. Refer to the table below.

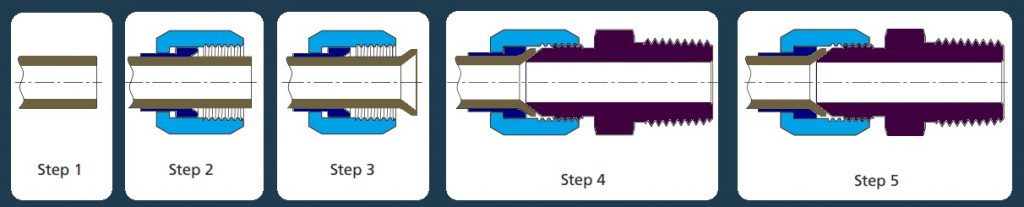

Installation Instructions.

1. Cut the tube to the proper length.

2. Insert the tube into the nut and sleeve.

3. Form the flare to 37° dimension according to SAE J533. See flaring operation.

4. Finger-tighten the nut.

5. Tighten the nut 1/4 turn with wrench while holding steady the body of the fitting.

Download Catalog

Related Product

Download Catalog

Related Product