Instrument Tubing

Tubing stainless steel for instrumentation systems, many tyep with variation of material and thickness

Instrument Tubing size divide two category for type of size that is fractional and metric, and Imperial sizes and in accordance with global specifications Instrument tubing size. Chemically cleaned and passivated is to comply with ASTM G93 Level A and CGA 4.1

Thermocouple cleaned here is to meet the cleanliness requirements of ASTM A632-S3.

Tubing is Available in TMP series and TCT series.

- TMP series seamless straight length is pickled or bright annealed treatment and have external surface with mechanically polished.

- TCT series seamless coiled is tubing bright annealed treatment, with external surface mechanically polished.

- Materials : stainless steel, duplex stainless steel or Nickel with based alloy. Additional with Enhanced-316/316L, with Ni, Cr and Mo contents in close.

Packing

◎ Seamless Straight-length

Instrument Tubing ends polyethylene capped and tubing bulk packed in cardboard tubes or wooden cases.

However, in between the two processes, TBA series tubing should be additionally packed in a single polyethylene bag, and TEP series tubing in double polyethylene bags.

◎ Seamless Coiled Tubing

Two kinds of packaging methods tubing ends polyethylene capped; tubing packed in coils and wrapped with a polyethylene film.

Tubing ends polyethylene capped; tubing packed in coils on wooden reel and firmly anchored by a polyethylene plate. The first packaging method is standard, if packaging with wooden reel is needed.

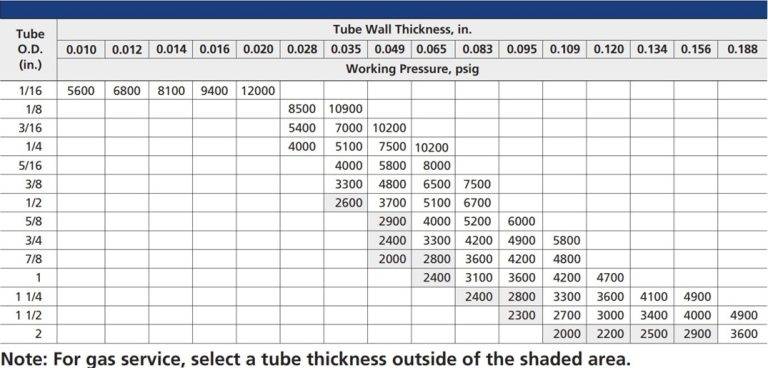

Working Pressure

Instrument Tubing size is have working pressures are calculated based on standard ASME B31.3. How to determine working pressures at elevated temperatures with multiply the working pressures at ambient temperature by the elevated temperature factors.

Browse Our Catalogs Instrument Tubing

Other Tubing Product

Tubing General Information

SDM Company Brochure

How to Install Tubing with Tube Fittings

Seamless Tubing Selection

FITOK Manual Tube Bender

Instruction How to used Tube Deburring

How to Cutting Tube