Trunnion Ball Valves BF and BFH Series

Style of this valve have additional mechanical device with function is to prevent ball blowout and low torque to operated valve. This ball valve is provided automatic relief of cavity over pressure and design with soft seat and metal seat to reduce seat wear from pressure surges Therefore application of this valve is for high pressure and large size of ball valve.

Trunnion Ball Valves variation connection

316 SS, BF Series Ball Valve, 1/4″ Tube Fitting, ( Include Test Report Certificate), 1500 Psig

316 SS, BF Series Ball Valve, 1/4″ Tube Fitting, ( Include Test Report Certificate), 1500 Psig

Ball Valve BF Series 316SS, MWP: 6000psig? working temp: -17 to 232deg C. orifice: 4.8mm. 1/4″ Tube OD. Seat: PEEK

Ball Valve ¼” FNPT PEEK 6000psi, ( Include Test Report Certificate)

Ball Valve, 316 SS, BF Series Ball Valve, Trunnion, PEEK Seats, 1/4 Female NPT ×1/4 Female NPT × 1/4 Female NPT, 6000psig(414bar), 0°F to 450°F(-18°C to 232°C), 0.75 Cv, 3-way

Ball Valve, 316 SS, BF Series Ball Valve, Trunnion, PEEK Seats, 1/4 Female NPT ×1/4 Female NPT × 1/4 Female NPT, 6000psig(414bar), 0°F to 450°F(-18°C to 232°C), 0.75 Cv, 3-way

Ball Valves, Body:316SS, MWP:6,000psig, Seat:PEEK, Conn.:6mm x 6mm Tube OD, 2-Ferrule, Orifice:4.8mm, Cv:1.6,90 Normally Closed Spring Return Pneumatic Actuator,Mechanical Limit Switch and Solenoid Valve.

Ball Valves, Body:316SS, MWP:6,000psig, Seat:PEEK, Conn.:6mm x 6mm Tube OD, 2-Ferrule, Orifice:4.8mm, Cv:1.6,90 Normally Closed Spring Return Pneumatic Actuator,Mechanical Limit Switch and Solenoid Valve.

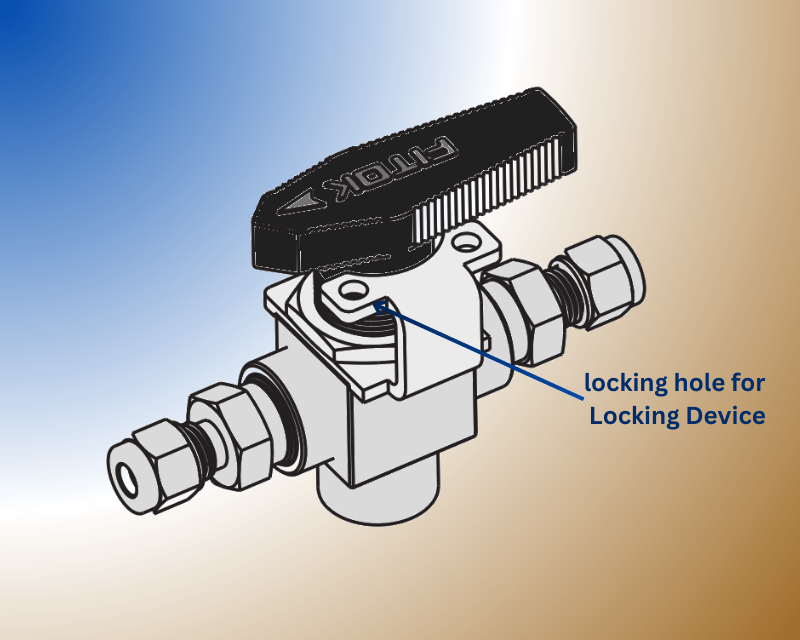

Lock BF series 2-way or 3-way valves, locking hole diameter is 0.21 in (5.2 mm).

To order a ball valve with locking device, add -L to the valve ordering number.

Example: BFSS-ML6-L/BFSS-ML6-3-L

- Features

- Construction Features

- Special Application Ball Valves

Features

Working pressure up to: 10,000 psig (690 bar)

Working temperature: 0°F to 450°F (-18°C to 232°C)

Maximum working pressure of BFH Series ball valves is 10,000 psig.

The specified pressure rating is restricted by end connections.

Orifice size: 0.19″ (4.8 mm)

Fixed ball with double sealing

Trunnion-style ball to prevent ball blowout

Automatic compensation of seat sealing

Low operating torque

Blowout proof stem

Handle as indicator of flow direction

Positive handle stop◎ Handle color options available

Pneumatic and electric actuator available

Panel mountable

Leak-tight performance testing with nitrogen or compressed air for every to valve at the rated pressure (not higher than 6000 psig) meet the requirement of no visible leak

Compact maximum-flow design

2- or 3-way flow patterns

Spring-load seats to provide leak tight integrity in both low-and high-pressure systems and reduce seat wear from pressure surges

The inlet of 3-way valve can be any port

Low-temperature service option available

BF series ball valves with ECE R110 type approval available

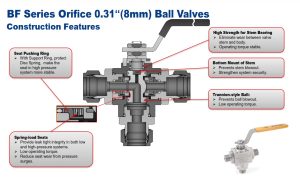

Seat Pushing Ring

- Support Ring, protect Disc Spring, make the seal in high pressure system more stable.

Spring-load Seats

Spring-load Seats

- Provide leak tight integrity in both low and high-pressure systems

- Low operating torque

- Reduce seat wear from pressure surges

High Strength for Stem Bearing

- Eliminate wear between valve stem and body.

- Operating torque stable.

Bottom Mount of Stem

- Prevents stem blowout.

- Strengthen system security.

Trunnion-style Ball :

- Prevents ball blowout.

- Low operating torque.

Special Application

CNG/NGV Application

Classification: Class 0

BF series ball valves with ECE R110 manual valve type approval available .

Temperature rating: -40°F to 248°F (-40°C to 120°C)

Pressure rating: 3370 psig (260 bar)

CNG/NGV application valves have low-temperature FKM O-rings and PEEK seats. All other materials are the same as those of standard valves.

Low-Temperature Service

BF and BFH series ball valves for low-temperature service, with a temperature rating of -40°F to 200°F (-40°C to 93°C), are available.

Low-temperature service valves have low-temperature NBR O-rings. All other materials are the same as those of standard valves.

To order a valve for low-temperature service, add -LT into the valve ordering number.

For example: BFSS-FL4-P-LT, BFSS-FL4-P-3-LT

“Fast Fill” CNG Filling Station Application

BF series 3-way valves for use in “fast-fill” CNG filling station as well as a variety of filling station applications are available.

Features

◎ A directional installation with 90 degree actuation for ease of operation during filling

◎ 3-way design with vent port for ease of venting after fill

◎ PEEK seats to reduce maintenance required in high-cycle applications

◎ Cycle life test report available upon request