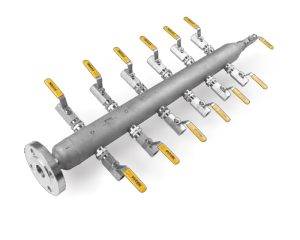

Air Header and Distribution Manifold

Air header are designed to distribute air from the compressor to the actuators on pneumatic instruments, such as steam flow meters, pressure controllers and valve positioners. These manifolds are widely used in industrial pulp and paper, chemical processing, oil and gas processing and energy industries and are approved for low pressure applications up to 1000 psi (threaded or Flange end connections).

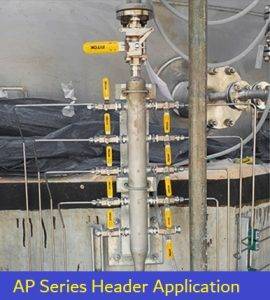

Typically have multiple outlets fitted with ball valves for isolation. When compressed air, steam, etc. contain water vapor to be discharged, can be assembled vertically, and a drain valve (as shown in the following figure) can be installed at the bottom to regularly discharge condensed water from the headers to prevent water from entering the pneumatic instrument. Thus, realizing the functions of air source diversion and distribution.

Key information for selection:

- Process conditions to connected to Flare header

- Connection size and type?

- Is a valve required at inlet?

- Outlet quantity? Is a valve required at outlet? Or valve with plug?

- Is a Atmospheric vent port required? And is a valve or plug required?

- Is mounting bracket required?

- Drain or sewer

Application

The application in air piping system with function is distribute air from main line to instrument equipment is to supply air to operated moving pneumatic actuator. Supply air to purging system with flushing etc.

If we used completed air distribution header include clamp and other accessories you can used Instruction manual link below to install air header.

- Features CM Series Header

- Features AH Series Header

CM Series

- Working pressure up to 6000 psig

- Working temperature:

- PTFE packing: -15 to 450°F (-26 to 232°C) Graphite packing: -15 to 1200°F (-26 to 649°C)

- One-piece, integral body, compact design

- Linear instead of rotary movement of the rising, non-rotating stem minimizes packing abrasion and reduces the friction between the seat and the tip

- Upper stem threads cold rolled and lower stem hardened for high strength and smooth operation

- Fully back seat sealing at fully open position

- Every distribution manifold leak tested at factory with air or Nitrogen at rated working pressure

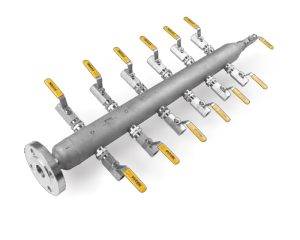

AH Series

- Working pressure up to 1000 psig

- Working temperature: 0 to 250°F (-18 to 121°C)

- Modular design for easy installation and maintenance

- Standard module with 4 or 6 outlets available as an accessory and can be ordered separately

- Multiple choices of inlet and vent types, and in-line replacement available

- Every air header leak tested at factory with air or Nitrogen at rated working pressure

Air Header

316SS, MWP:500psig, Inlet with Valve Connection:1in. (F)NPT, Outlets: 12Ports × 1/4in. Female NPT with Ball Valve, Drain:1/2in. (F)NPT With Plug.

Air Headers, Air Header, 316SS, MWP:1,000psig, Inlet:1/2in. (F)NPT, Outlets:6Ports × 1/2in. (F)NPT with Ball Valve, Drain:1/2in. (F)NPT with Ball Valve

Air Headers AH Series, 316SS Body, 1″ Class150 RF Serrated Flange Inlet, 8 Outlet Quantity,1/2 Female NPT Outlet Connection,1 Inch Female NPT Vent Valve.

Air Headers AH Series,316SS, Inlet Valve Connection: 1″ Female NPT, 10 Outlets, Outlet Valve Connection: 12mm O.D. Tube Type, Vent Valve Connection: 12mm O.D. Tube Type, With Clamp

Air Header AP Series, 316SS Body, 3/4″ Class150 RF Serrated Flange Inlet, 10 Outlet Quantity,1/2 Female NPT Outlet Connection,1/2 Female NPT Drain Valve.

MOC-SS 316 with ball valve 1/4″ Tube Fitting end connection and isolation valve 1″ 12 Way (6 Nos. on Each side) without Clamp

FITOK AP Series, 316SS, MWP:1,000psig, Inlet Valve Connection:1/2″ Male NPT, Outlet Quantity: 4, Outlet Size: 1/4″ Male NPT, Drain Type: 1/2″ Female NPT with Plug.

Air Header AP Series, 316SS, 1″ Class 300 RF Serrated Flange (ANSI B16.5), 12 Outlets, 1/2 Female NPT Connection, 1/2 Female NPT with Drain Plug