Home > Products Categories > Sampling System>Sampling with Bottle

Bottle Sampling for Liquid

Bottle Sampling Configuration System

◎ Configuration: The container consists of bottle, sealed septum and cap; the sampling loop consists of tubing, valves and fittings.

◎ Operating principle: When sampling, open sampling valve, samples can flow into the sample bottle under system pressure, while air and gases in the bottle are being vented through the vent port. Watching through the window on the protective sleeve, when the required amount has been taken, turn off the sampling valve, the sampling process is complete.

◎ General technical parameters:

– System main body material 316 SS

– Connections 1/4″ tube fitting, 1/2 NPT, NPS 1/2 Flange

– Orifice: 0.19″ (4.8 mm)

– Maximum working pressure:1450 psig (100 bar)

– Working temperature range:0°F to 450°F (-18°C to 232°C)

◎ Applicable working condition High temperature, high pressure, high viscosity, strong corrosive, strong toxicity and dangerous liquid bane to the environment.

◎ Mounting type Direct-mounted, wall-mounted, support bracket, clamping slot, rail-style.

◎ Sampling from pipelines, reactors, tanks, etc.

BLA Series

BLB Series

BLC Series

BLD Series

Definitions

High pressure regulator is a control valve that reduces the input pressure of a fluid to a desired value at its output. When the medium conditions (inlet pressure, medium flow) change, the regulator can still maintain a stable outlet pressure and flow within a certain range.

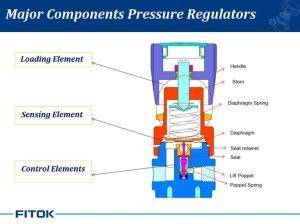

Major Components

- Loading element : Used for the operator to set the outlet pressure of the regulator by applying a loading force. Mainly the handle, valve stem, range spring.

- Sensing element : By sensing the pressure changes in outlet chamber to balance the loading force and the outlet pressure, and physically connect the loading element and the control element.

Types: diaphragm (Figure ) or piston. - Control element : Regulate the relatively high inlet pressure to low outlet pressure, and adjust the orifice size through the stroke of the poppet to maintain a stable output pressure. The control elements mainly include the seat, seat retainer, poppet and poppet spring.

BLE Series