Cutting Tube

There are two common methods of tube cutting :

- Tube Cutters

- Hacksaw

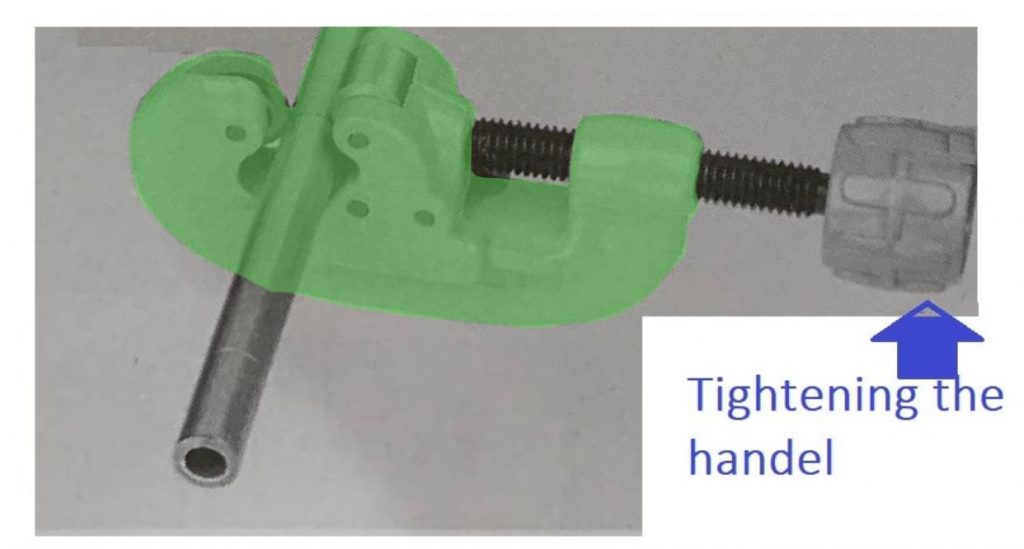

Tube cutters generally consist of a frame and handle which screw mechanism with advance the cutting wheel which the cutting wheel and rollers to support the tube during the cutting operation.

Such cutters are commonly use for the cutting of plastic, soft copper and aluminum or perhaps Soft steel tubing. Good quality cutter wheels use on soft tubing and provide a long service life before dulling.

Most tube cutters do not have a cutter wheel and designed for use on harder tubing materials such as stainless steel and therefore it’s not recommend while use on such hard tubing.

TUBE CUTTER

Tube cutters do not remove material but rather “push” material aside and down. The duller cutter wheel and the more material is raise at the tube end and increasing tube OD at the end. In its worst case, this raised material can even make it difficult to insert the tube into precision tube fitting components. A dull cutter wheel also work hardens the area of the tube near the cut due to excessive pressure from back-up rollers.

The tube cutter is specifically design to cut annealed steel and stainless steel tubing as well as softer tube materials. Its cutting wheel was develop specifically to overcome and the disadvantages of previously available wheels, giving long life and excellent cuts on steel and stainless steel tubing from 3/16 in. to 1/2 in.

OD. It can also be used for cutting softer tubes such as copper or aluminum up to 1 in OD.

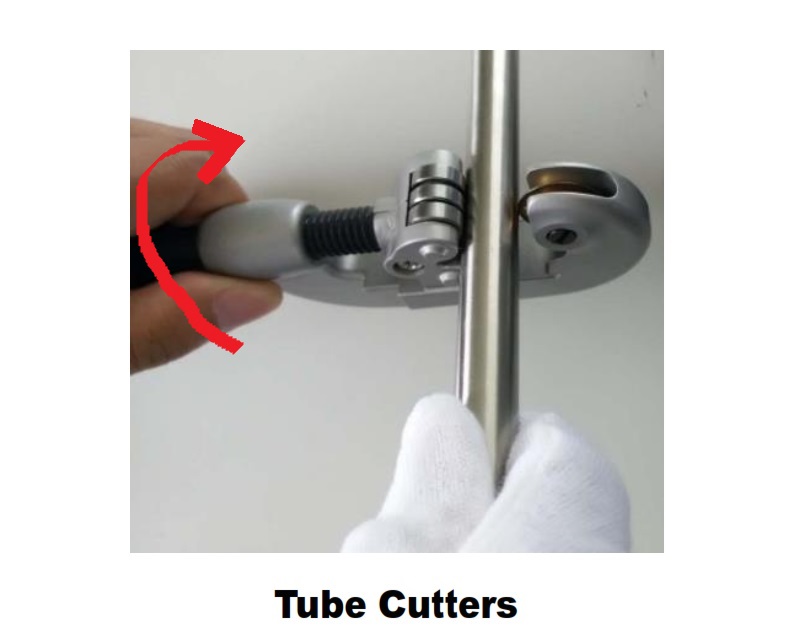

HOW TO CUT TUBING WITH USED A TUBE CUTTER

Pressure on the cutter wheel is maintained by a constant and gradual tightening from the handle or knob to advance the cutter wheel deeper into the tube. Trying to rush this procedure will result in poor cuts and excessive cutter wheel wear. We have found that about a 1/8 turn of the knob for each two revolutions of the cutter as optimum for steel or stainless steel tubing. For soft copper tubing a 1/8 turn of the knob for one cutter revolution is sufficient.

Cutting Methode

There are two opinions as to whether tube cutting should be a constant turning or a back and forth motion. On longer lengths of tubing, rock the tube cutter with your band. First rotate above the tubing which will allow you to cut the tubing without taking your hand off the tube cutter. The cutter hand wheel can be adjust as the rocking proceeds to maintain even tension on the cutting wheel. When cutting a short piece of tubing, the cutter may be continually rotated around the end of the tubing. The hand wheel can be gradually rotate to maintain even tension on the cutting wheel. It is important that the cutting wheel be in top condition, and it is recommend that spare, sharp cutting wheels be kept available at all times. When extra resistance is felt due to wheel dulling, the cutting wheel should be replaced.

Cutting Tube

ADDITIONAL TOOLS TUBE CUTTING WITH A HACKSAW

If a tube cutter of the proper size is not available, a hacksaw can be used (see Fig E.. Tubing should always be cut to length with a square cut. When using a hacksaw to cut tubing, use guide-blocks to ensure a square cut and to keep the tubing from flattening out. The tube saw guide is an excellent device to hold tubing while cutting with a hacksaw. Hacksaw blades should have at least 24 teeth per in

Hacksaw and guide blocks used to cut tubing.

Tube cutters throw a burr into the ID of the tubing and a hacksaw will burr both the ID and OD from the tube. These burrs should be remove after cutting the tube. Make sure that metal chips are clean from the end of the tubing since metal chips can cause a fitting to leak or cause damage to components in the system.

Recent Posts

Please Download our Tools Catalog for your reference.

We are PT. Solutec Daya Mandiri is ready to supply Cutter Tubing with variation material request to your installation needed, Please Contact us.