Technical information Tube Connector Fittings

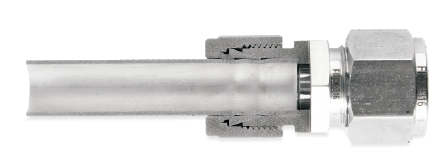

Features Tube Connector with Ferrule

We will descript some of technical information for connection tube connector fittings and material available.

- Sizes range of tube connector is from 1/16″ to ” and 2 mm to 50 mm.

- Diverse materials and configurations are available.

- Precision machined components ensure perfect deformation of the ferrules and tubing.

- Hardened threads with smooth surface finish avoid galling and help to extend the fitting service life.

- Female nut threads are silver-plate to reduce the friction against the body threads

Radius junction design for elbows provides smooth flow path. - Every fitting is marked with size, material and heat number.

- Fittings are easy to disconnect and retighten.

- 1/8″ to 5/8″, 3 mm to 16 mm fittings available with EC-79 certification.

Cautions Installation Tube Connector :

- Do not loosen or tighten fittings when the system is pressurize.

- Make sure that the tubing rests firmly on the shoulder of the port.

- Always leave enough straight length of the tubing for the fittings.

- Always use an insert for extremely soft plastic tubing.

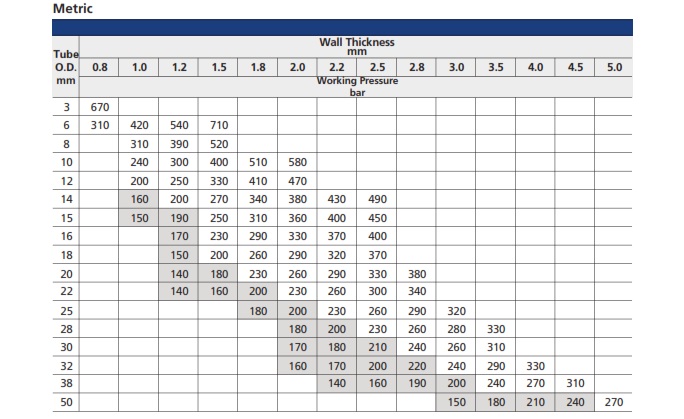

- The allowable working pressure of the tube fitting is rate to the maximum working pressure of the corresponding tubing, which can be found in FITOK tubing data sheet. For those which can not be found in FITOK tubing data sheet, please contact the authorize representatives or FITOK Group for related information.

- Keep the tubing end and surface clean and smooth.◎ Always use proper thread sealants on tapered pipe threads.

- Make sure that its working temperature does not exceed that of the sealants.

- When assembling the tube fitting, hold the body with a wrench and turn the nut instead of holding the nut.

- Installing a valve with tube fitting end, hold the valve body with a wrench and turn the nut.

- Assembling the fitting to a valve with thread, hold the valve body with a wrench and turn the body of the fitting.

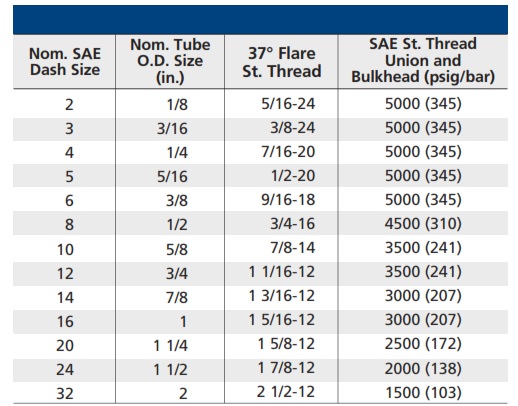

◎ Working Pressures

- The maximum working pressures of the tube connector ends at ambient temperature are determine by the maximum working pressure of the FITOK Tubing that is used. Refer to Tubing on F-02.

- The maximum working pressures of the thread ends at ambient temperature are state as above.

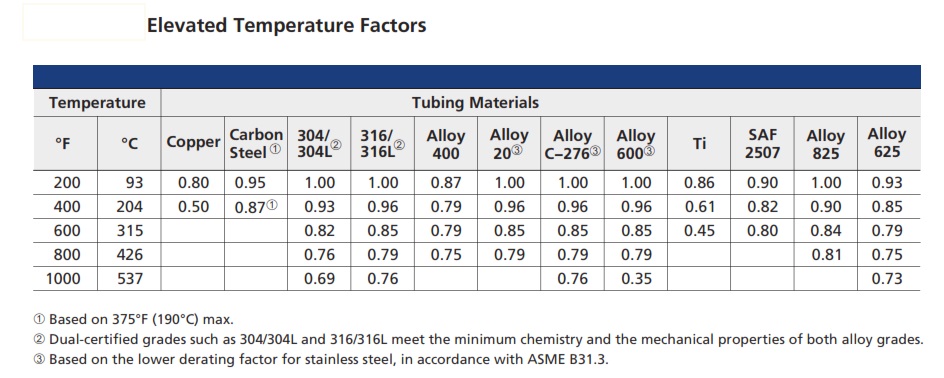

- To get the maximum working pressure at elevated temperature, use the maximum working pressure at ambient temperature to multiply the factors in the table of Elevated Temperature Factors on F-14.

