Leak of valve Introduction

Leak of valve are a common problem in fluid systems. Technically speaking, it is impossible for systems to be 100% leak-free. However, in applications with a high degree of purity, even the smallest leak can affect the smooth operation of systems, meaning that high demands must be place on the leak rates of the components.

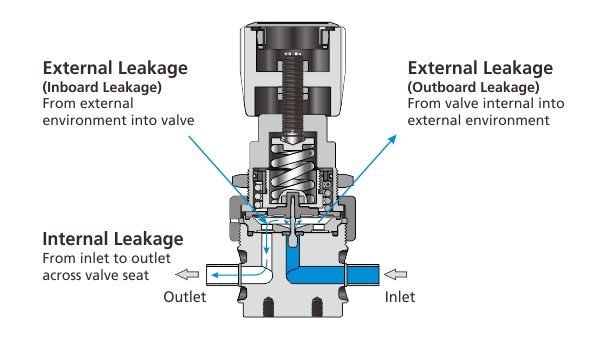

Generally differentiate between internal and external leak rates.

- The term internal leakage refers to the leak that occurs within a piping component such as: B. the leakage of medium through the seat of a closed valve.

- External leakage is a leak between a pipeline component and the external environment and can be divide into internal and external leakage. An internal leak is a leak from the external environment into the piping system, e.g. in vacuum applications or when the internal pressure of the system is lower than the ambient pressure. An external leak, on the other hand, is a leak from the piping system into the external environment – when the internal pressure of the piping system is greater than the pressure of the external environment.

External and Internal Leak of Regulator Valve

When selecting high-purity products, it is important to consider the different internal and external leakage. The requirements valves have maximum internal and external leakage rates of 1×10-9 std cm3/s. To determine if a valve has an internal leak, observe whether helium is leaking from the valve’s outlet when closed.

In the event of an external leak, test gas is introduce into the pipeline system and detected on the opposite side. It is important to note that the internal leak test should only take 15 seconds. Helium is very permeable to non-metallic materials, especially common seat materials such as PTFE and PCTFE. If the test duration exceeds this time, some of the helium may penetrate the non-metallic valve seat. This makes it impossible to test the actual leak rate.

Helium Leak Test

Why is helium use as a test medium? First, helium is an inert gas and is consider a relatively safe test medium. Second, helium has comparatively small atoms.

The amount of helium present in the air is also limit to only around 5 ppm, which makes leak testing with helium very precise.

Helium leak testing is a highly specialize, non-destructive testing method used to detect and locate leaks in a system or component. It is the most common way to detect leakage in the industry. 100% of FITOK high purity and ultra high purity valves and regulators. Pass the internal and external helium leak test before delivery to the customer.

The advantage of helium is one of the smallest gas molecules and is inert. Being inert, helium is relatively safe to use (rather than hydrogen) and will not react with any of the materials within the part to be test.

A leak diameter for 1×10-12 std.cm3/s (which equates to 1Å) is also the diameter of a helium molecule, and is the smallest leak rate that can be detect theoretically. Helium leak detector used by FITOK has a minimum detectable leak rate of 5×10-12 std. cm3/s.

Helium leak testing

Leak across between a the seat and permeation

It’s important to distinguish between a leak across the seat and permeation through the seat. After 30 seconds of exposure, the helium molecules will absorb, diffuse, and desorb from the non-metallic seat. Then it is detect by the mass spectrometer. That’s why the time limit for internal leak tests is usually 15 seconds.

The test sequence is also relevant. Because of the helium saturation of non-metallic materials used, do not perform an internal or inboard leak test after an outboard leak test, and do not perform an inboard leak test after an internal leak test. The preferred order of testing: Inboard > Internal > Outboard.

Test Method

| Test Type | Test Type | Test Method | Remark |

| External leak test | Inboard leak | The product is fully open and connected to the leak detector. Spray helium on outside of the product. | |

| External leak test | Outboard leak | The product is fully open and pressurized with the helium. Use a helium probe to detect the leak. | Sensitivity limited by the helium in the atmosphere, typically 5×10-6 std. cm2/s |

| External leak test | Outboard leak | The product is fully open and placed in a vacuum chamber, pressurized with the helium Leak detector pull the vacuum. | Not production friendly. Usually for type test only. |

| Internal Leak test | Across the seat | The product is closed and the outlet is connected to the leak detector. Pressurized the inlet with the helium. | Test time limit is usually 15 seconds. |