High Pressure Hose Thermoplastic TH Series

High Pressure Hose Application

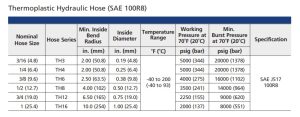

Thermoplastic Hose for Industrial Fluid Applications (SAE J517 100 7R/8R) thermoplastic hose is design to handle a wide range of industrial fluids. The use of thermoplastic materials for the tube, reinforcement, and cover ensures performance capabilities beyond conventional wire-reinforce rubber hose.

Nylon Core

The Nylon core tube is free of manufacturing soapstone or grit and is compatible with most chemicals, solvents, hydraulic oils, and synthetic fluids. The synthetic fiber reinforcement, unlike wire reinforcement, resists fatigue caused by flexing and rugged handling. Thermoplastic hose is also 60% lighter in weight than conventional rubber hoses with wire reinforcement. The rugged polyurethane cover provides for abrasion resistance and longer service life over comparable rubber hose. Unlike rubber hose which cures on the shelf, thermoplastic hose has an unlimited shelf life and is resistant to UV light and ozone. The SAE J517 100 7R hose is available in pressures to 2750 psig (190 bar), and the SAE J517 100 8R hose is available in pressures to 5000 psig (345 bar). Both hoses can be use in continuous service to temperatures of 200°F (93°C).

Hose and pipe installation

Tubing must be properly support and securely clamp, to avoid vibration and movement, threading swarf and cutting burrs must be carefully remove to stop them from breaking loose and being flush into the hydraulic system.

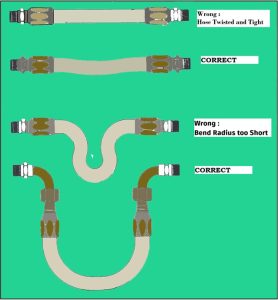

Although hoses are cover with a tough outer layer to reinforce and protect the inner layers, this outer layer should not be abrade or damage. Hose must bend in the same plane as the connection to which it is attach, to prevent twisting. The house appearance does not show whether the recommend minimum bend radius has been excee; the hose reinforcement determines this radius. It is best to check the manufacturer’s specifications prior to installation (fig)

End Connection

End fittings are manufactured to suit the standard thread forms and flanges used throughout the world.

They are further classified as:

* re-usable (subject to serviceability); and

* permanently attached, which is further divide into

– crimp type, where a tubular sheet steel ferrule fixe to the insert is deform to crimp the hose between the ferrule and the insert; and

– pallet-swage type, where a separate, machine ferrule is swage onto the hose end to grip the hose between the ferrule and the insert.

Provide that the fittings are correctly attach, it is generally accept and proven by test results that re-usable as well as permanently attach hose end fittings will outlast the service life of the hose.

Hydraulic Hoses

Hydraulic hose for industrial and mobile use is manufactured to conform to S. A. E. specifications. The two types of hydraulic hose most commonly used are single wire braid (S. A. E. 100 R1) and double wire braid (S. A. E.100 R2), which differ in their pressure ratings. Each type is made in two versions with different thicknesses of the

outer elastomeric layer. They are:

• skive type, with a thick outer layer which must be skived to expose the wire braid prior to attaching the end fitting, e. g. S. A. E. 100 R2A; and

• non-skive type, with a thin outer layer which is not remove prior to attaching the end fitting, e. g. S. A. E.100 R1AT.

End Connection Sleeve and O-ring

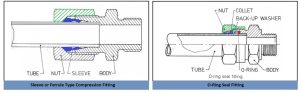

Flare fittings are still widely used, but have lost some ground to compression fittings and O-ring seal fittings. in flare fittings leak tightness is achieve by squeezing the flare end of the pipe against a sealing cone as the compression ring or nut is tighten.

Compression (sleeve) fittings seal by wedging the sleeve onto the pipe and forcing it partly into the pipe surface, so that a slight deformation occurs (fig.). Squareness of the pipe end is not as critical as with flare fittings, and absolute tightness can be guarantee if tightening procedures and specifications are adhered to.

