Home > Products Categories > High Pressure Ball valve

High Pressure Ball Valve Subsea

Similar with High and Medium Pressure valve many use in subsea application.

Subsea valves are used to isolate or control the flow of fluid through underwater pipeline or other apparatus. Most commonly used in offshore oil and gas projects.

Design of valve is have function in a sub-marine environment, withstanding the effects of raised external pressure, salt-water corrosion, and other underwater effects. Certain application such as Remotely Operated underwater Vehicle (ROV) or bathyscaphe. Others application High Pressure Ball Valve in Oil and Gas Industry :

- Well-Head Control Panels

- Chemical Injection Skids

- Hydraulic Power Units

- Subsea Work-Over Panels

- Alternative fuel

Paddle Assembly Subsea

Operating valves in a subsea environment use several of electric, hydraulic, or manual actuation. The type of actuation is always dependent on the system and the application. Manual and ROV is manipulated valves with provides an API 17H compliant valve handle that meets the operating standards of ROV, manipulators and ROV interface tooling, called paddle assemblies. This style of handle is use subsea ball valves, needle valves, and subsea systems, that allow an ROV to function the valve. The material used is a high-grade stainless steel that has excellent corrosion resistance and strength for the harsh subsea environment. Equipped with a limit design, the paddle assembly prevents ROV over-torque from affecting the normal use of the valve. With a modular approach, the paddle design will work with nearly every brand and configuration of subsea instrument valves on the market.

Difference between Subsea Valves and General Valves

- Need to consider the material of valve and compatibility of seawater, design external pressure seal structure, solve the influence from seawater pressure to moving parts of valves.

- More difficult to operate and control in seawater.

Causticity of Seawater

● Salinity of seawater is 3%~3.5% :A kind of nature electrolytic quality with strong causticity

● Chloride damage metal passivation film and hinder the form of metal passivation film. - Commonly used materials in seabed : SS 316, Duplex 2205 , Duplex 2507, Inconel 625 with Corrosion resistance gradually increased

- End connection is design with high pressure Fitting.

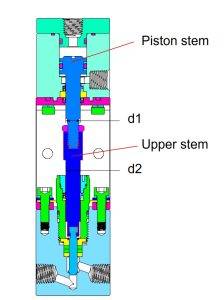

Since seawater has force acting on the components exposed to seawater, effect switch operation of valves.

For example, in FITOK subsea hydraulic needle valves, force direction from seawater to piston stem is upward, to upper stem is downward. Since the both stems have equal diameter (d1 = d2), so the total force from seawater to piston stem and upper valve stem is zero. In this way ,seawater can not effect switch operation of valves.

Subsea Hydraulic Ball Valves

- Features

- Paddle Assembly (PA) Options

Features

- Working pressure up to 20,000 psig (1379 bar)

- Maximum external pressure: 6,000 psig (414 bar)

- NBR O-ring for operation from -10 to 250°F (-23 to 121°C); other O-ring materials available

- High tensile 316 stainless steel or S17400 stainless steel as standard material for valve body

- NACE MR0175 optional

- Paddle assembly (PA) optional

- PEEK seats offer excellent resistance against chemicals, heat and abrasion

- Full-port flow path to minimize pressure drop

- 2-way and 3-way valve configurations

- Bidirectional flow for 2-way valves

- Wide selection of tube and pipe end fittings available

- A variety of wetted materials optional

- Maximum water depth: 13,800 ft. (4200 m)

Paddle Assembly (PA)

Paddle Assembly (PA) installed on the valve, is suitable for ROV or diver operation to complete the opening and closing or reversing of underwater valves.

PA is made of stainless steel, which has good corrosion resistance in the submarine environment. The limit design is adopted in the structure to prevent the over torque of ROV from affecting the normal use of the valve, meeting API 17H specification of ROV interface tooling.

Subsea Hydraulic Ball Valves

- Features

- Operation and Control of Subsea Valves

Features

◎ Working pressure up to 20,000 psig (1379 bar)

◎ Maximum external pressure: 6,000 psig (414 bar)

◎ Hydraulic supply pressure: 3,000 psig (207 bar)

◎ Working temperature: 0 to 200°F (-17.8 to 93℃)

◎ High tensile 316 stainless steel or S17400 stainless steel for valve body and S17400 for hydraulic actuator

◎ Fluorocarbon FKM O-ring and PEEK seal provide excellent resistance against chemicals, heat and abrasion

◎ Three types of hydraulic actuators (HTO, HTC, DH) available

ROV (Underwater Robot)

ROV (Underwater Robot) ROV is a kind of equipment which can move underwater, having visual perception system, using manipulator or other tools to complete the task of

underwater by the way of remote control or autonomous operation .

