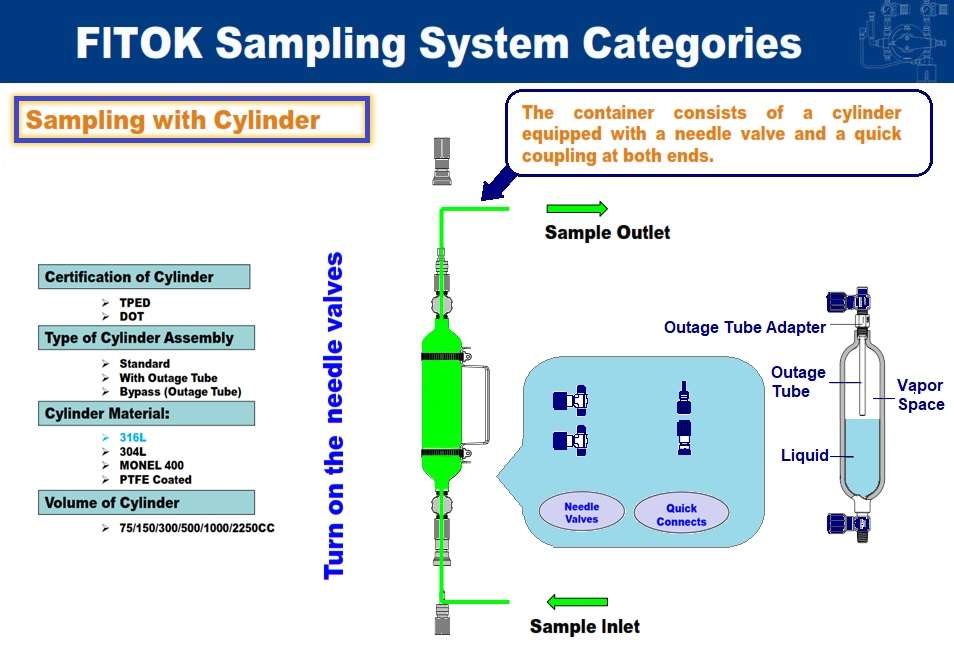

Sample Cylinder

Sample Cylinder Application :

Hydrocarbon sampling for refineries, Gas for chromatography experiments, Condensate for fossil fuel and nuclear power plants, As surge accumulators or reaction vessels, As snubbers in reactor feed lines.

◎ Miniature, ~1000 psig, MC Series

◎ General Service, ~5000 psig, SC Series.

◎ TPED-compliant Cylinders

◎ DOT-compliant Cylinders

◎ Sulfinert (SilcoTek-coated) Cylinders

◎ Spring Relief Device, RT Series

Sample Cylinder Configuration

Sample Cylinder Assemblies

Miniature, ~1000 psig, MC Series

Features

- Maximum working pressure: 1000 psig (69.0 bar)

- Capacities: 10, 25 and 50 cubic cm

- Available for Single-ended and double-ended configurations

- Smooth internal neck transition for easy cleaning

- Stainless steel construction to ensure high corrosion resistance

- Full-penetration butt weld constructions

General Service, ~5000 psig, SC Series

Features

- Capacities from 40 cm to 3785 cm (1 gal)

- Cold-formed female NPT thread to provide high strength

- Available DOT and non-DOT cylinders

- Accessories, such as valves, relief devices, outage tubes, carrying handles, caps and plugs is available

- Spun body machined is made from seamless tubing Furthermore to provide consistent wall thickness, size and capacity

- Full-penetration gas tungsten arc-weld construction to ensure no leak for sampling (single-ended cylinder only)

Options for Internal Cylinder Surface Treatments and Accessories

- TPED-compliant Cylinders.

- DOT-compliant Cylinders.

- Spring Relief Device, RT Series.

- PTFE Coating.

The internal cylinder surface can be coated with PTFE to provide a nonstick surface for easy cleaning. - Electropolishing.

Can provide a clean internal surface with a high degree of passivation.

Sample Cylinders are manufactured in accordance with U.S. Department of Transportation specifications and can be used to sample and transport gases and liquids

◎ Over pressure Protection :

Rupture Disc Kits : This kits protect sample cylinder from over pressurization by venting the gas to atmosphere.

Rupture Disc Tees : These compact assemblies are designed for using with FITOK valves. and Also Tees are made of 316 SS and each tee is supplied with a rupture disc kit.

Valves with Rupture Disc Kits.

◎ Carrying Handle

◎ Caps and Plugs with land yard

◎ End Caps

◎ Outage Tubes

SAFE VALVE SELECTION

When selecting a component is certainly the total system design must be considered to ensure safe, trouble-free performance. Similarly Component function, material compatibility, adequate ratings, proper installation, operation, and maintenance are the responsibility of the system designer and user.

Options for Internal Cylinder Surface Treatments and Accessories