O-ring seal fittings hold the tube by means of a sleeve wedge onto the tube by the nut (fig). The O-ring provides an absolute seal against leakage. Special O-rings must be use for non-flammable synthetic hydraulic fluids.

Hose selection and rating

Since peak or surge pressure spikes often reach 200 per cent or more of the calculate and adjust maxi-mum system pressure, hoses and pipes should be select to withstand such pressure peaks. Three pressure ratings are usually given by the manufacturer: The recommend maximum system pressure (working pressure) at which the hose can be operate continually.

* The test pressure at which a hose is guarantee to withstand pressure peaks.

* The burst pressure at which the house wall rupture.

The S.A. E. recommend working pressure for hydraulic hose is 25 per cent (or one quarter) of the mini-mum specifie burst pressure. This safety margin allows for the absorption of pressure surges. For internal diameter calculations, use the nomogram (fig.) or the formula given for pipe sizing.

- Features

- Technical Data & Optional Acessories

- Construction

TH Series

◎ Polyurethane cover for resists oil, weather and abrasion

◎ Reinforcement for double braid high-strength synthetic fiber

◎ Core tube: nylon

◎ Working pressure up to: 5000 psig (345 bar)

◎ Nominal hose size: 3/16″ to 1″

◎ Working temperature: -40 F° to 200 F° (-40 C° to 93 C°)

◎ End connections: 1/4 to 1 thread, 1/4 to 1 and 6 mm to 22 mm tube fitting

◎ End connection materials: stainless steel, brass and carbon steel

◎ Custom length is available

◎ Thermoplastic Hydraulic Hose (SAE 100R7)

◎ Thermoplastic Hydraulic Hose (SAE 100R8)

Optional Hoses

- Fire Jacket

◎ Braided fiberglass coated with organic, high-temperature-resistant iron oxide red silicone rubber

◎ Operating temperature from -65 to 500°F (-53 to 260°C) with max. short-term exposure temperature to 3002°F (1650°C).

◎ Offers excellent flame and fire protection and has good thermal and electrical insulation with resistance to acid & alkali - Anti-whip Cable

◎ 304 stainless steel cable

◎ Available on hoses without changing the technical data of hoses

◎ Prevent hoses from whipping around and causing serious injuries in the event of fitting blow off or hose burst - Spring Guard

◎ 302 stainless steel material

◎ Provide hoses without changing the technical data of hoses

◎ Protect the hose from abrasion, overbending, and kinking - Testing

Every FITOK thermoplastic hose assembly is factory tested with pure water at 1.5 times the maximum working pressure.

Cleaning and Packaging

FITOK thermoplastic hose components are cleaned in accordance with FITOK standard cleaning (FC 01) for general industrial procedures.

Shorter hoses are packed in cartons with suitable protective material, longer hoses are coiled, bagged and boxed or crated.

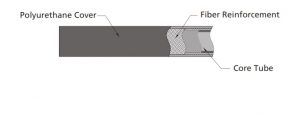

Construction

High pressure hose is a length of tubing made flexible by means of convolutions. It may be readily bent and yet remain gas and liquid tight. High pressure hose is made of Core tube nylon over braid Fiber Reinforcement . The components can be weld to the end of the house. End connections include tube fitting, tube adapter, VCO, VCR and NPT.

- Core tube nylon

- Over braid Fiber Reinforcement

- Polyurethane Cover

Thermo-plastic hose, Polyurethane vover, double braid high strength synthetic fiber reinforcement, nylon core tube. Max working pressure: 2750psig, 1/4″ hose ID. SAE J517 100R7, 63.5M

Hose, 316SS, TH Series Hose, 1/4″ Tube Adapter X 1/4″ MNPT Connections, 800 mm Per Stick

Hose and Connectors, Polyurethane Cover, Nylon Core Tube, 316SS End Connectors, MWP: 3500psig@70° F (20° C),1/2″ Nominal Hose Size, Connection: 1/4″ Female NPT x 1/2″ Male NPT, Overall Length: 1000mm, Hose Code: 100R8.