Hydraulic drive

At present, hydraulic drive is the most widely studied and used in underwater drive way internationally.

Advantages compare to pneumatic drive: small volume, light weight, quick response, high output power, long-distance driving.

Due to the compressibility of gas, pneumatic drive only suitable for short-distance driving, typically used in shallow water depth (<30m).

Subsea Check Valves

- Features

Features

- Working pressure up to 20,000 psig (1379 bar)

- Maximum external pressure: 6,000 psig (414 bar)

- Cracking pressure: 14 to 26 psig (0.966 to 1.794 bar)

- NBR O-ring for operation from -10 to 250°F (-23 to 121°C); other O-ring materials available

- High tensile 316 stainless steel for valve body

- NACE MR0175 optional

- Provides unidirectional flow and tight shut-off for liquids and gases with high reliability. When differential drops below cracking pressure, valve shuts off (Not for use as relief valve)

- Soft seat seal ring style or metal-to-metal seat poppet style available

- Maximum water depth: 13,800 ft. (4200 m)

Subsea Hydraulic Needle Valves

- Features

- Special Design Application

Features

◎ Working pressure up to: 10,000 psig (690 bar)

◎ Working temperature: 0°F to 450°F (-18°C to 232°C)

◎ Maximum working pressure of BFH Series ball valves is 10,000 psig.

◎ The specified pressure rating is restricted by end connections.

◎ Orifice size: 0.19″ (4.8 mm)

◎ Pneumatic and electric actuator available

◎ Panel mountable

◎ Leak-tight performance testing with nitrogen or compressed air for every to valve at the rated pressure (not higher than 6000 psig) meet the requirement of no visible leak

◎ Compact maximum-flow design

◎ 2- or 3-way flow patterns

◎ The inlet of 3-way valve can be any port

Special Design Application Subsea

◎ Fixed ball with double sealing

◎ Trunnion-style ball to prevent ball blowout

◎ Automatic compensation of seat sealing

◎ Low operating torque

◎ Blowout proof stem

◎ Handle as indicator of flow direction

◎ Positive handle stop

◎ Handle color options available

◎ Low-temperature service option available

◎ BF series ball valves with ECE R110 type approval available

◎ Spring-load seats to provide leak tight integrity in both low-and high-pressure systems and reduce seat wear from pressure surges

- Features

- Special Design Application

Features

- Working pressure up to 20,000 psig (1379 bar)

- Maximum external pressure: 6,000 psig (414 bar)

- NBR O-ring for operation from -10 to 250°F (-23 to 121°C); other O-ring materials available

- High tensile 316 stainless steel for valve body

- Standard stem seal material: PTFE

- 2-way straight and angle flow patterns available

- Orifice size: 0.203″

- Rated Cv: 0.75

- Maximum water depth: 13,800 ft. (4200 m)

Special Design

- NACE MR0175 optional

- Using a two-part spindle assembly with a non-rising upper stem, it is of great advantage when being used with ROVs

- Non-rotating lower stem to ensure positive non-galling operation during shut-off

- Packing located under stem threads

- Metal-to-metal seating to ensure ideal shut-off, longer stem/seat service lifetime for abrasive flow, excellent corrosion resistance and greater durability for repeated on/off cycles

- Reliable packing gland locking device

- Wide selection of tube and pipe end fittings available

Subsea Hydraulic Directional Control Valves

- Features

◎ Working pressure up to 15,000 psig (1034 bar)

◎ Pilot working pressure: 3,000 psig (207 bar)

◎ Maximum external pressure: 6,000 psig (414 bar)

◎ NBR O-ring for operation from -10 to 250°F (-23 to 121°C); other O-ring materials available

◎ High tensile 316 stainless steel for valve body

◎ NBR O-rings seal provides excellent oil resistance

◎ Easy to connect, switch off and reverse between different flow channels

◎ Hydraulic remote control for easy operation