- The maximum working pressure of the whole fitting is determine by the end connection with the lowest pressure rating.

◎ Material

Technical Data

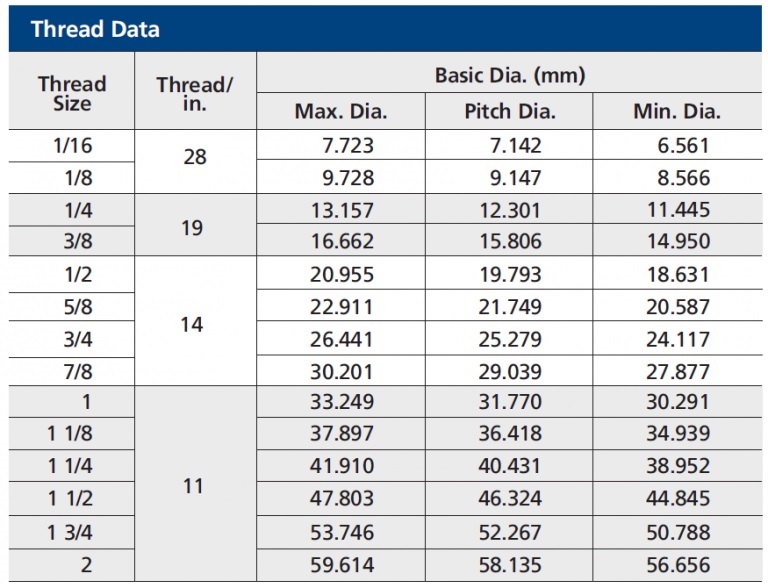

◎ Thread Ends

NPT Threads (NPT)

◎ Comply with ASME B1.20.1, SAE AS71051.

60° thread angle

Pitch measured in inch

Truncation of root and crest are parallel

Taper 1:16

Type of sealing: thread sealant

ISO Tapered Threads (R, R1, R2, Rc, RT, PT, BSPT, ZG)

◎ Comply with ISO-7-1, EN 10226-1, BS 21, DIN 2999, JIS B0203.

55° thread angle

Pitch measured in inch

Truncation of root and crest are parallel

Taper 1:16

Type of sealing: thread sealant

Working Pressure of ISO Tapered Thread Ends

The working pressure of ISO tapered thread ends are the same as that of the NPT thread ends.

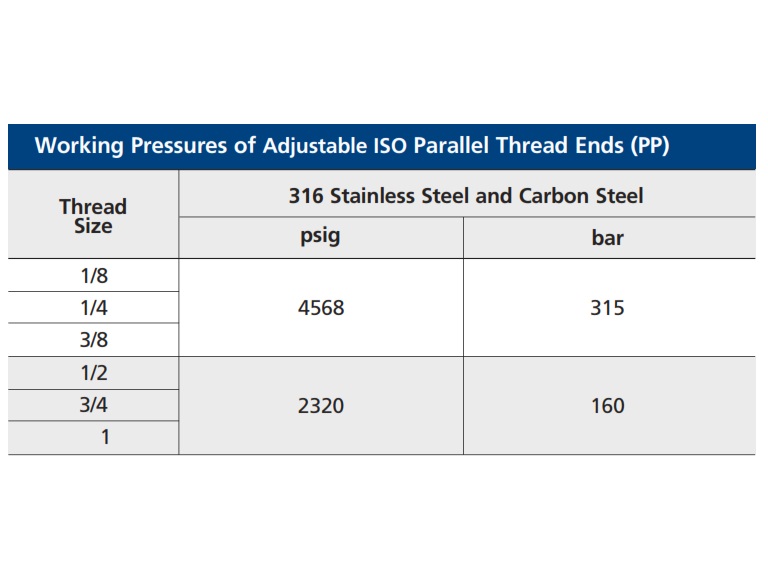

ISO Parallel Threads (G, RP, PF, BSPP)

◎ Comply with ISO 228-1, DIN ISO 228-1, JIS B0202, BS 2779.

55° thread angle

Pitch measured in inch

Truncation of root and crest are parallel

Others Type Tube connector

Flare System

Features

- Flare Fittings are design and manufactured in compliance with SAE J514

- The hardened threads with smooth surface finish avoid galling and help to extend the fitting service lite

- Radius junction design for elbows provides smooth flow path

- Stainless steel nut threads are silver-plate to minimize the friction with the body threads

- Every fitting is mark with size, material and heat number

- Fittings are easy to disconnect and retighten

- All male threads are protect by plastic caps