High-purity Tube

TBA Series and TEP Series

◎ High purity tube Material: 316L

◎ Standard: ASTM A269 or JIS G3459

◎ Sizes: 1/4″ to 2 1/2″ and 6A to 50A

◎ Process:

TBA series tubing: specially rolled and bright annealed, metallic inner surface finish of Ra 20 μin. (0.51 μm) max.

TEP series tubing: machined from TB series tubing, electropolished inner surface finish of Ra 10 μin. (0.25 μm) max.

◎ Cleaning:

TBA series: ultrasonically cleaned and dried

TEP series: ultrasonically cleaned, washed, rinsed, purged with filtered hot Nitrogen and dried in clean room

◎ Packaging:

TBA series: tubing ends are capped, and tubing is packed individually in a single polyethylene bag

TEP series: tubing ends are capped, and tubing is packed individually in double polyethylene bags

◎ Marking:

TBA series: tubing body is marked with brand, material grade, standard, specification, and heat number

TEP series: packing bags are marked with brand, material grade and specification

◎ Standard length: 20 ft, 4 m and 6 m

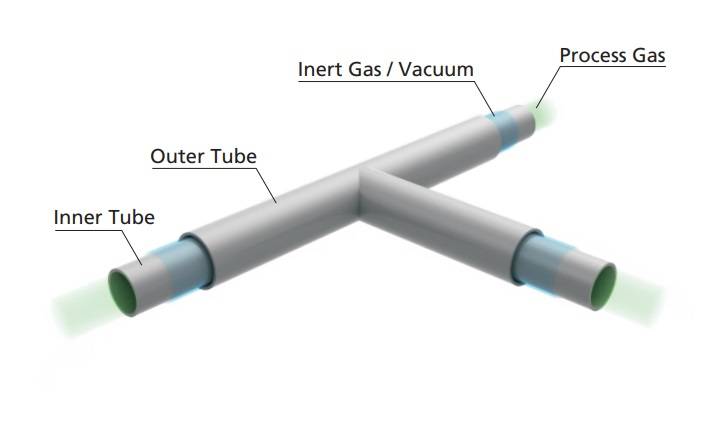

Coaxial Tubing and Fittings, TCA Series

The inner process tube meets the high cleanliness and high performance requirements of ultra high purity fluid systems through strict specifications for raw materials, electropolishing, cleaning and packaging. The outer safety tube provides safe distribution of the overflow fluid in the unlikely event of a leak in the process tube. The double tube system is simple and easy to install with only orbital welding and can be integrated into existing systems and facilities.

Chemically Cleaned and Passivated and Thermocouple-Cleaned Tubing

Chemically cleaned and passivated tubing complies with ASTM G93, Level A requirement for nonvolatile residue levels and also meets requirements of CGA G4.1.

Thermocouple-cleaned tubing meets the cleanliness requirements of ASTM A632-S3.

Tubing General Information

High Purity Tubing TBA Series

Other Tubing Products

TCA Series Coaxial Tubing and Fittings

Related Products

SDM Company Brochure

How to Install Tubing with Tube Fittings

Seamless Tubing Selection

FITOK Manual Tube Bender

Instruction How to used Tube Deburring

How to Cutting Tube